What are Stainless Fittings?

Definition and General Application Areas of Fittings

The term Stainless Fittings Materials, “Fittings,” refers to the connection parts that enable pipes or hoses to be joined in various ways. Thanks to parts like elbows, tees, and reducers, the direction, diameter, or connection type of pipelines can be changed.

These parts are particularly used in the following areas:

- Water and gas pipelines

- Food production facilities

- Petrochemical plants

- Medical gas systems

- Fire suppression systems

Advantages of Stainless Fittings Materials

Stainless steel is one of the most preferred materials in fittings production due to its high resistance to corrosion. The main reasons for this are:

- High corrosion resistance: It is resistant to environmental factors such as acid, base, and moisture.

- Long-lasting structure: It can provide trouble-free service for 20-50 years.

- Hygienic: Ideal for the food and pharmaceutical industries.

- Aesthetic appearance: Its shiny surface is suitable for modern installations.

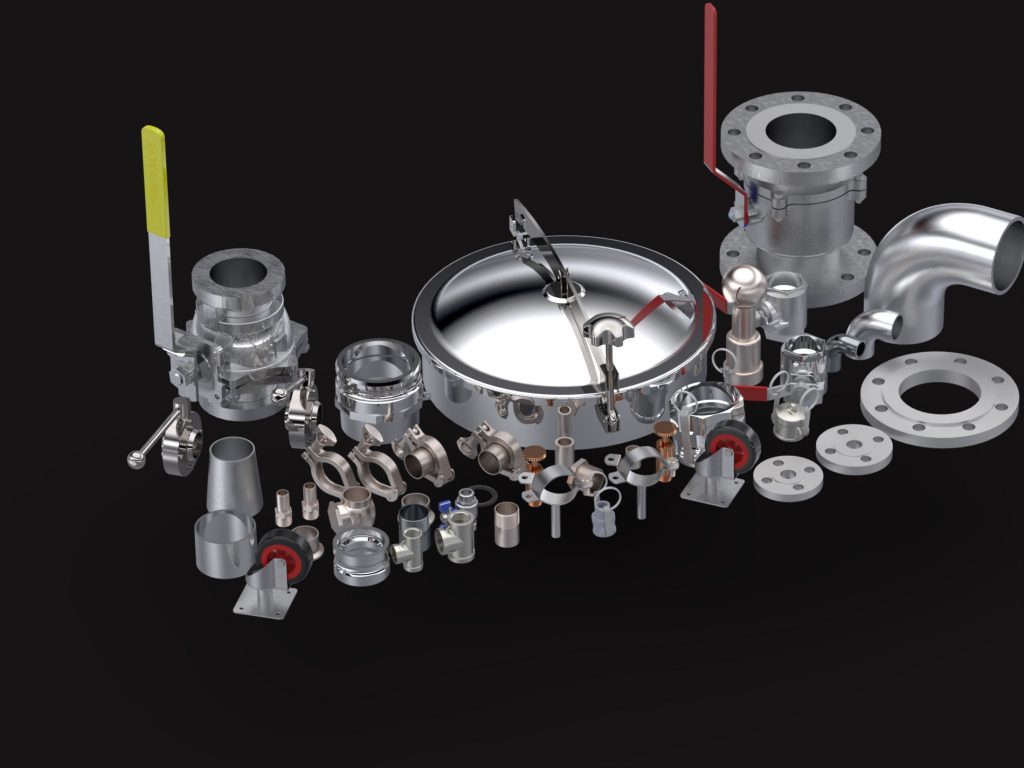

Types of Stainless Fittings

Elbows

These parts, used to change the direction of a pipeline, are generally produced at 45°, 90°, and 180° angles.

Tees

Provides a three-way connection. It is used to direct the same fluid in different directions or to join different lines.

Reducers

Used to connect pipes of different diameters. Concentric and eccentric types are available.

Caps and Plugs

Allows for the closing of system ends. Ideal for increasing sealing and stopping flow during maintenance operations.

Nipples and Unions

Used to transition between two connection points. Threaded or welded types are available.

Stainless Steel Grades Used

Different grades of steel are preferred in the production of stainless fittings. These grades are determined according to the area of use and environmental conditions.

304 Grade

It is the most commonly used type of stainless steel. It stands out with the following features:

- Provides high corrosion resistance.

- Widely used in the food and beverage industry.

- It is an economical and efficient solution in salt-free environments.

316 Grade

It is an alloy developed for more aggressive environmental conditions. Its features are:

- It is more resistant to acid and salt water thanks to the Molybdenum (Mo) element.

- Preferred in the marine and chemical sectors.

- It is long-lasting and hygienic.

Comparisons of 316L and 321 Grades

- 316L contains lower carbon. This feature prevents post-weld cracking.

- 321 is titanium-stabilized and provides stability at high temperatures.

- Both grades offer high performance, but the choice should be made according to industry needs.

Things to Consider When Choosing Fittings

Choosing the right stainless fittings ensures the efficient and long-lasting operation of the system.

Pressure Resistance

The fitting material must be suitable for the system’s operating pressure. An incorrect choice:

- Can create a risk of explosion

- Can reduce system efficiency

Corrosion Resistance

The choice should be made by considering environmental conditions, chemical substances, and liquids. Grade 316 is recommended for environments containing chemicals.

