Stainless tahini tanks play a critical role in the process from the production process of tahini to its delivery to the consumer. Since tahini is a food product with high fat content, it is very important to provide correct storage conditions. In this context, stainless steel tanks offer an indispensable solution in terms of hygiene, durability and food safety.

What is a Stainless Tahini Tank?

Stainless tahini tank is a type of container specially designed for the production and storage of tahini. These tanks are generally made of stainless steel and have features such as high durability, corrosion resistance, hygiene and easy cleanability. It is widely used in the food industry for storing sensitive products such as tahini.

Advantages of Stainless Steel Material

Stainless steel is the preferred material in the production of tahini tanks. The most important reason for this is that stainless steel has superior resistance to corrosion. Additionally, stainless steel tanks provide a hygienic environment and do not leak any harmful substances into the food. These tanks, which offer long-lasting use, are not only an economical choice for businesses, but also play a critical role in ensuring food safety.

The Importance of Storage in the Tahini Production Process

During the tahini production process, the quality of storage directly affects the quality of the final product. Improper storage conditions may cause tahini to deteriorate and lose flavor. Therefore, the quality of tahini tanks and their compliance with hygiene standards are of great importance. Stainless tahini tanks ensure that tahini remains fresh and delicious for a long time.

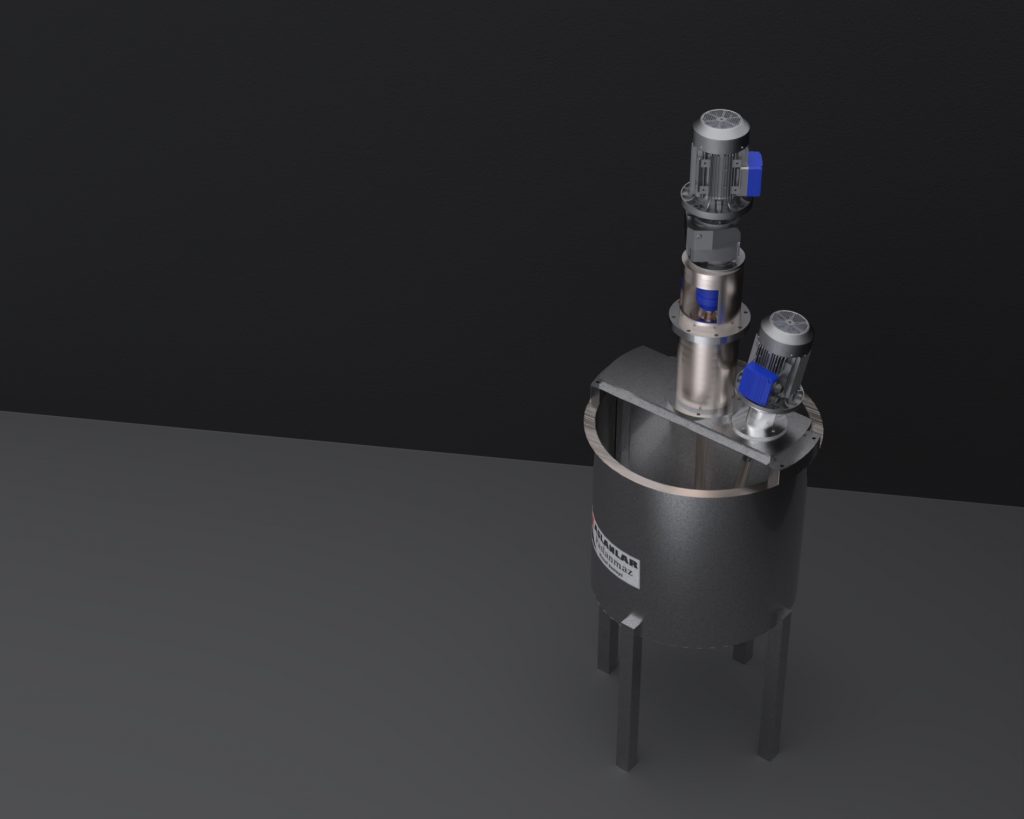

Different Capacities of Stainless Tahini Tanks

Stainless tahini tanks are produced in various capacities to suit different production scales. While smaller tanks are preferred for small-scale producers, large capacity tanks are required for businesses engaged in industrial production. This flexibility allows businesses to choose the tank that best suits their needs.

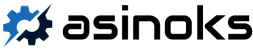

Tank Design and Customization Options

Since every business has different needs, stainless tahini tanks offer a variety of design and customization options. In addition to standard designs, tanks specially produced according to the customer’s needs are also available. In this way, tanks fit perfectly into production processes.

