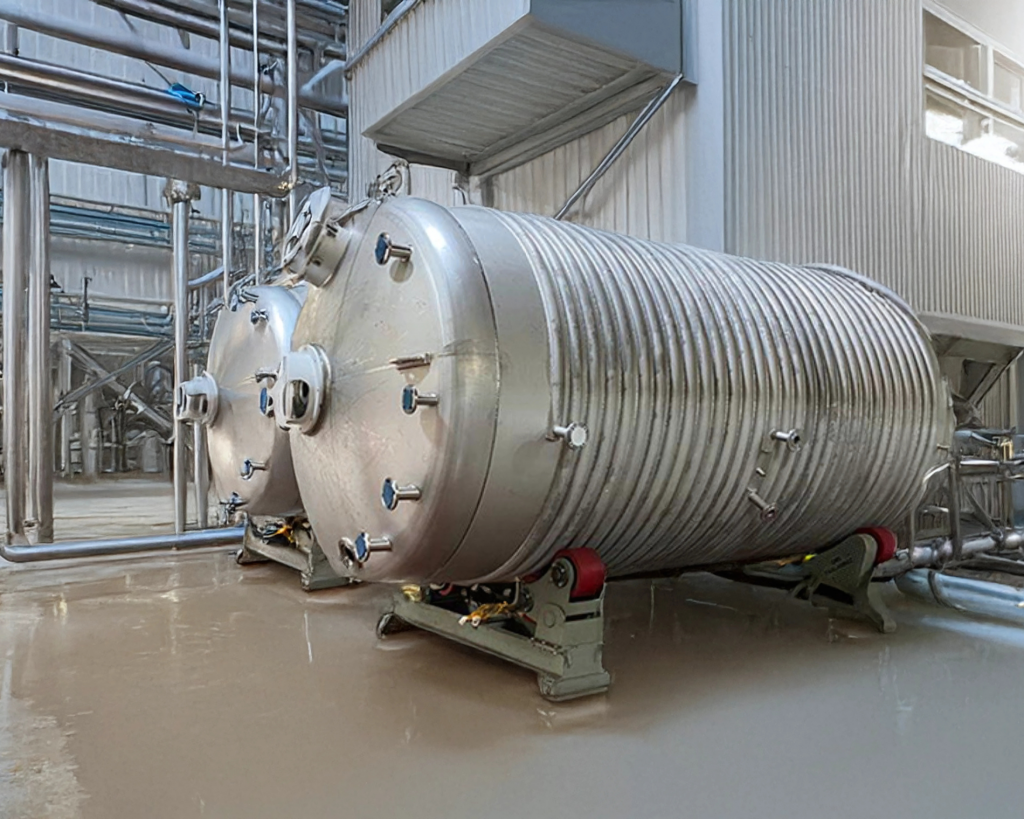

What is a Coil Mixer?

A coil mixer is a special type of mixer that contains coiled tubes called serpentines. By passing a hot or cold fluid through these tubes, it is possible to keep the temperature of the processed material under control. It is particularly used in processes requiring heat transfer and provides significant advantages in terms of energy efficiency.

Operating Principle of Coil Mixers

Heat Transfer Mechanism

Coil mixers enable the transfer of fluids used for heating or cooling purposes. This process works as follows:

- Hot or cold fluid is supplied to the serpentine tubes.

- Heat is transferred to the mixed substance through the surface of the tubes.

- This allows the mixture temperature to reach the desired level.

For example, a coil mixer can be used in a food production facility to keep chocolate in a liquid state.

Fluid Movement and Mixing Process

In coil mixers, the movement of the fluid creates a turbulent flow, ensuring a homogeneous mixture. As a result:

- Heat is distributed evenly.

- Product quality increases.

- Unwanted temperature differences are eliminated.

Types of Coil Mixers

- Single-Pass Systems: Heat transfer is completed in a single pass, operating faster and more efficiently.

- Multi-Pass Systems: Suitable for more precise heating and cooling processes.

- Steam and Water-Heated Models: These are systems that operate with steam or hot water, providing energy savings.

Applications of Coil Mixers

Chemical and Petrochemical Industry

They are preferred for carrying out chemical reactions at controlled temperatures. They are particularly used in reactors, solvent mixtures, and polymer production.

Food and Beverage Production

Used in the dairy, chocolate, confectionery, and beverage sectors to maintain a homogeneous consistency and the desired temperature.

Pharmaceutical Industry

In pharmaceutical production, they ensure the stabilization and controlled mixing of active ingredients.

Energy and Waste Management

Used in biodiesel production and wastewater treatment processes, providing efficient energy management.

Advantages of Coil Mixers

- Provides high heat transfer efficiency.

- Reduces costs through energy savings.

- Offers durable and long-lasting use.

- Manufactured from materials with high chemical and thermal resistance.

Things to Consider When Choosing a Coil Mixer

- Material Selection: Corrosion-resistant materials such as stainless steel should be preferred.

- Capacity and Pressure Ratings: Models with the correct flow rate and pressure for the application should be selected.

- Ease of Cleaning and Maintenance: Easily cleanable models are important in sectors requiring hygiene.

Maintenance and Cleaning of Coil Mixers

- Should be cleaned regularly with acidic solutions to prevent scaling and blockages.

- Pipes and connection points should be checked at regular intervals.

- Sterilization processes are particularly important in the food and pharmaceutical sectors.

Differences Between Coil Mixers and Traditional Mixers

|

Feature |

Coil Mixer |

Traditional Mixer |

|

Heat Transfer |

High efficiency |

Low efficiency |

|

Homogeneous Mixture |

Better |

Lower |

|

Energy Savings |

High |

Medium |

|

Application Area |

Wide |

More limited |

Coil mixers are modern equipment that offer high efficiency, energy savings, and long-lasting use. They hold an important place in every industrial process requiring homogeneous mixing and temperature control.

Maximum performance can be achieved with the right selection and regular maintenance.

Frequently Asked Questions (FAQ)

They are widely used in the chemical, food, pharmaceutical, and energy sectors.

Periodic chemical cleaning is recommended to prevent the formation of scale and sediment.

Yes, since heat transfer is efficient, it minimizes energy consumption.