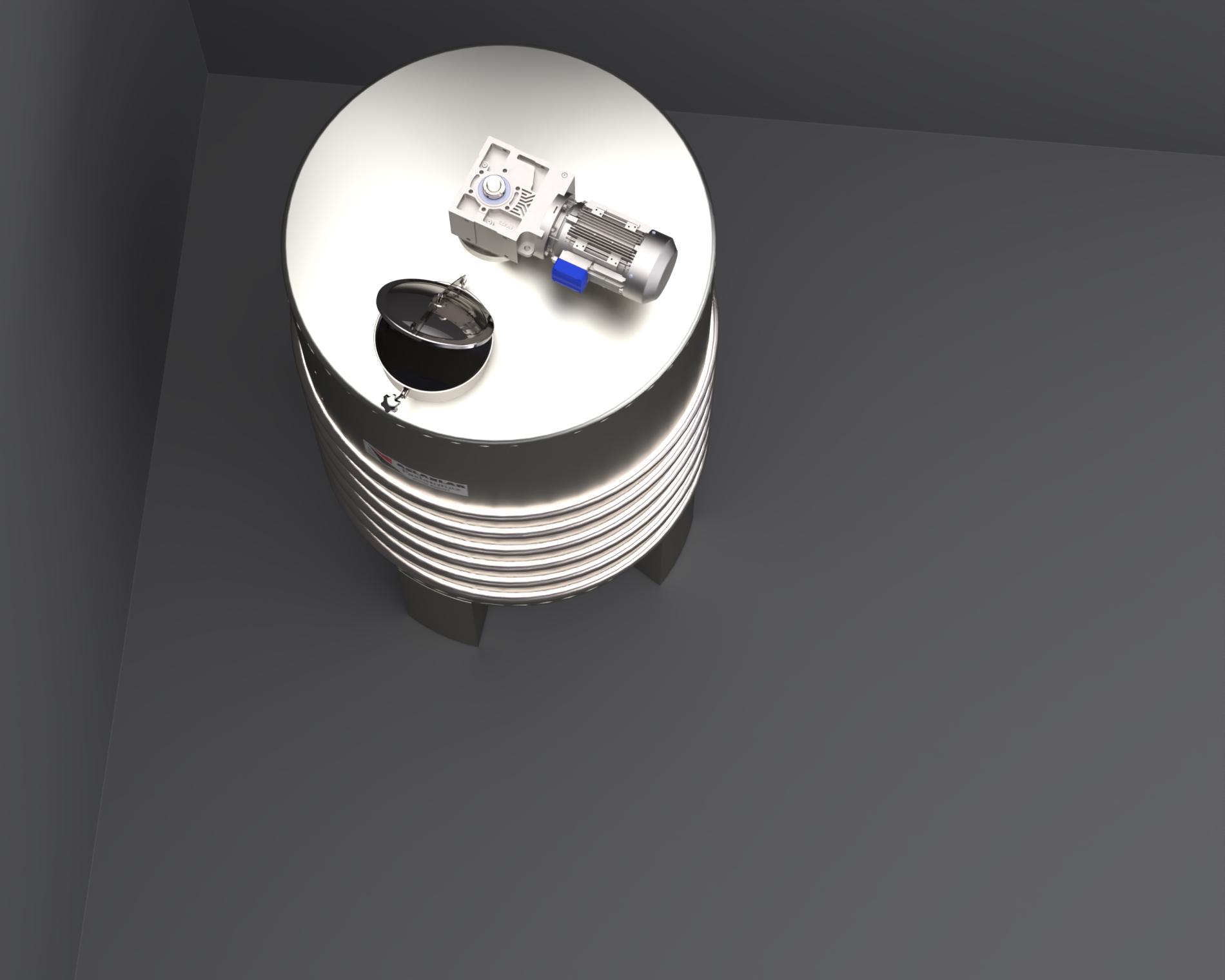

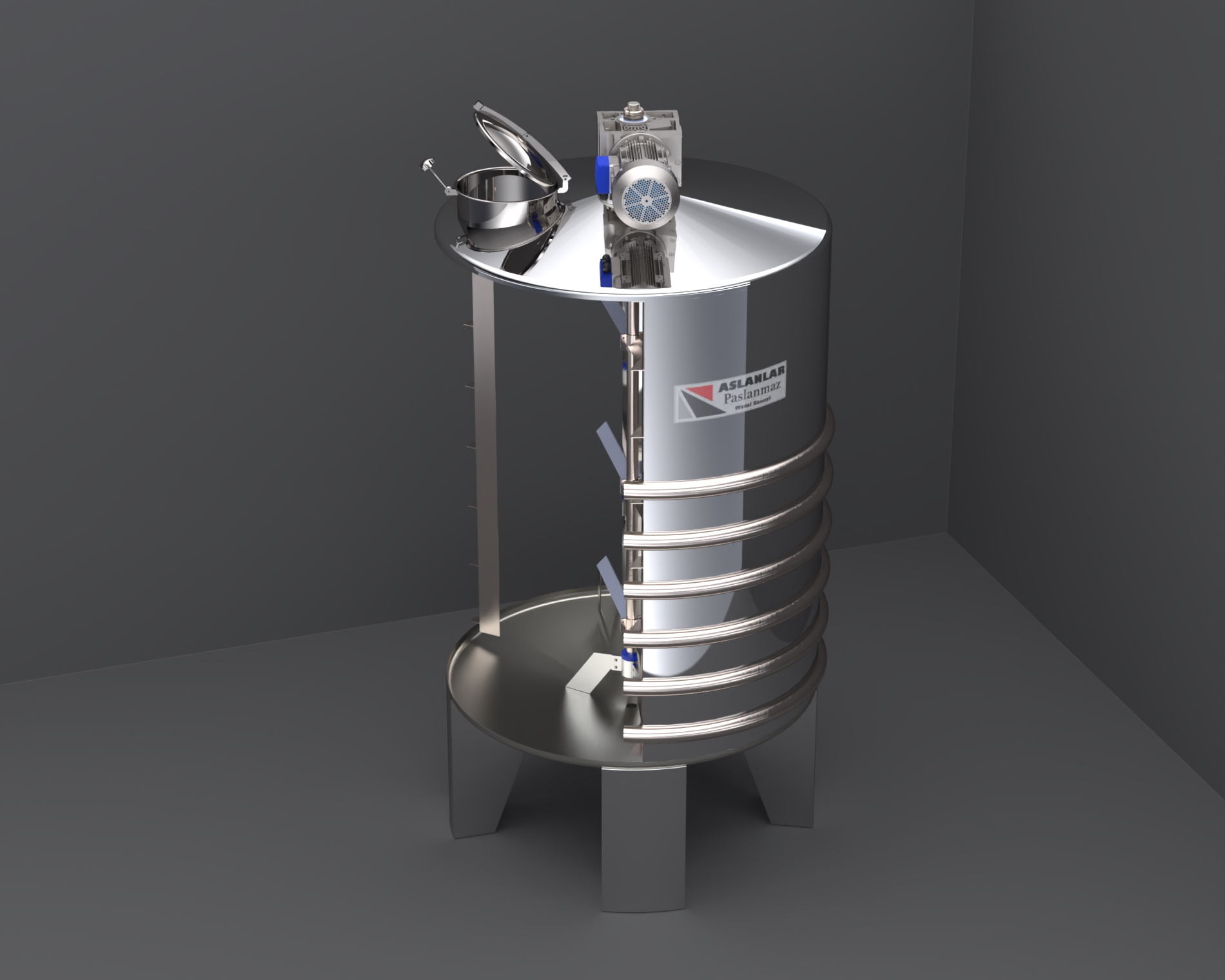

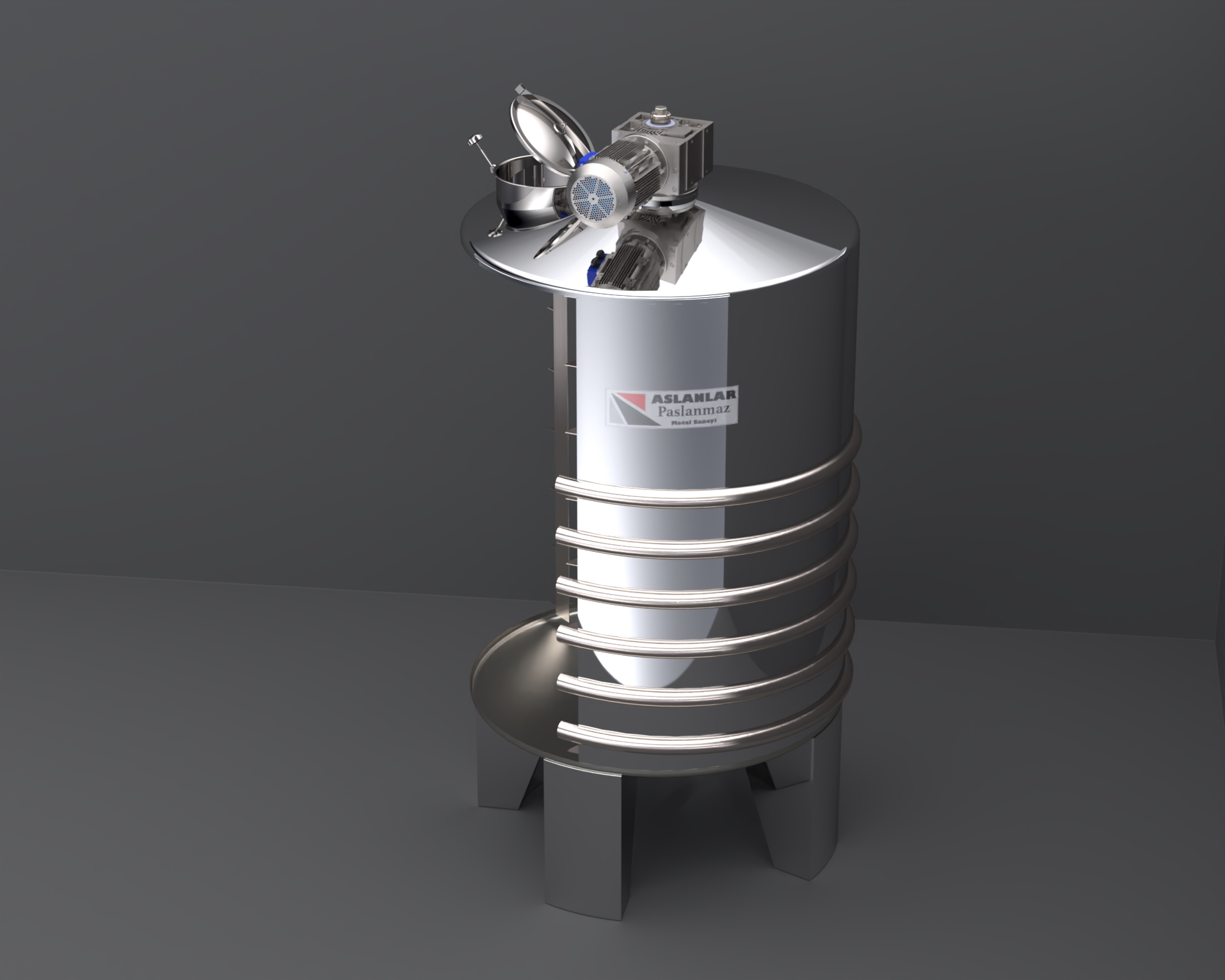

Stainless Mixer

In the Chemical, Pharmaceutical, and Food Industries, the mixing process is at the heart of many productions. By definition, mixing is the process of combining different materials to produce a homogeneous product. For this reason, stainless mixers and Stainless Reactors, made from stainless metal, are used in many fields such as the food and chemical sectors. The mixing process is of vital importance in the Polymer, Glass, Ceramics, Building Materials, Petroleum, Energy Industries, and Industrial Waste Treatment Systems. Especially Stainless Reactors offer reliable and long-lasting solutions in these sectors with their durability and chemical resistance properties.

About the Product

Mixing is a critical process because the quality and properties of the final product are derived from the resulting mixture. Faulty mixing results in a heterogeneous product that does not have the desired consistency in terms of desired properties such as chemical composition, color, texture, odor, reactivity, and particle size. Therefore, the quality of the product is important. In particular, the use of stainless reactors offers a great advantage in ensuring the homogeneity of the mixture and increasing product quality.