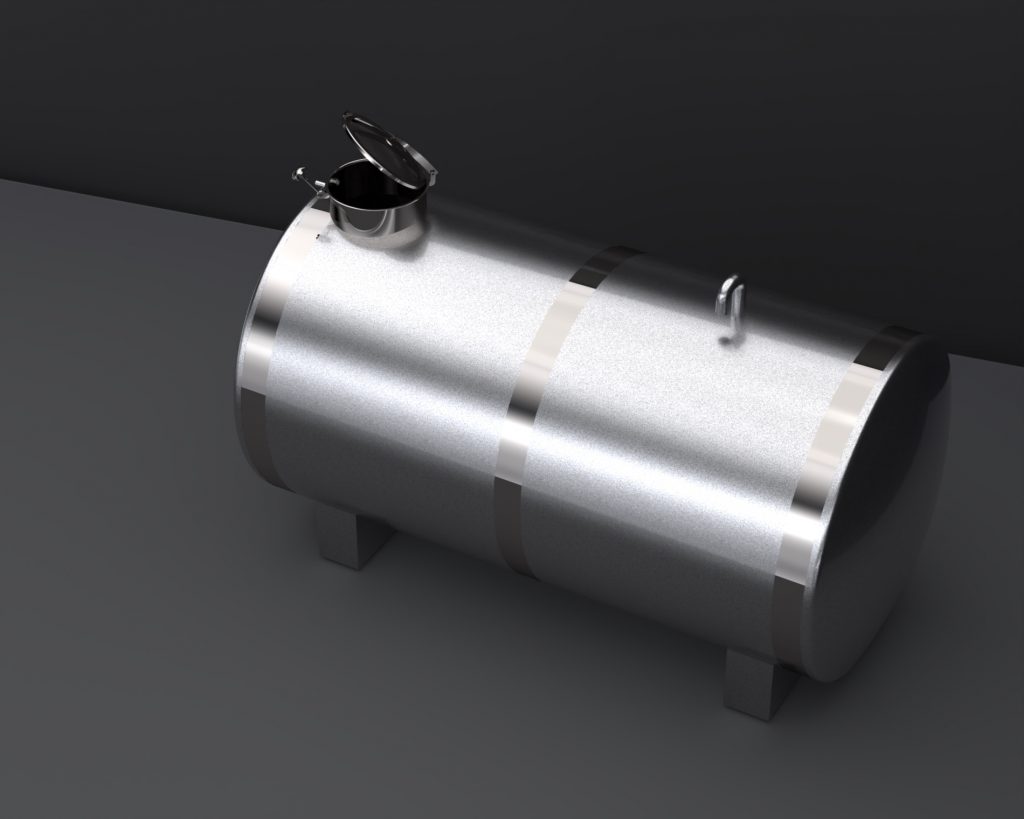

Hygiene and Ease of Cleaning

One of the biggest advantages of stainless tahini tanks is that they are easy to clean. The inner surface of the tanks is designed to prevent the accumulation of residues that could harm food. This feature ensures that tahini always remains fresh and hygienic and keeps food safety at the highest level.

Energy Efficiency and Thermal Insulation

The energy efficiency of tahini tanks provides long-term savings for businesses. Thanks to thermal insulation, tahini is stored at the ideal temperature. This both reduces energy costs and preserves the quality of tahini.

Economic Benefits of Stainless Tahini Tanks

Stainless tahini tanks provide significant economic benefits to businesses in the long term. Thanks to their durable construction, these tanks do not require frequent repairs and offer low maintenance costs. In addition, the stainless steel material ensures long-lasting use, which increases the return on investment of businesses.

Usage Areas of Tahini Tanks

Stainless tahini tanks are used not only in the food industry but also in various sectors. These tanks, which are widely preferred especially for the storage of liquid food products, also find a place in the cosmetics and chemical industries.

Things to Consider When Choosing a Stainless Steel Tahini Tank

When choosing a stainless tahini tank, compliance with quality standards is the most important factor. Additionally, the capacity and design of the tank must match the production needs of the enterprise. Purchasing from certified and reliable manufacturers ensures safe use in the long term.

Stainless Tahini Tank Manufacturers

Purchasing stainless tahini tanks from reliable manufacturers is critical for food safety and product quality. When choosing a manufacturer, the company’s experience in the sector and the guarantees it offers should be taken into consideration.

The Role of Stainless Tahini Tanks in the Future

Developments in food technologies have also caused the evolution of stainless tahini tanks. In the future, more efficient and environmentally friendly tanks will be produced in line with sustainability and environmentally friendly production approaches.

Stainless Tahini Tank Maintenance and Repair

Regular maintenance is essential to extend the life of stainless tahini tanks. Cleaning of tanks and timely repair of possible malfunctions are of great importance in maintaining product quality.

Stainless tahini tanks offer an indispensable solution in tahini production and storage. Providing durable, hygienic and economic advantages, these tanks stand out as a long-term and safe storage option in the food industry.

Stainless tahini tanks can be used for decades with proper maintenance.

Tanks should be cleaned regularly in accordance with food safety standards.

Prices vary depending on the tank capacity and customization options.

It is used in various sectors such as food, cosmetics and chemistry.

Quality certificates, manufacturer’s warranty and the tank’s capacity suitable for the business are important.