Stainless steel tanks are tanks made of stainless steel that offer long-lasting and hygienic storage solutions. These tanks are preferred in many sectors due to their durability and corrosion resistance. The quality of the stainless steel (e.g., 304 or 316) enhances the strength and reliability of these tanks.

Stainless steel tanks are used to safely store many liquid or solid substances, from food products to chemicals, and from olive oil to water.

2. Advantages of Stainless Steel Tanks

The main reasons for preferring stainless steel tanks are the durability, hygiene, and aesthetic advantages they provide. Here are the prominent features of stainless steel tanks:

Durability and Long Life

Stainless steel offers high strength and corrosion resistance. This feature ensures that the tanks can be used for many years without deformation. Its resistance to environmental factors is a major advantage, especially for tanks used in open areas.

Corrosion Resistance

Stainless steel is a material resistant to oxidation. This feature ensures the safe storage of substances such as water, olive oil, and acidic liquids.

Cleaning and Hygiene

Stainless steel surfaces are very easy to clean and prevent the growth of bacteria. Therefore, stainless steel tanks are frequently preferred in the food and pharmaceutical industries.

Sustainability

Stainless steel is a recyclable material. This makes stainless steel tanks an environmentally friendly option. Additionally, their long lifespan minimizes waste generation.

3. Application Areas of Stainless Steel Tanks

Stainless steel tanks are used in a wide variety of sectors. Here are the application areas of these tanks in different industries:

Use in the Food Industry

Stainless steel tanks are ideal for storing food products such as milk, water, fruit juice, and olive oil. Their structure, compliant with hygiene standards, ensures the safe preservation of these products.

Industrial Use

The durability of stainless steel tanks is important for storing chemical substances. Their resistance to acidic and basic chemicals increases safety in industrial processes.

Residential Application Areas

Stainless steel tanks can also be used in homes for water tanks and small-scale storage solutions. It is a safe alternative for garden irrigation or drinking water storage.

Use in the Agricultural Sector

Stainless steel tanks are frequently used for storing agricultural products such as fertilizer or irrigation water. The resistance of these tanks to environmental factors offers a long-term solution for farmers.

