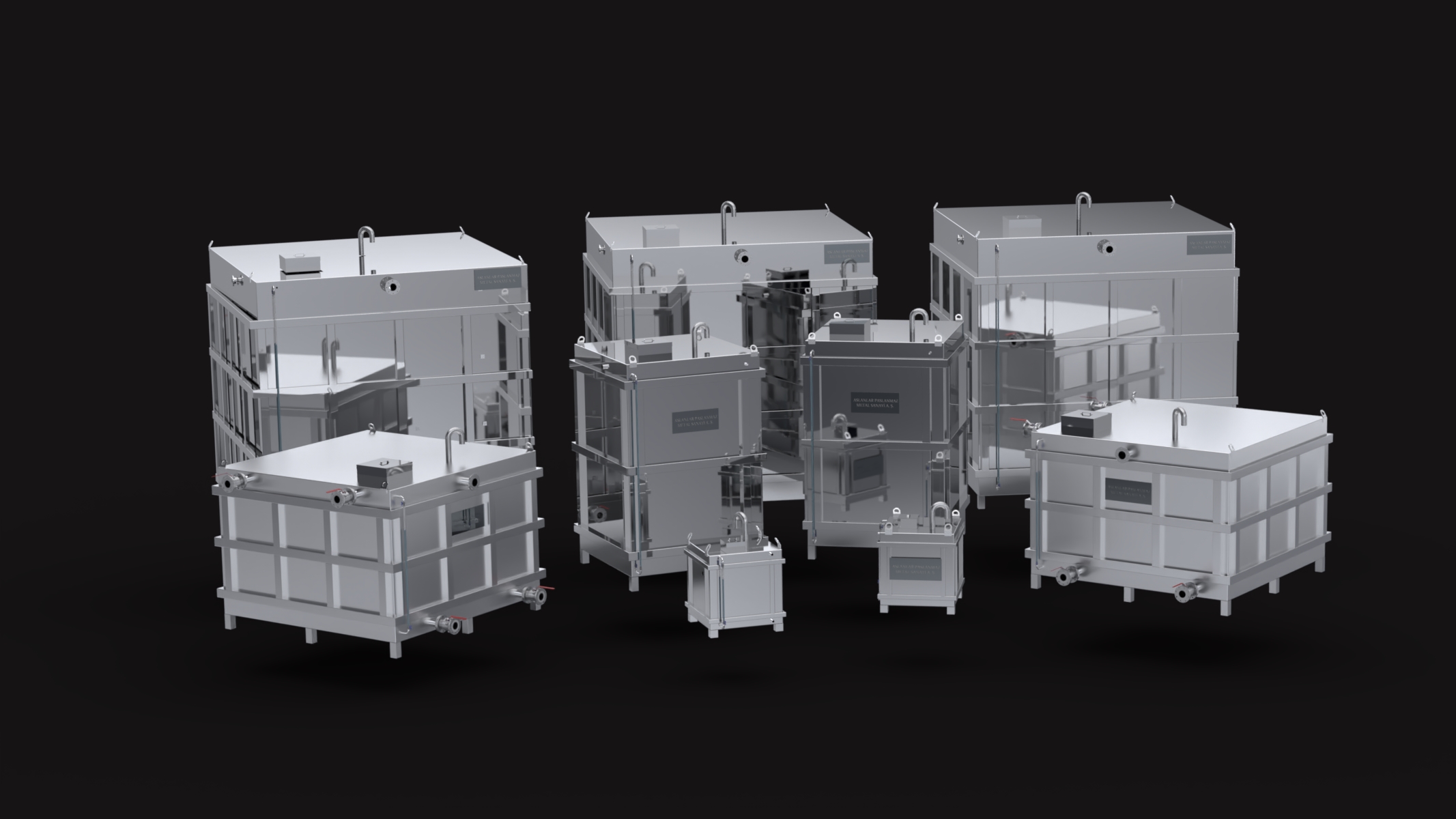

What is Prismatic Tank?

Prismatic stainless storage is a storage solution produced from stainless steel materials as a design and production process. Such warehouses are generally used in areas such as the food industry, chemical industry, agriculture and livestock. Since stainless steel is a preferred material due to its features such as high corrosion resistance and longevity, prismatic stainless tanks are also preferred due to these features. Such warehouses are also preferred because they are easy to clean, provide hygienic conditions and are a reliable storage solution.

What are the usage areas of prismatic square storage tanks?

Prismatic stainless tanks are generally used in areas such as food industry, chemical industry, agriculture and livestock. In these areas, it is used to protect the hygienic conditions of the materials during storage and to protect them from corrosion. For example, in the food industry, prismatic stainless warehouses where products are stored are designed and produced to prevent deterioration of products. Likewise, in the chemical industry, prismatic stainless tanks where various chemicals are stored are designed and produced so that the substances do not interact. In agriculture and livestock areas, prismatic stainless warehouses where products are stored are used to protect the hygienic conditions of the products. Such warehouses can also be used in various trade centers, warehouse and stock areas.

Prismatic stainless tanks can be preferred in areas where various food products are stored, as they provide hygienic conditions. For example:

Fruits and vegetables: Fruits and vegetables can stay fresh longer when they are stored in prismatic stainless tanks in a way that ensures hygienic conditions.

Food products: Food products can be used in prismatic stainless tanks, especially for products that are at risk of being affected by corrosion. Food products stored in such warehouses can stay fresh for a longer period of time due to hygienic conditions.

Beverages: When drinks are stored in prismatic stainless tanks in a hygienic manner, the risk of spoilage is reduced and they can stay fresh for longer.

Milk and dairy products: Milk and dairy products can stay fresh longer in prismatic stainless warehouses as they provide hygienic conditions. The risk of deterioration of milk and dairy products stored in such warehouses is reduced and hygienic conditions are provided.

These examples are just a few examples, and prismatic stainless warehouses can be preferred in areas where various other food products are stored. The important thing is that the stored materials are stored in warehouses made of stainless steel materials in order to ensure hygienic conditions and not be affected by corrosion.

Prizmatik kare depo tank özellikleri nelerdir?

Prismatic stainless tanks and stainless liquid tanks are generally produced from stainless steel materials. Stainless steel is used in storage operations and tanks where liquids are stored, due to its resistance to corrosion. Stainless steel materials can be processed and shaped by various methods and produced in desired shapes.

The production process of prismatic stainless tanks and stainless liquid tanks generally includes the following steps:

Material selection: First, the material to be used for production is selected. Stainless steel is a preferred material among materials used in the food industry, chemical industry, and agriculture and livestock.

Measurement and design: According to the desired dimensions, the design of the tank or tank is made. In this step, the shape, size and characteristics of the tank or tank must be determined.

Cutting: Stainless steel material is cut into desired shapes and made ready for processing.

Shaping: The cut material is shaped into desired shapes by shaping. In this step, various parts of the tank or tank are shaped according to presses and machines.

Joining: The shaped parts are combined to form the entire tank or tank. In this step, the parts need to be joined and glued correctly.

Test and quality control: The warehouse or tank produced is checked whether it has the desired properties by testing and quality control.

Export and distribution: The warehouse or tank produced is exported or put on the market directly from production.