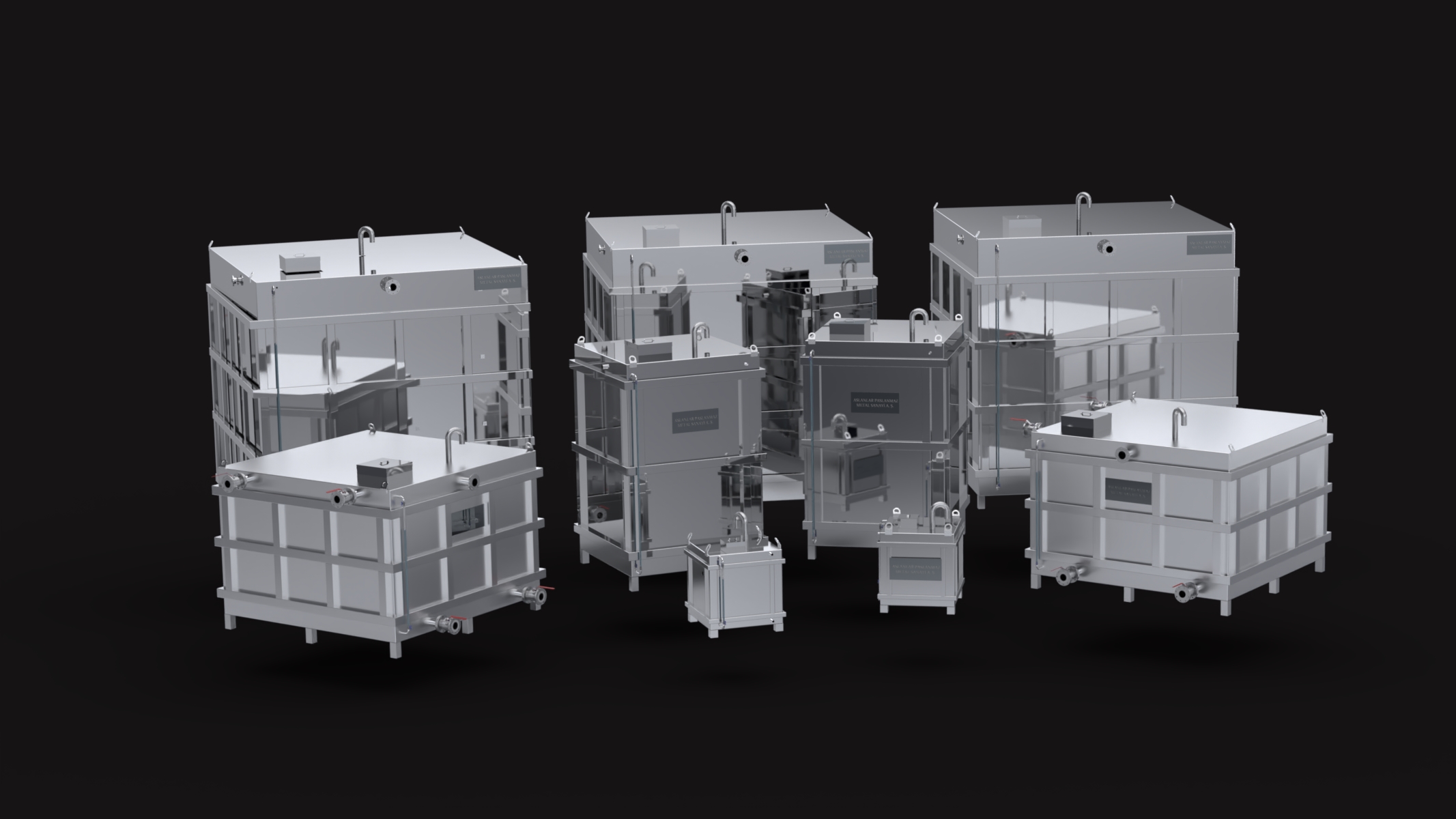

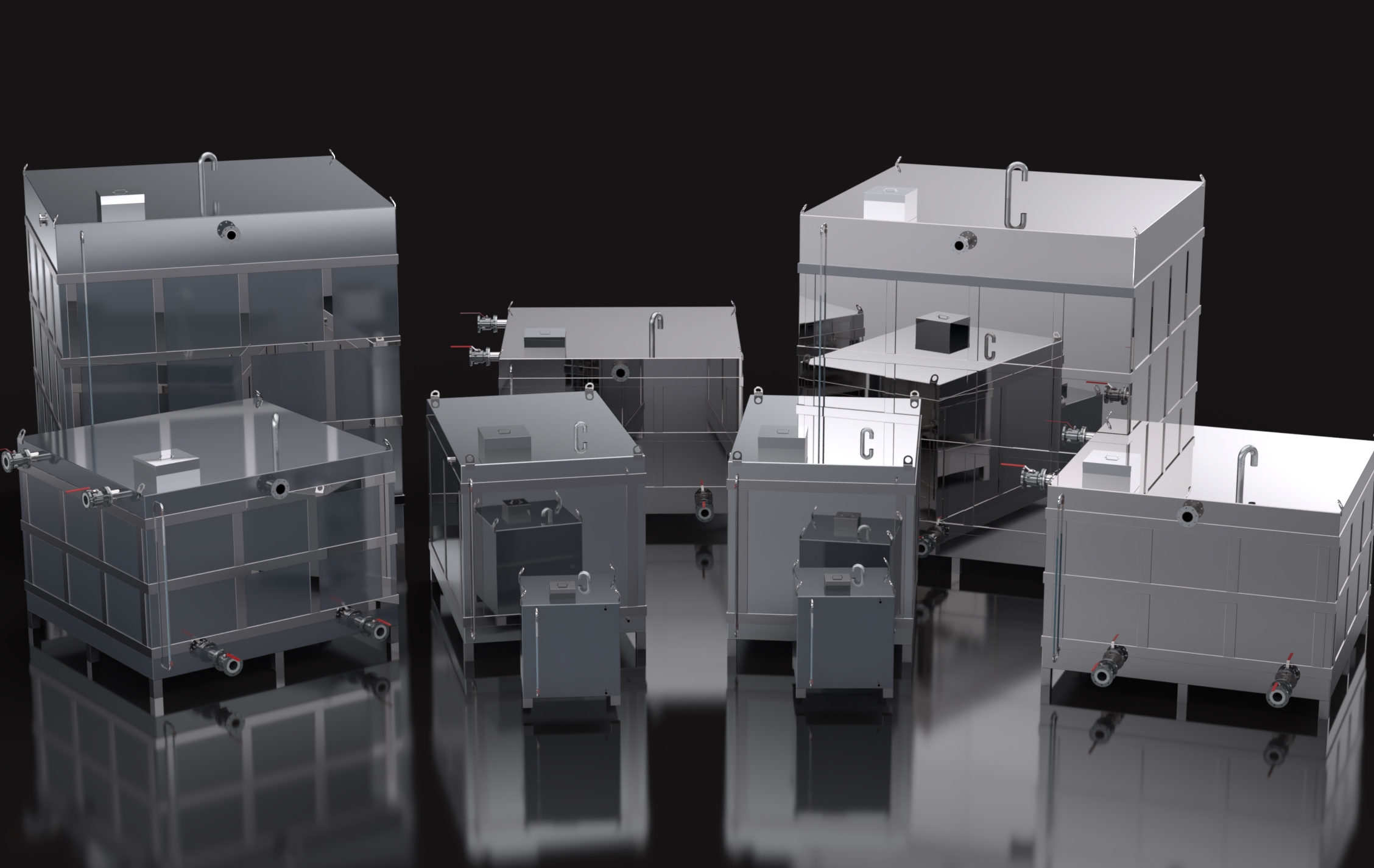

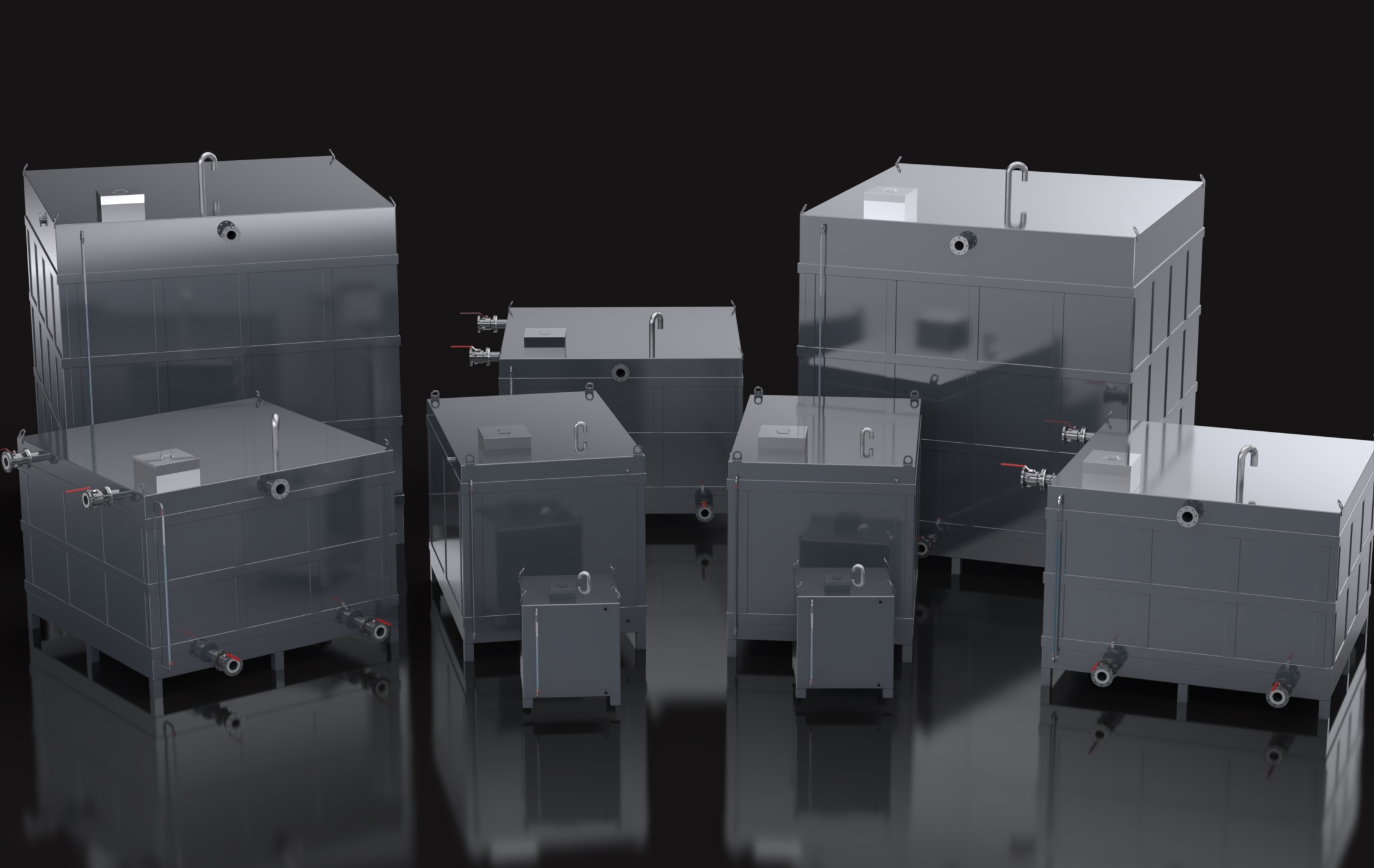

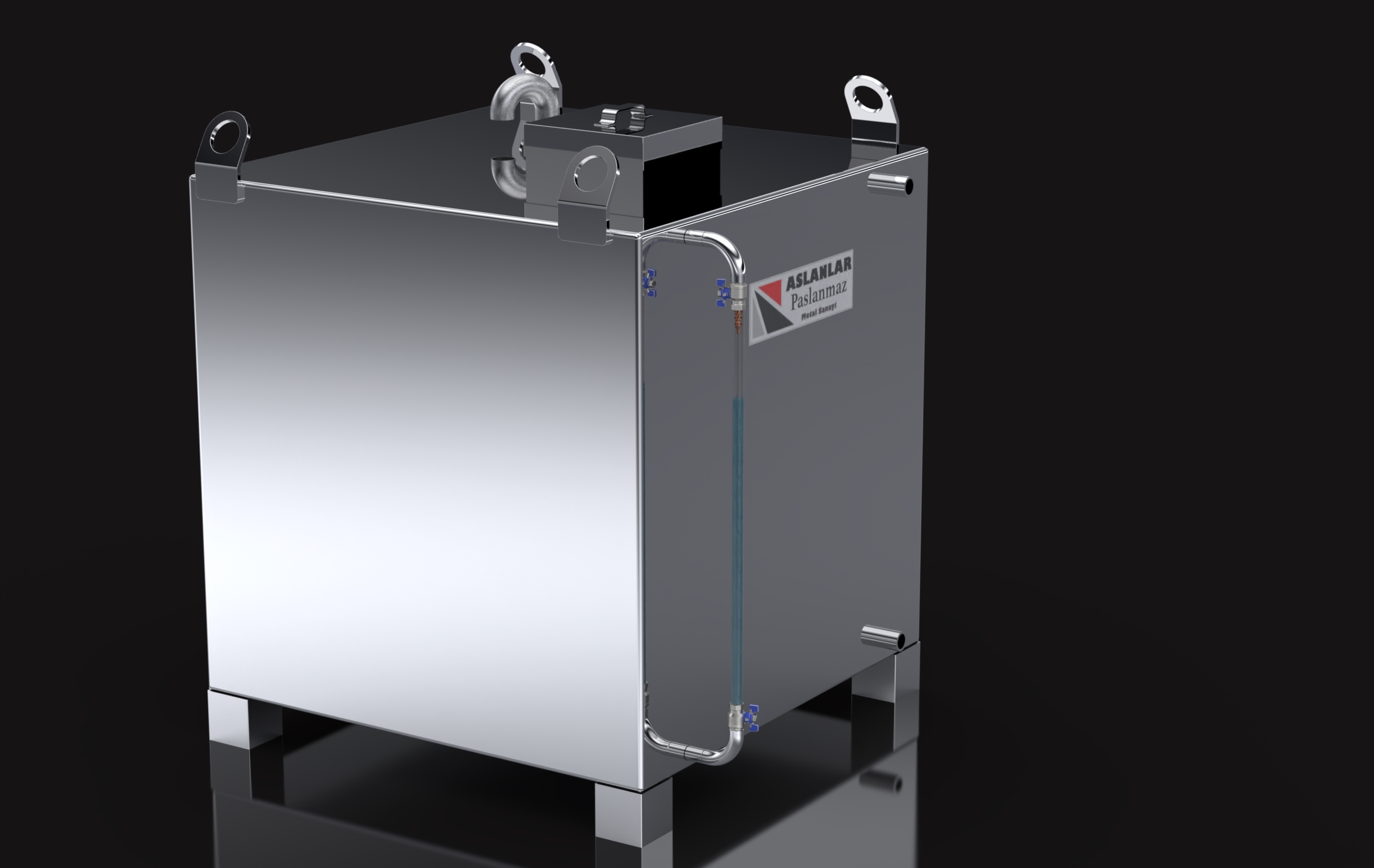

