Stainless Pipe | Durability and Applications

Stainless Pipe | Durability and Applications

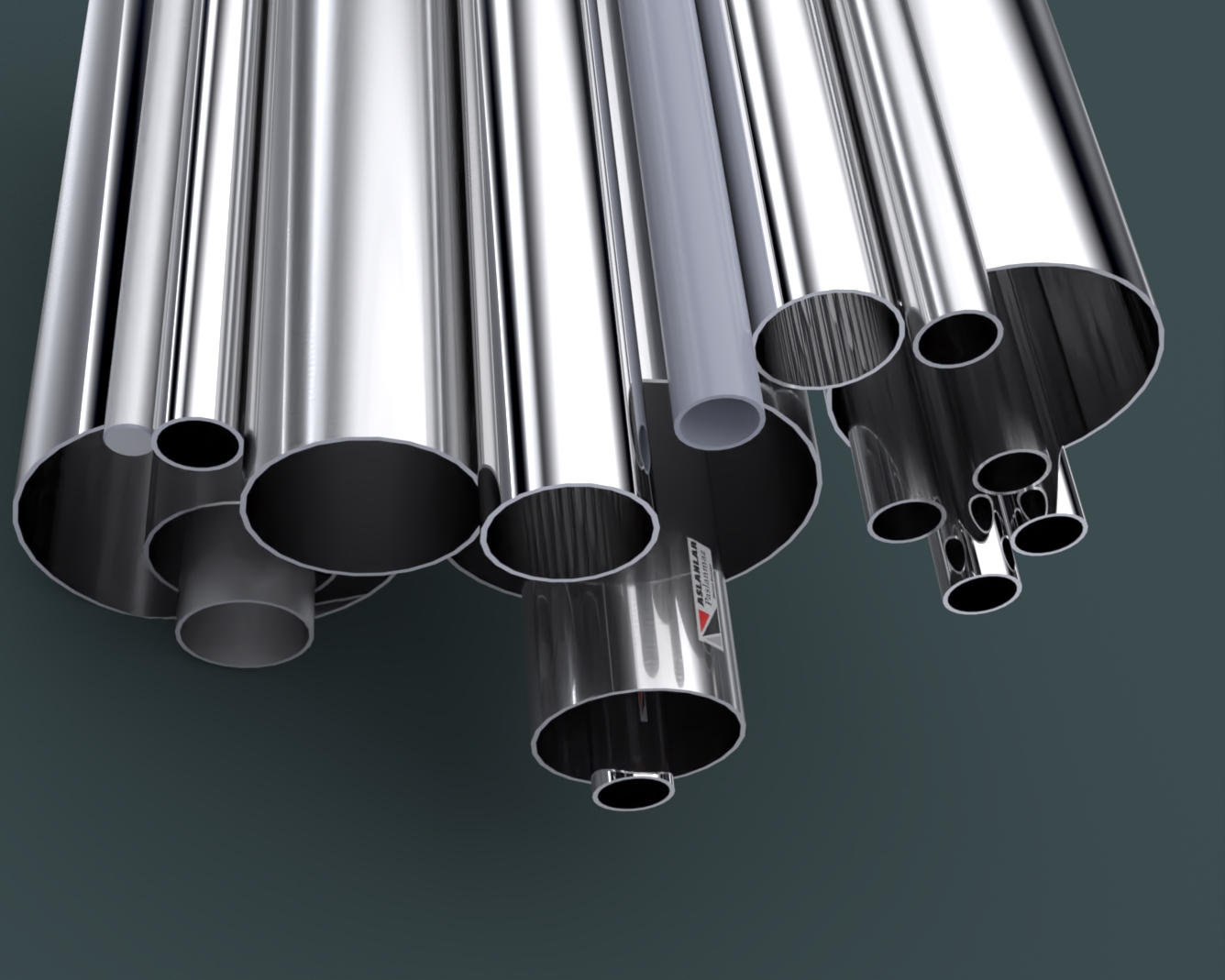

- What is a Stainless Steel Pipe?

A stainless steel pipe is a type of steel pipe resistant to rust, containing iron, chromium, nickel, and other alloys. It is mostly preferred for its corrosion resistance, long-lasting structure, and aesthetic appearance.

- Types and Grades of Stainless Steel

Stainless steel pipes are produced in different types according to their components:

- 304 Stainless Steel: It is the most commonly used type. It is used in the chemical, food, and decoration industries.

- 316 Stainless Steel: It has high corrosion resistance and is especially used in the maritime, chemical, and medical industries.

- 321 Stainless Steel: It is resistant to high temperatures and is particularly preferred in heating systems.

- Stainless Steel Pipe Production Processes

Stainless steel pipes are produced by two main manufacturing methods:

- Seamless Stainless Steel Pipes: Produced by the continuous casting method, they are resistant to pressure.

- Welded Stainless Steel Pipes: Produced by welding steel plates, they are more cost-effective.

- Chemical and Mechanical Properties of Stainless Steel Pipes

- Corrosion Resistance: It is stainless due to its high chromium and nickel content.

- Mechanical Strength: It is resistant to high temperatures and pressure.

- Lightness and Durability: It is lighter and has a longer lifespan compared to carbon steel.

- Applications of Stainless Steel Pipes

- Construction Sector: Bridges, buildings, railings

- Food Industry: Food processing machinery, drinking water lines

- Automotive Industry: Exhaust systems, chassis structures

- Chemical Industry: Pipes resistant to acids and chemicals

- Health and Medical Field: Surgical equipment, sterile lines

- Energy and Oil-Gas Sector: High-pressure and heat-resistant pipes

- Advantages of Stainless Steel Pipes

✔ Stainless and Corrosion Resistance

✔ High Strength and Durability

✔ Aesthetic and Modern Appearance

✔ Low Maintenance Cost

✔ Hygienic and Suitable for the Food Industry

- Types of Stainless Steel Pipes

- Round Stainless Steel Pipes

- Rectangular Stainless Steel Pipes

- Square Stainless Steel Pipes

- Spiral Stainless Steel Pipes

- Stainless Steel Pipe Standards and Quality Certificates

- ASTM A312 / A213 / A269

- EN 10217 / 10296

- DIN 17456 / 17458

- Factors Affecting Stainless Steel Pipe Prices

- Raw Material Prices

- Production Method (Seamless or Welded)

- Pipe Diameter and Wall Thickness

- Market Demand and Exchange Rates

Frequently Asked Questions (FAQ)

- Is stainless steel pipe truly stainless?

Yes, thanks to its high chromium content, an oxide layer forms on the surface that prevents rusting. However, excessive chemical contact or improper maintenance can accelerate rusting.

- Where are stainless steel pipes used?

They have a wide range of applications in the construction, food, automotive, chemical, energy, and medical sectors.

- How should a stainless steel pipe be cleaned?

Regular maintenance should be performed with non-detergent stainless steel cleaners. Abrasive sponges should be avoided to prevent scratching.

- Is a welded or seamless stainless steel pipe better?

Seamless pipes are more resistant to pressure and high temperatures, but welded pipes are more economical.

- What is the average lifespan of stainless steel pipes?

Depending on the place of use and maintenance, it can vary between 20-50 years.

- How is the price of stainless steel pipes determined?

Prices vary according to the type of steel used, production method, pipe thickness, and exchange rates.

Stainless steel pipes are indispensable in many industries due to their durability and versatile use. To choose a quality stainless steel pipe, you should pay attention to certifications and the reliability of the manufacturer.

To determine the most suitable stainless steel pipe solution for you, you can contact reliable manufacturers for detailed information and a price quote.