Stainless Flange | Durability and Applications

Stainless Flange | Durability and Applications

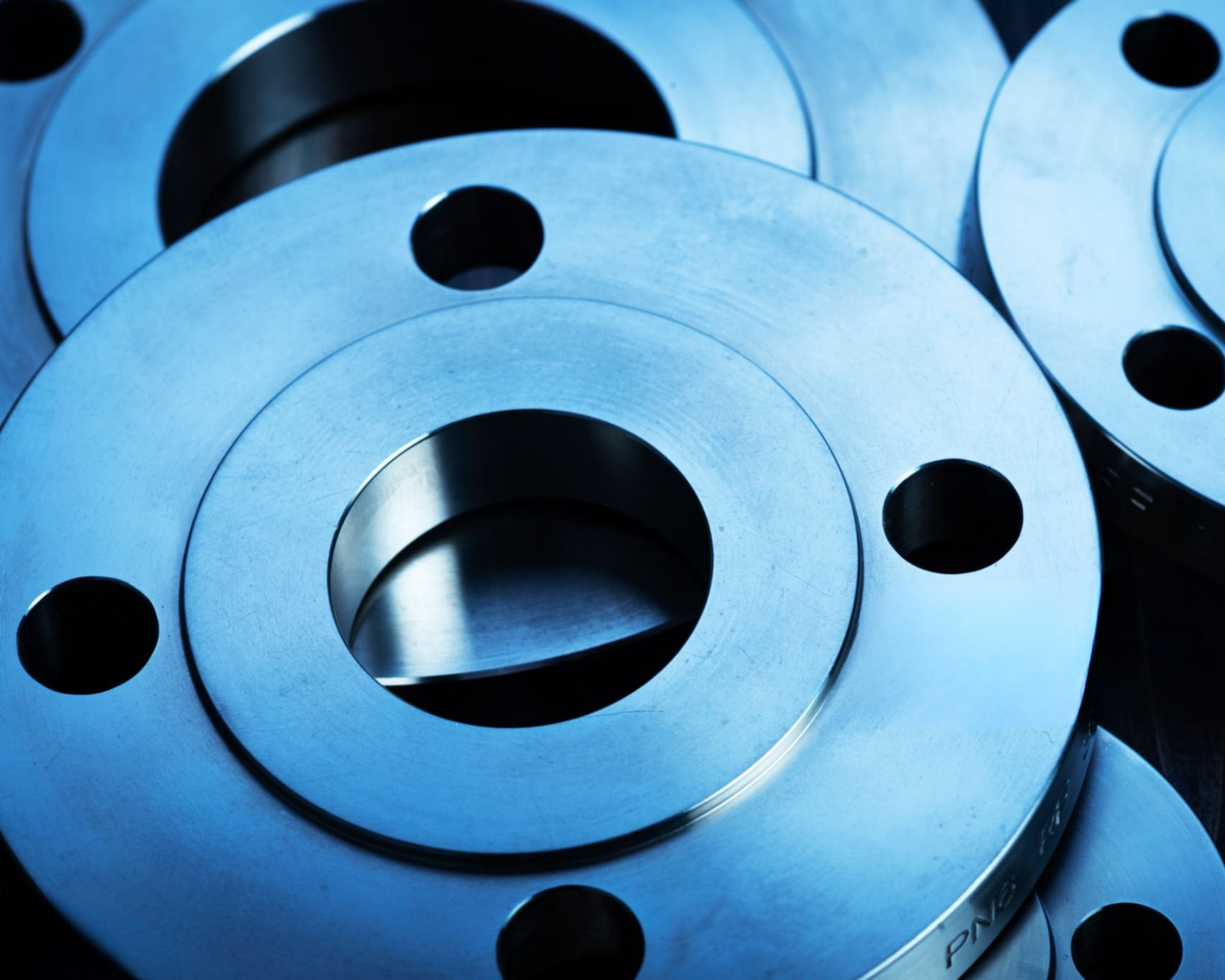

What is a Stainless Flange?

A stainless flange is a connection element made of stainless steel, used to connect pipes, valves, pumps, and other piping systems. Flanges have a structure that facilitates installation and maintenance and can be connected to piping systems using bolts or welding methods.

