What is a Stainless Steel Mixing Tank?

A stainless steel mixing tank is an industrial equipment, usually made of stainless steel, that ensures the homogeneous mixing of raw materials in liquid and powder form. These tanks are indispensable in the food, pharmaceutical, and cosmetic industries where hygiene standards are critical. Stainless steel, with its corrosion-resistant structure, offers both long-lasting use and easy cleaning.

The biggest advantage of stainless steel tanks is that they do not react with acidic and basic substances. Additionally, they can meet all kinds of production needs with different capacity options and features.

Areas of Use

- Food Industry

Stainless steel tanks are used for mixing products such as yogurt, milk, jam, and sauces. They are an ideal choice with their hygienic structure and heating-cooling options. - Chemical Sector

Stainless steel is preferred for the safe preparation of chemical mixtures due to its material durability and non-reactive nature. - Cosmetics Production

It plays a critical role in mixing and emulsifying products like creams and lotions. - Pharmaceutical Industry

It is one of the most suitable tank types for the sterile and precise mixing of pharmaceuticals.

Stainless Steel Types

304 Stainless Steel:

Used for general purposes due to its chemical resistance and economy.

316 Stainless Steel:

Preferred especially in the chemical and pharmaceutical sectors for its higher corrosion resistance.

Other Alloy Types:

Alloys designed for special needs, resistant to high temperatures and abrasion.

Advantages of a Stainless Steel Mixing Tank

- Durability: Corrosion-resistant structure ensures a long life.

- Hygienic Structure: Ease of cleaning and resistance to bacterial growth.

- Versatility: Wide range of use and production in various capacities.

The Mixing Tank in the Production Process

Stainless steel mixing tanks are indispensable parts of production processes. In the mixing of raw materials, they have several fundamental functions that directly affect the quality of the product:

- Homogenization: Ensures that solid, liquid, or powder materials are completely mixed. A homogeneous mixture plays a key role in maintaining the product’s quality standards.

- Heating and Cooling Processes: Double-jacketed tanks can be used for heating and cooling processes. For example, in jam production, raw materials are first heated and then cooled to be ready for packaging.

- Vacuum and Pressurized Systems: Especially in the chemical and pharmaceutical industries, mixing under a specific pressure may be required. These systems help preserve product properties.