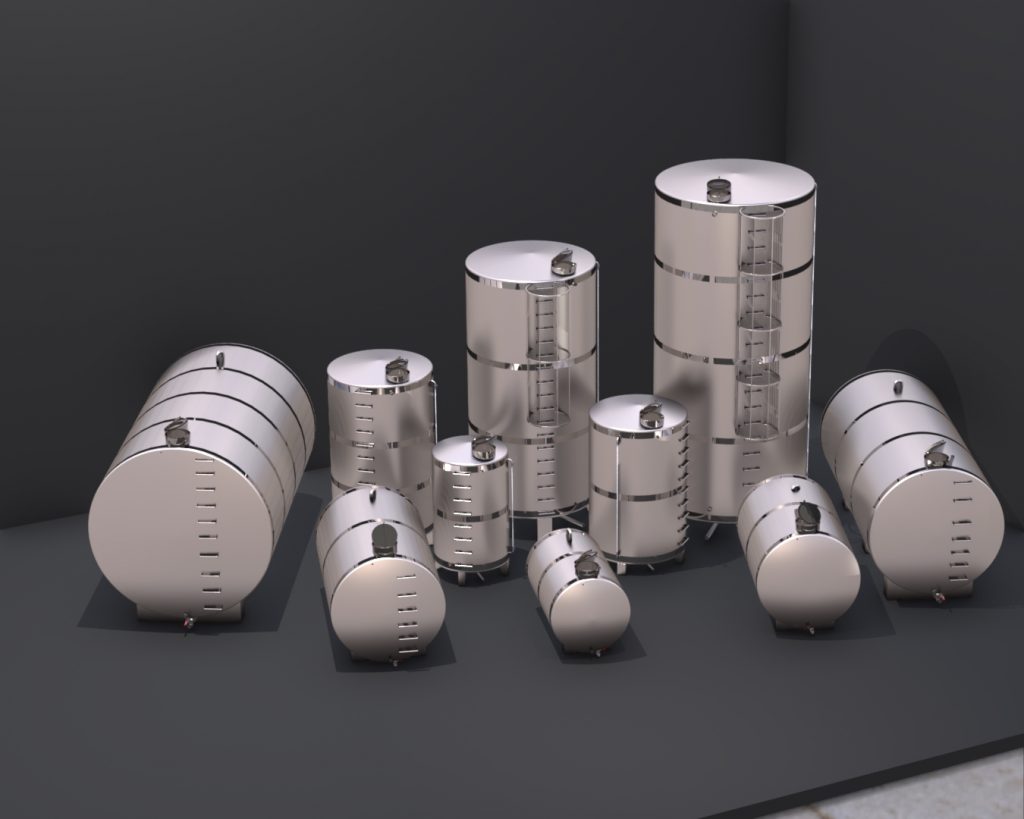

4. Types of Stainless Steel Tanks

Stainless steel tanks are diversified according to different usage needs. Here are the most common types of stainless steel tanks:

Stainless Steel Horizontal Tank Models

These tanks are used in places that require large areas. They generally stand out with their low height and long structure.

Stainless Steel Vertical Tank Models

These tanks, with their vertical structure, offer maximum storage capacity in narrower spaces.

Stainless Steel Prismatic Tank Models

These tanks, in the shape of a rectangular or square prism, offer both aesthetic and functional advantages.

Stainless Steel Tanks for Olive Oil

These models, specially designed for storing olive oil, are produced to preserve the quality of the oil and have a structure compliant with hygiene standards.

5. Stainless Steel Horizontal Tank Models

Horizontal stainless steel tanks are an ideal option, especially for storing large quantities of liquid in wide areas. The prominent features of these tanks are:

General Features

- Horizontal design provides a low height advantage.

- Offers stability during storage.

- Comes in various capacity options (e.g., from 500 liters to 100,000 liters).

Application Areas

- Storage of liquids in food production facilities.

- Irrigation or fertilizer storage in agriculture.

- Industrial chemical storage.

Advantages

- Easy transportation and installation.

- Offers an economical solution with its long-lasting structure.

6. Stainless Steel Vertical Tank Models

Vertical tanks are an excellent choice for users who want to save space. These models take up little space with their compact design and offer high storage capacity.

Technical Specifications

- Positioned vertically.

- Provides maximum storage capacity in small areas.

- The inner and outer surfaces of the tanks are coated with high-quality stainless steel.

Application Areas

- Drinking water storage.

- Industrial liquid storage.

- Hygienic storage in food production facilities.

Production Technologies

Laser welding and automation systems are used in the production of stainless steel vertical tanks. This increases product quality.

7. Stainless Steel Prismatic Tank Models

Prismatic tanks, with their square or rectangular structure, offer an efficient storage solution in narrow spaces.

Shape and Structural Advantages

- Offers ease of stacking due to its shape.

- Provides extra durability in corner areas.

Capacity and Size Options

- Wide options are available, from 100 liters to 100,000 liters.

- Custom designs can be made according to customer needs.

Application Areas

- As a drinking water tank in offices.

- In the food industry for sensitive liquids like olive oil and milk.

8. Stainless Steel Tanks for Olive Oil

Olive oil requires special storage conditions due to its delicate nature. Stainless steel tanks meet these needs in the best way possible.

Olive Oil Storage Needs

- Surfaces with high corrosion resistance.

- Airtight lids.

- Structures suitable for temperature control.

Hygiene Standards

- Use of food-grade stainless steel.

- Bright inner surface that is easy to clean.

Advantages

- Preserves the flavor and quality of olive oil.

- Ideal for long-term storage.

9. Materials Used in Stainless Steel Tank Production

The quality of stainless steel tanks depends on the materials used in their production. The right material selection ensures that the tanks are long-lasting and reliable.

304 and 316 Grade Stainless Steel

- 304 Grade Stainless Steel: Commonly used for storing substances like food and drinking water. It is highly resistant to rust.

- 316 Grade Stainless Steel: Ideal for seawater and more aggressive chemical environments. It offers higher corrosion resistance due to its molybdenum content.

Surface Coating Options

The surface coating of stainless steel enhances the aesthetic appearance and performance of the tanks:

- Polished surface: Easier to clean and provides hygiene.

- Matte surface: Ideal for outdoor use, minimizes stain formation.

The Importance of Welding Technologies

The welding process determines the leak-proofness and durability of stainless steel tanks. Modern welding technologies (e.g., laser welding) offer high precision and quality.

10. Stainless Steel Tank Production Process

Stainless steel tank production requires precision and high-tech equipment. The production stages are as follows:

Design Phase

- The size and shape suitable for the storage need are determined.

