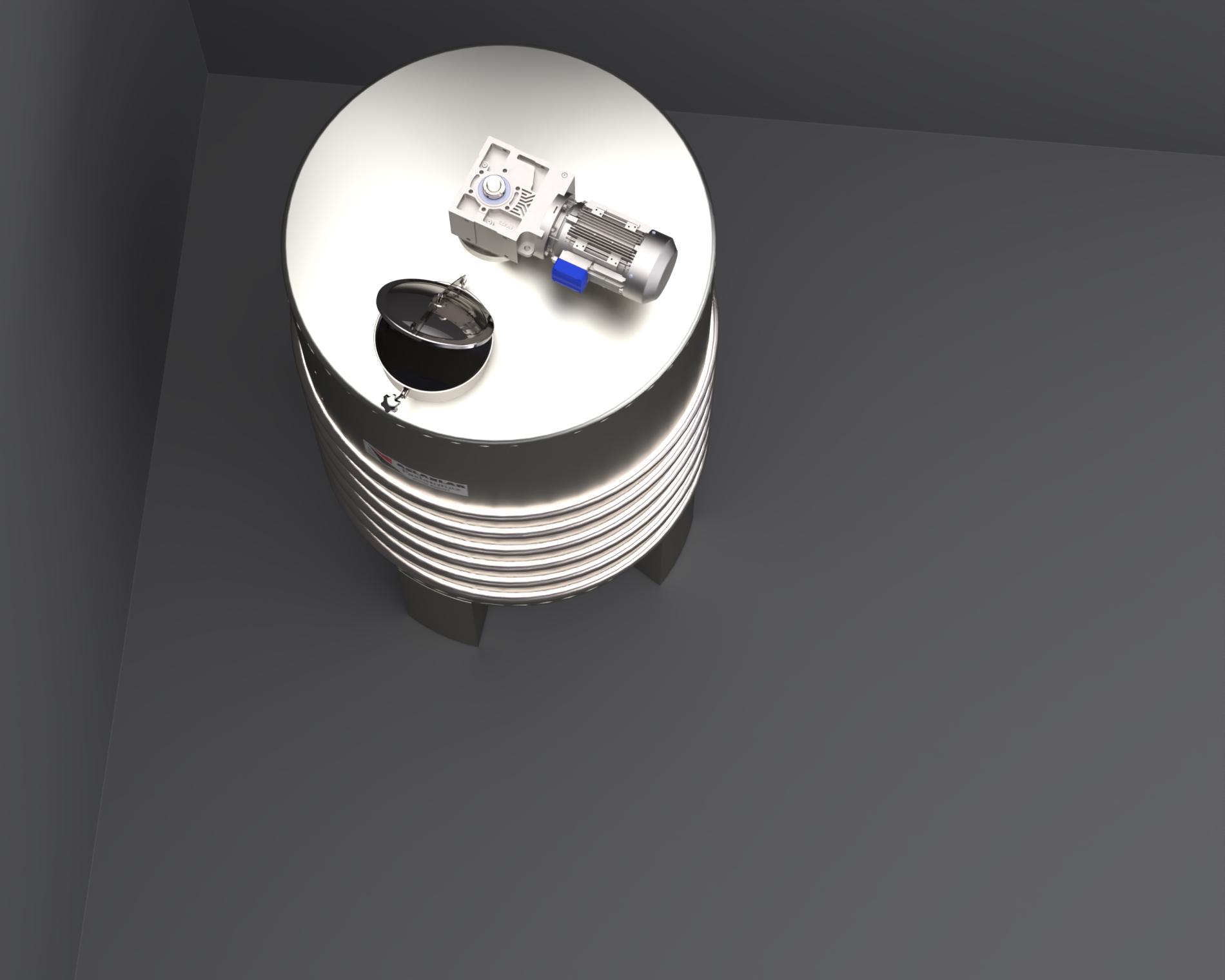

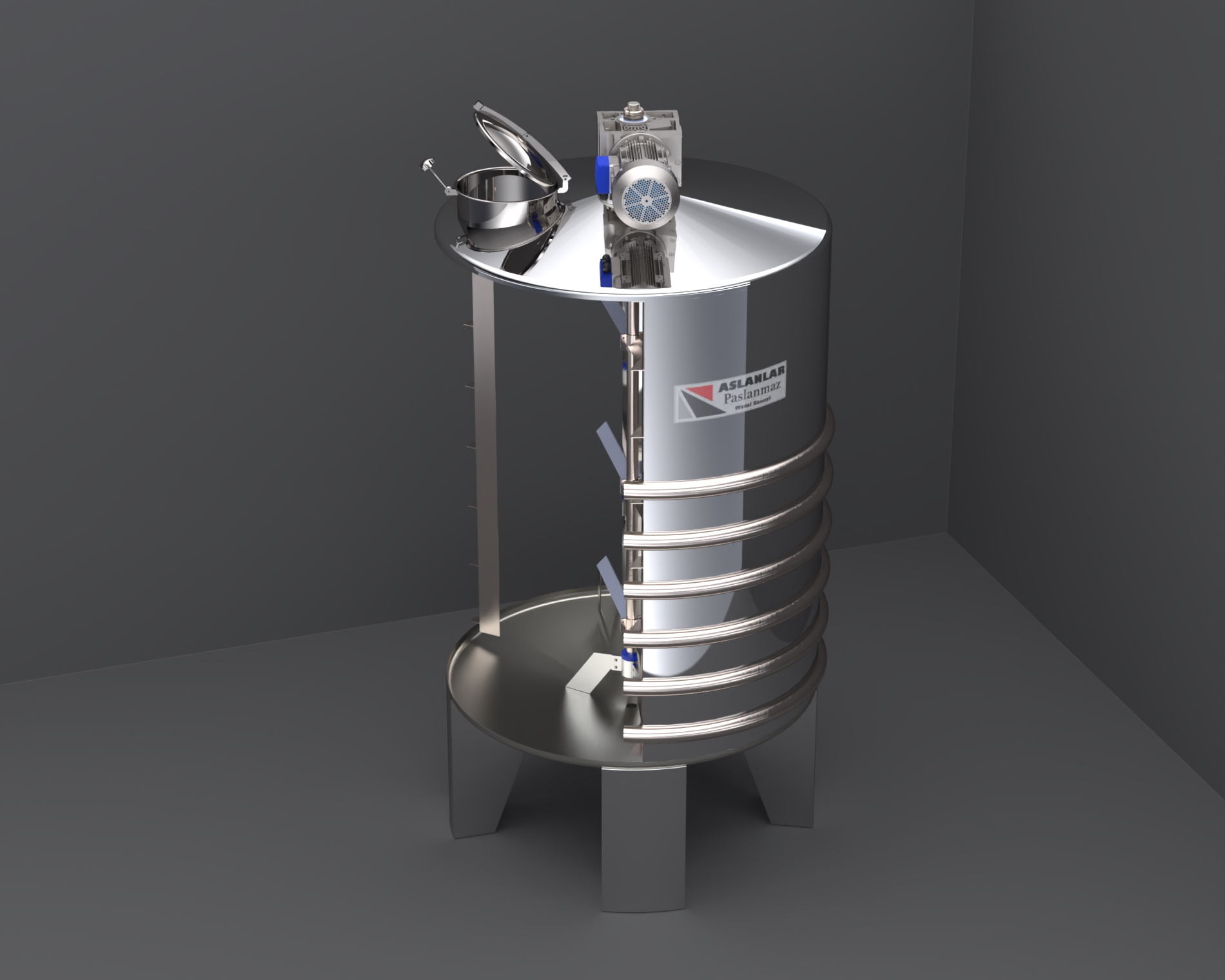

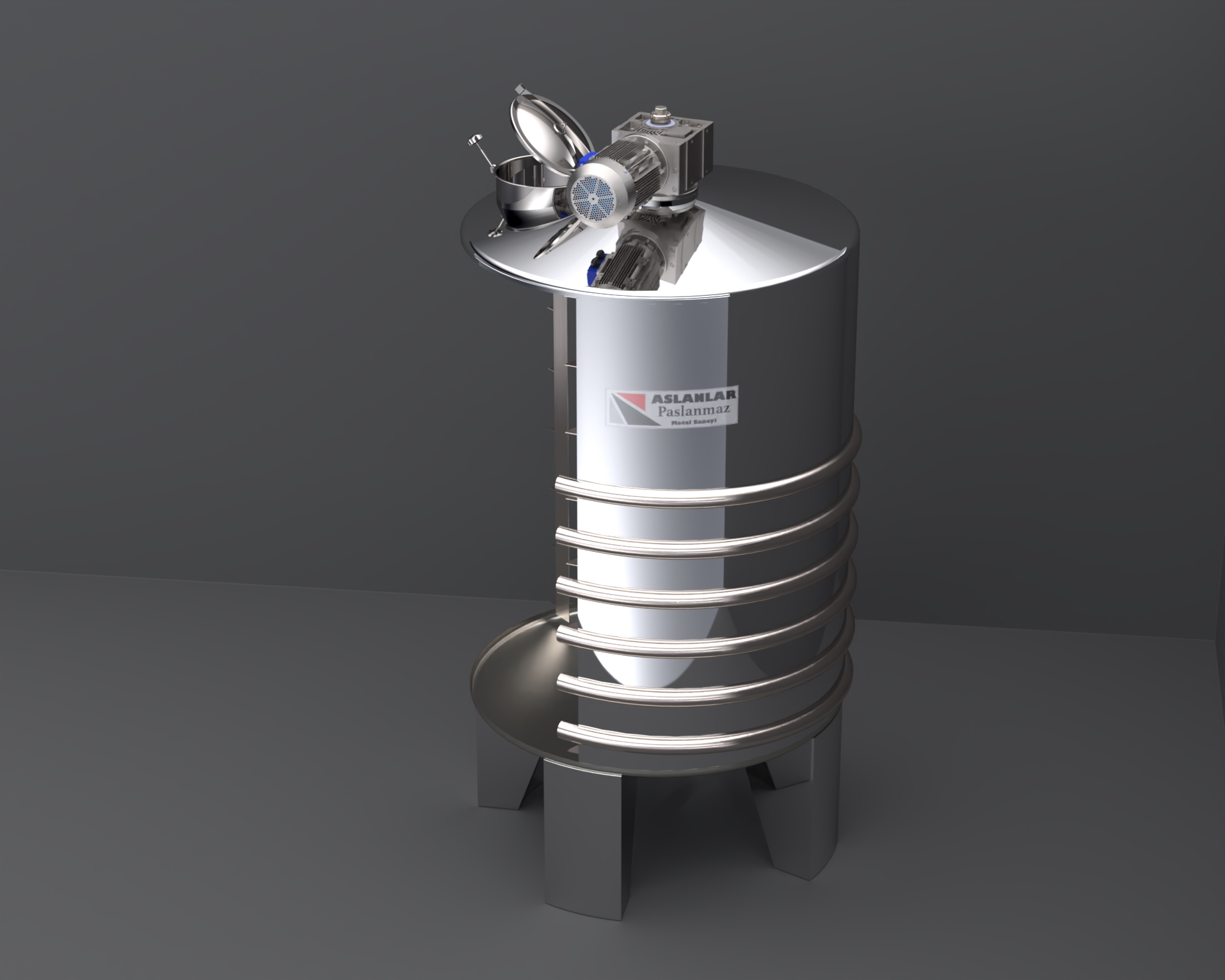

Stainless Reactor

A stainless reactor is a closed cabinet in which a chemical reaction takes place. These reactors are usually made of stainless steel because stainless steel is an ideal material for chemical reactions as it is corrosion resistant and hygienic. Stainless reactors are used in the chemical, food, pharmaceutical, paint, cosmetics and other industrial sectors. Chemicals are produced or processed in these reactors.

Mixing is at the heart of many productions in the Chemical, Pharmaceutical and Food Industries. By definition, mixing is the process of combining different materials to produce a homogeneous product. For this reason, stainless mixers made of stainless metal are used in many areas such as the food and chemical industry. Mixing is vital in Polymer, Glass, Ceramics, Building Materials, Petroleum, Energy Industries and Industrial Waste Treatment Systems.

About product