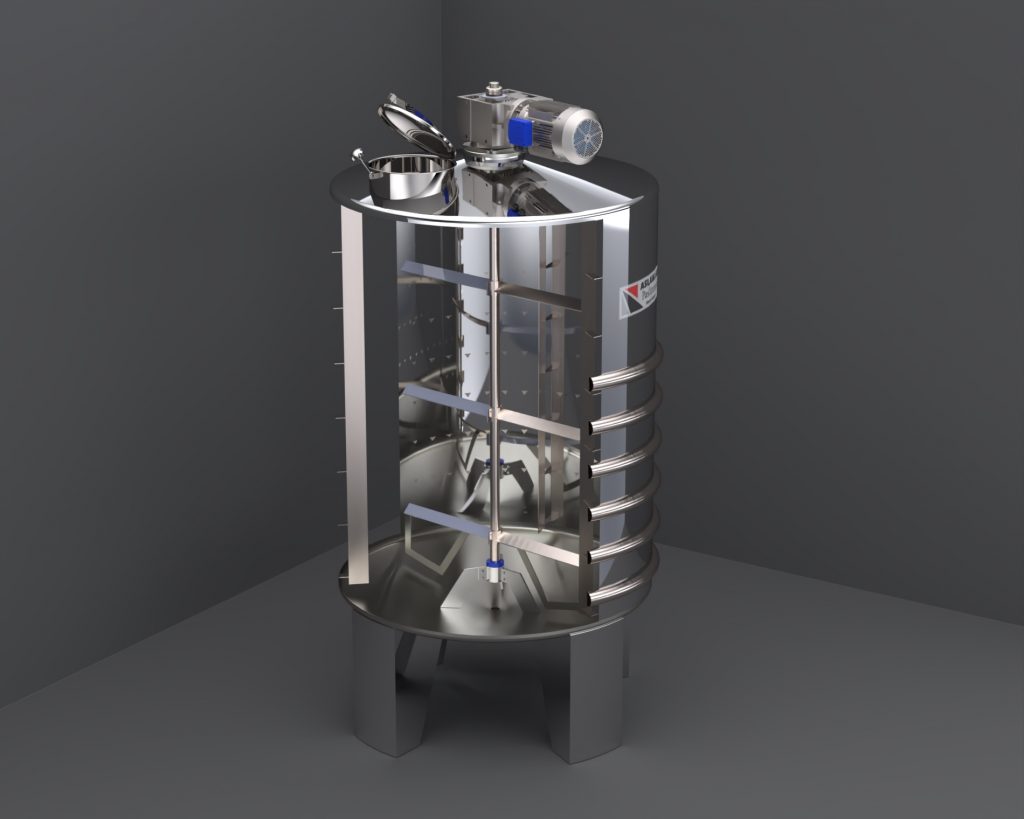

Types of Mixing Tanks

- Horizontal Mixing Tanks

Horizontal tanks are preferred for mixing dense materials due to their large surface area and powerful mixing mechanism. - Vertical Mixing Tanks

Vertical tanks are ideal for creating homogeneous mixtures while saving space. They are particularly suitable for businesses looking for models that occupy less space. - Vacuum and Pressurized Tanks

These models ensure the preservation of sensitive mixtures. They are widely used in the cosmetics and pharmaceutical sectors.

Technical Specifications

Technical specifications to consider when choosing a stainless steel mixing tank:

- Capacity: Options ranging from 50 liters to 10,000 liters depending on the need.

- Motor Power and Rotation Speed: Powerful motors should be preferred for denser mixtures.

- Control Systems: Offers PLC or manual control options. Models that can be integrated with automation systems provide an advantage, especially for large-scale production facilities.

Hygiene and Ease of Cleaning

Stainless steel mixing tanks are designed to meet hygiene requirements:

- CIP Systems (Cleaning-In-Place): These are automatic systems used to clean the inner surface of the tanks. They save time and reduce labor.

- Manual Cleaning: This method, especially suitable for small-capacity tanks, can be easily applied to meet hygiene standards.

Tips for Choosing the Right Tank

Consider the following factors when choosing a stainless steel mixing tank:

- Production Capacity: The capacity should be determined according to the daily production amount.

- Mixing Mechanism: Options like spiral, paddle, or emulsion mixers should be chosen according to the production need.

- Material Quality: The choice between 304 or 316 stainless steel depends on the type of production.

Heating and Cooling Systems

Heating and cooling processes are of critical importance in the production process:

- Double-Jacketed Tanks: These models, used for heating or cooling, ensure that the temperature is distributed evenly.

- Water or Steam-Based Heating: Preferred especially for products requiring precise temperature control.

- Cooling Systems: Rapid cooling is necessary to preserve the quality of the products.

Energy Efficiency

Energy consumption directly affects production costs. Features that provide energy efficiency in stainless steel mixing tanks include:

- Low Energy Consumption: Energy savings are achieved with high-efficiency motors and optimized mixing systems.

- Smart Control Systems: Automation technologies minimize energy consumption.

Stainless Steel Mixing Tank Prices

Prices vary depending on several factors:

- Capacity: Larger capacity models are more costly.

- Material Quality: 316 stainless steel is higher priced than 304.

- Additional Features: Features like vacuum, pressure, and automation increase the price.

Maintenance for Long-Lasting Use

Regular maintenance is important for the longevity of stainless steel mixing tanks:

- Periodic Inspection: The motor, gasket, and mixing mechanism should be checked regularly.

- Fault Prevention: Minor problems should be fixed quickly, otherwise they can lead to greater costs.

Leading Manufacturers

Many leading brands in Turkey and around the world produce high-quality stainless steel mixing tanks.

- Domestic Brands: Affordable options offering high-level quality.

- Foreign Brands: Models with advanced technology.

When choosing a supplier, it is important to check the product warranty and after-sales support services.

Future Trends

With the advancement of technology, the following innovations are emerging in stainless steel mixing tanks:

- Smart Systems: IoT-based tanks offer remote monitoring and control capabilities.

- Automation Technologies: Fully automatic systems for more efficient production processes.

A stainless steel mixing tank is an industrial equipment used to homogeneously mix materials in liquid and powder form.

In food production, it is used to ensure hygienic standards and maintain the homogeneity of products.

316 stainless steel is more durable and has higher chemical resistance than 304.

Prices differ according to capacity, steel type, and additional features.

High-efficiency motors and automation technologies provide energy savings.

CIP systems or manual cleaning methods are used.