It is used as a liquid mixer in many areas such as detergents, chemical liquids, shampoo, cream, cosmetics, and food products.

It is produced from stainless steel sheet..

The motors of the stainless mixers are included in the prices.

A stainless reactor is a closed vessel made of stainless steel where chemical reactions take place in a controlled manner. It is used in various industries such as chemistry, food, and pharmaceuticals that require high corrosion resistance, durability, and hygiene.

Corrosion Resistance: Stainless steel shows high resistance to chemical substances.

Durability: It has high mechanical strength and is long-lasting.

Hygiene: It is easy to clean and prevents bacterial growth.

Heat Resistance: It is resistant to high temperatures.

Aesthetics: Stainless steel has a shiny and clean appearance.

Chemical Industry: Chemical reactions, mixing, and storage.

Food and Beverage Industry: Fermentation, mixing, and storage.

Pharmaceutical Industry: Sterile production processes and storage.

Petrochemicals: Crude oil processing and storage of products.

Water Treatment: Chemical treatment processes.

Product Details

Although mixing and blending are often used interchangeably, they are technically somewhat different. Blending is the process of gathering materials together. The product produced in universal reactors is taken to a blender and blended to be ready for shipment. In terms of the phase of the substance, blending is a solid process. Solid mixing or mixing bulky solids with a small amount of liquid is performed. However, blending is a much gentler process compared to mixing. Therefore, mixing technology is more closely related to liquids. In liquids, gas-liquids, and viscous substances, productivity and product quality increase thanks to gains in mixing performance and efficiency. The stainless reactors used in these processes are preferred for their material durability and hygiene, ensuring that mixing operations are carried out effectively and safely. In particular, modern stainless reactors designs contribute to raising quality standards in production processes by ensuring the homogeneous mixing of different phases.

Click for Detailed Stainless Reactors.