- Prototypes are created using 3D design software.

Cutting and Shaping

- Stainless steel sheets are precisely cut with laser cutting machines.

- The strength of the steel is preserved during the shaping process.

Welding and Assembly

- Superior quality welding techniques are applied to ensure leak-proofness.

- The assembly is completed by joining the parts.

Quality Control

- After production, the tanks are subjected to pressure and corrosion tests.

- A detailed inspection is carried out to ensure compliance with customer demands.

11. Stainless Steel Tank Prices

Stainless steel tank prices can vary depending on several factors. These factors include:

Pricing Based on Tank Type

- Horizontal tanks are generally produced in larger capacities, which increases their cost.

- Prismatic tanks may be more economical due to their compact designs.

Costs Based on Capacity

- Small-scale tanks (200–500 liters) are generally more affordable.

- Large-capacity tanks (5000 liters and above) are more expensive depending on the amount of steel used.

Long-Term Cost Advantages

The long life of stainless steel tanks compensates for the initial cost over time. Additionally, low maintenance costs reduce the total cost of ownership.

12. Stainless Steel Tank Maintenance and Cleaning

Regular maintenance of stainless steel tanks both extends their service life and preserves hygiene standards. Here are the things to consider in tank maintenance:

Tank Inner Surface Cleaning Methods

- Washing can be done with hot water and food-grade cleaning agents.

- Regular maintenance is essential to prevent oil and lime buildup.

Tips for Hygienic Storage

- Ventilate the tanks frequently.

- Do not use chlorine-based cleaning agents in food and water tanks.

Tank Maintenance Costs

- Stainless steel surfaces are easy to clean, which keeps maintenance costs to a minimum.

- Professional cleaning is recommended once a year.

13. Stainless Steel Tank Assembly and Installation

Stainless steel tank assembly varies depending on the tank type and application area. Here’s what to consider during installation:

Assembly Differences Between Horizontal and Vertical Models

- Horizontal tanks: Usually fixed to the ground and require a large area.

- Vertical tanks: Fixed in a vertical position and save space.

Transportation and Installation of Prismatic Tanks

- These tanks can be easily transported thanks to their modular structure.

- They can be installed quickly even in narrow spaces.

Post-Assembly Inspection Stages

- A leak test of the tanks is performed.

- Ensure that the lid and valves are working properly.

14. Relevant Regulations and Standards for Stainless Steel Tanks

Stainless steel tanks must be produced in accordance with certain standards. Here are the regulations to be considered:

Food and Industrial Use Standards

- Tanks used in the food industry must comply with HACCP and ISO 22000 standards.

- Industrial tanks are subjected to chemical resistance and pressure tests.

International Quality Certificates

- ISO 9001: Quality management system.

- EN 1.4301 (304 grade) and EN 1.4401 (316 grade) standards.

Eco-Friendly Production and Legal Regulations

- Stainless steel stands out as an environmentally friendly material.

- It is important to ensure energy efficiency during the production process.

15. Tips for Choosing the Right Stainless Steel Tank

Choosing the right stainless steel tank both protects your budget and meets your usage needs. Here’s what to consider:

Choosing a Tank Suitable for Your Needs

- Lower capacity models may be sufficient for water storage.

- 316 grade stainless steel should be preferred for industrial chemicals.

Determining the Tank Capacity

- The capacity should be determined based on the frequency of use and the amount of substance stored.

- An oversized tank can create unnecessary space and cost.

The Importance of Working with Reliable Manufacturers

- Working with certified manufacturers ensures you make a long-lasting investment.

- Prefer tanks with a manufacturer’s warranty.

Frequently Asked Questions

- How long do stainless steel tanks last?

Stainless steel tanks made from quality materials can last for 30 years or more with regular maintenance. - In which sectors are the tanks used?

They are widely used in the food, chemical, agricultural, pharmaceutical, and drinking water sectors. - What is the advantage of stainless steel prismatic tanks?

They offer more storage capacity in narrow spaces and are easy to transport. - Is a special model needed for olive oil storage?

Yes, specially designed stainless steel tanks are recommended to preserve olive oil for a long time without spoilage. - Are stainless steel tanks environmentally friendly?

Yes, stainless steel is recyclable and does not harm the environment. - Which grade of stainless steel should be used?

304 grade stainless steel should be preferred for food and water, while 316 grade should be used for chemical storage.