Types of Stainless Flanges

Stainless flanges are divided into different types according to their intended use and connection method. Here are the most common types of stainless flanges:

Welding Neck Flange

- Used in high-pressure and high-temperature systems.

- Provides excellent sealing thanks to its welding neck.

- Generally preferred in the oil and gas industry.

Slip-On Flange

- Suitable for low and medium-pressure systems.

- Easy to install and is fixed by welding.

- Common in chemical plants and water treatment systems.

Threaded Flange

- Does not require welding, installed with a threaded connection.

- Used in small-diameter and low-pressure systems.

- Especially preferred in plumbing systems.

Blind Flange

- Used to close the ends of pipes.

- Allows for the closure of the piping system during maintenance and repair operations.

- Commonly preferred in pressure tests.

Socket Weld Flange

- Used in small-diameter and high-pressure piping systems.

- A gap must be left inside during welding.

- Commonly seen in oil, gas, and water systems.

Lap Joint Flange (Loose Flange)

- Used with a backing ring to provide sealing.

- Especially preferred in stainless steel piping systems.

- Easy to install and remove.

🏭 Application Areas of Stainless Flanges

Stainless flanges have a wide range of applications. Here are the main areas of use:

- Oil and Gas Industry: Used in refineries and pipelines due to their resistance to high temperature and pressure.

- Chemical and Pharmaceutical Industry: Resistant to aggressive chemicals due to their corrosion-resistant structure.

- Food and Beverage Sector: Used in milk, water, and beverage lines thanks to their hygienic properties.

- Energy Production: Preferred in thermal and hydroelectric power plants for steam and water lines.

- Shipbuilding: Used in the maritime sector due to its resistance to saltwater.

- Water Treatment Plants: Can be used safely in clean water systems thanks to their anti-corrosion properties.

Advantages of Stainless Flanges

Stainless flanges offer many advantages compared to flanges made from other materials:

- High Durability: Stainless steel is extremely resistant to abrasion and impacts.

- Corrosion Resistance: Provides long-lasting use in humid and chemical environments.

- Easy Installation and Disassembly: Can be easily assembled and disassembled thanks to their bolted or welded connections.

- Hygienic Use: Ideal for the food and pharmaceutical industries due to its structure that does not allow bacterial growth.

- Aesthetic Appearance: Can also be used for decorative purposes thanks to its shiny and smooth surface.

Things to Consider When Choosing a Stainless Flange

It is important to consider the following factors when choosing a stainless flange:

- Pressure Rating: The flange must be suitable for the pressure level of the system in which it will be used.

- Temperature Resistance: A material resistant to high temperatures should be chosen.

- Connection Type: Welded, bolted, or threaded connection options should be determined according to the need.

- Material Quality: The appropriate type of stainless steel, such as AISI 304 or 316, should be selected.

- Size and Standards: Flanges compliant with international standards such as ANSI, DIN, and JIS should be preferred.

Frequently Asked Questions (FAQ)

What materials are stainless flanges made from?

Stainless flanges are generally produced from stainless steel types such as AISI 304, AISI 316, AISI 321. These materials are resistant to corrosion and high temperatures.

What is the lifespan of stainless flanges?

Depending on the operating conditions, it can vary between 20-50 years. With regular maintenance, they can last for many years.

How are stainless flanges cleaned?

You can use warm water, mild detergent, and a soft cloth to clean stainless flanges. Abrasive cleaning materials should be avoided.

Can stainless flanges be used in all types of piping systems?

Yes, but the flange’s pressure and temperature resistance must be compatible with the system in which it will be used. The wrong choice can lead to sealing problems.

How are stainless flange prices determined?

Prices vary according to material quality, flange type, diameter, and pressure class. Non-standard custom productions can be more expensive.

What is the difference between a stainless steel flange and a carbon steel flange?

Stainless flanges are corrosion-resistant and can be used in hygienic environments. Carbon steel flanges, on the other hand, are more cost-effective but are not protected against rust.

Stainless flanges are connection elements preferred in many industries due to their robustness, long service life, and superior resistance to corrosion. Choosing the right material and flange type ensures the safe and efficient operation of the system. If you are considering purchasing stainless flanges, you should make your selection by considering the appropriate pressure class and material quality for your needs.

For Detailed Information Click Here.