Mixing is a critical operation. Because the quality and properties of the final product come from the mixture obtained. Incorrect mixing results occur in a heterogeneous product that does not have the desired consistency in terms of desired properties such as chemical component, color, texture, odour, reactivity and particle size.

Although Blending and Blending are often used as alternatives to each other, they are technically partially different. Blending is the process of putting substances together. Before the product produced in the reactors is ready for shipment, it is taken to the Blender and blended and made ready for shipment. In terms of the phase of matter, blending is the solid process. Bulk solids are mixed with solid mixing or a small amount of liquid. However, blending is a fairly light process compared to blending. That’s why Mixing technology is more closely related to liquid. Liquid, gaseous, liquid and viscous substances also increase productivity and product quality thanks to gains in performance and efficiency of mixing.

It is used as a liquid mixer in many areas such as detergent, chemical liquids, shampoo, cream, cosmetics and food products.

It is produced from stainless steel sheet and stainless steel materials. Stainless reactors are generally used with many equipments: for example mixers, heaters, coolers, pressure sensors, thermometers, control panel or automation system. These equipment are used to carry out or control reactions inside reactors.

The motors used in stainless reactors are included in the prices.

Product Details

A stainless reactor is a closed cabinet in which a chemical reaction takes place. These reactors are usually made of stainless steel because stainless steel is an ideal material for chemical reactions as it is corrosion resistant and hygienic. Stainless reactors are used in the chemical, food, pharmaceutical, paint, cosmetics and other industrial sectors. Chemical substances are produced or processed in these reactors.

Stainless reactors are generally divided into two types: vertical and horizontal. Vertical reactors are used for small volume and less complex reactions, while horizontal reactors are used for larger volume and more complex reactions.

Stainless reactors are often used with many equipment: for example, mixers, heaters, chillers, pressure sensors, thermometers, control panel or automation system. These equipment are used to carry out or control reactions inside reactors.