Temperature Tolerance

Some stainless fitting materials can lose their strength at high temperatures. Materials resistant to high heat should be used.

Connection Type Compatibility

The choice should be made considering connection types such as threaded, welded, or flanged. Otherwise, incompatibility may occur.

Sectoral Application Areas

Food Industry

Due to their hygienic properties, stainless fittings are used in milk, fruit juice, drinking water, and other food processes.

Chemical Industry

Thanks to its chemical resistance, it offers long-lasting performance in corrosive environments. It is resistant to acid, base, and salt solutions.

Petrochemicals and Energy

Its resistance to high temperature and pressure increases its use in these sectors. It is indispensable in gas transportation systems.

Water Treatment Systems

With its resistance to corrosion, it is safely preferred in treatment plants. It is also environmentally friendly and has low maintenance costs.

Installation and Application Methods

Welded Connections

Preferred in high-pressure systems. It is the safest method in terms of sealing.

Threaded Connections

Used in small-diameter systems and low-pressure applications. They can be easily assembled and disassembled.

Flanged Systems

Used in medium and large-diameter pipe systems. It provides easy maintenance and replacement.

Advantages of Stainless Fittings Materials

Long Life

Stainless steel is highly resistant to oxidation and decay. This extends the life of the system.

Hygienic Properties

Thanks to its non-porous surface that does not harbor germs, it is indispensable, especially in the food and health sectors.

Easy Maintenance and Cleaning

It can be cleaned quickly thanks to its smooth surface. No dirt or residue remains on the surface after cleaning.

Disadvantages and Challenges

High Cost

The initial investment cost is high. However, in the long run, the maintenance cost is low, making it more economical.

Welding Difficulty

Welding stainless steel requires expertise. The weld zone must be well protected.

Surface Treatment Requirement

In some applications, special surface treatments (e.g., polishing) may be required.

Differences Between Stainless Fittings and Carbon Steel

|

Feature |

Stainless Steel |

Carbon Steel |

|

Corrosion Resistance |

Very High |

Low |

|

Durability |

Long-lasting |

Medium |

|

Hygiene |

High |

Low |

|

Price |

High |

Low |

|

Application Area |

Food, chemical, marine |

Construction, heating |

International Standards and Certifications

ASTM, DIN, and ISO Standards

These three standards are the basis for the production of stainless fittings. They are accepted as references in quality control processes.

Food and Drug Compliance Documents

Products approved for food safety are used with documents such as FDA, 3A, and EHEDG.

Suppliers and Pricing Strategies

Domestic vs. Imported Products

Both domestically produced and imported stainless fittings are available. Both options have their own advantages:

- Domestic products: Offer faster supply and a price advantage.

- Imported products: Generally have higher quality and international certifications.

Factors Affecting Prices

Some basic factors that determine the prices of stainless fittings are:

- Steel grade used (304, 316, etc.)

- Product type and size

- Production method (forged, welded, etc.)

- Order quantity and custom production requests

- Exchange rate differences and shipping costs

Points to Consider When Choosing a Supplier

- The product’s quality certificates and compliance with standards

- After-sales technical support

- Warranty and return policies

- Fast delivery time and stock availability

Maintenance and Service Life of Stainless Fittings

Stainless fittings can be used for decades with proper maintenance.

Cleaning Recommendations

- Should be cleaned regularly with warm water and neutral detergents.

- Abrasive chemicals should be avoided.

- Moisture accumulation should be prevented by drying after cleaning.

Corrosion Prevention Methods

- The pH balance of the fluids used in the system should be considered.

- Attention should be paid to scratches and impacts on the surface during installation.

- Passivation processes can be applied.

Periodic Inspections

- Pipelines and fittings should be visually inspected regularly

- The tightness of connection points should be checked

- Part replacement should be done if necessary

Sustainability and Recycling

Stainless Steel Recycling

Stainless steel is a 100% recyclable material. When its service life ends:

- It can be collected as scrap

- It can be reused in new steel production

- It does not harm nature

Environmental Impacts

- Prevents resource waste due to its long life

- Does not leak chemical substances

- Is effective in reducing the carbon footprint

Conclusion and Expert Advice

Which Fitting Material is Right for You?

Choosing the right fitting according to your system’s needs is critical for both efficiency and longevity. If high temperature, pressure, or chemical resistance is required, grade 316 products should be preferred. For more standard applications, grade 304 is suitable and economical.

Long-lasting Systems with Quality Choices

Making quality-oriented, not price-oriented, choices will make you profitable in the long run. Certified products from reliable suppliers will make your system safer and more efficient.

Frequently Asked Questions (FAQ)

Under proper installation and maintenance conditions, stainless fittings can operate without problems for 20 to 50 years.

Grade 316 stainless steel is more durable, especially in chemical and marine environments, thanks to its molybdenum content.

Some types of fittings (like welded ones) require special equipment and expertise. For threaded parts, basic hand tools are generally sufficient.

They are used in a very wide range, especially in the food, chemical, petrochemical, energy, pharmaceutical, and marine industries.

This depends on the application. Threaded fittings are sufficient for low-pressure and temporary systems. However, welded fittings are safer for high-pressure permanent systems.

Prices vary according to the steel grade, product type, diameter size, order quantity, production method, and the supplier’s policies.