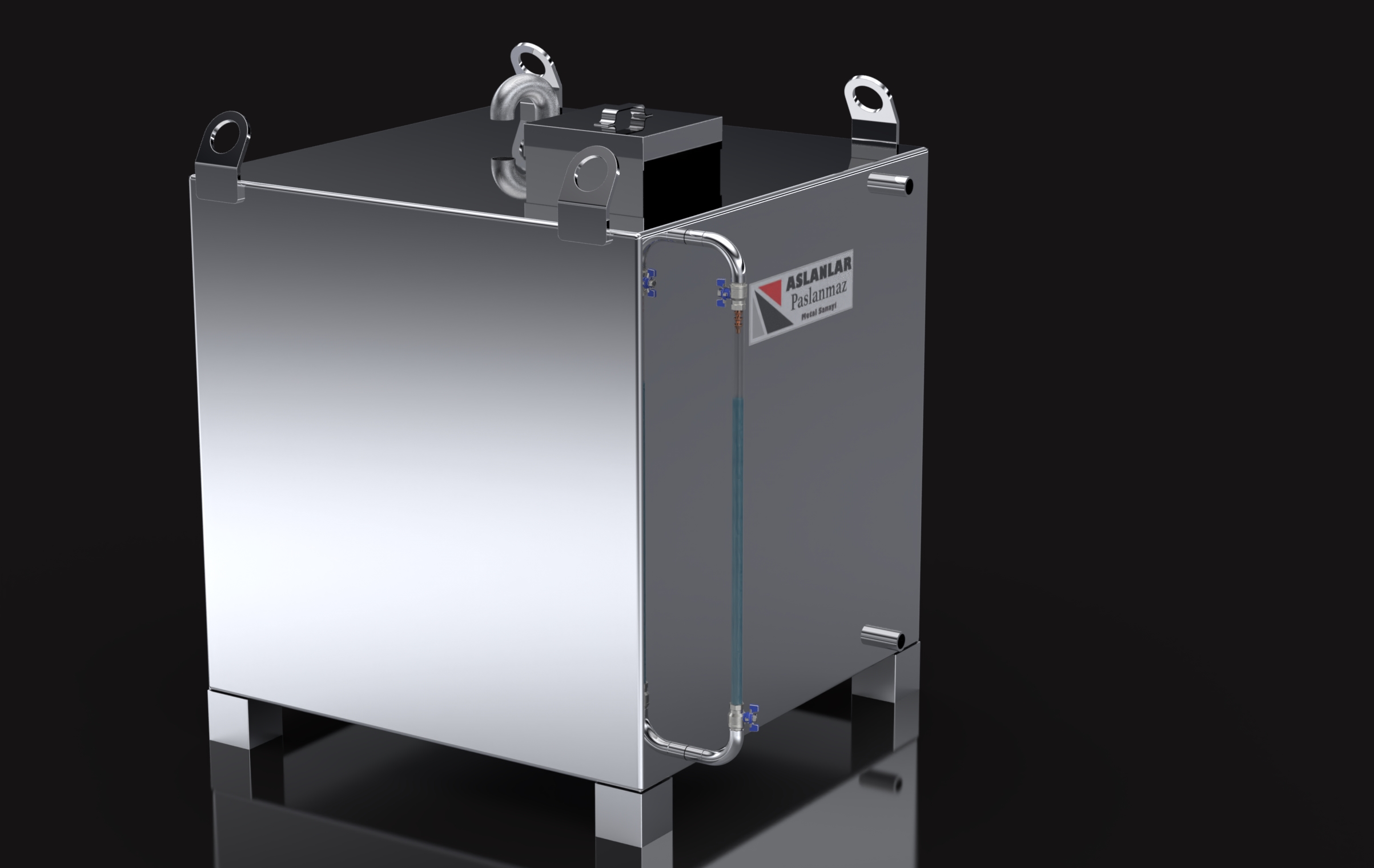

What are Prismatic Tanks?

Prismatic tanks are modern storage systems made of stainless steel, offering high hygiene, durability, and a long lifespan. Used safely in sectors such as food, chemistry, agriculture, and livestock, these tanks ensure that contents are protected from corrosion and stored in a healthy manner.

Stainless steel plays a significant role in making prismatic tanks stand out with its easy-to-clean surface and high corrosion resistance. These structures provide both product safety and a long-term investment advantage by reducing maintenance costs.

Prismatic tanks and reservoirs are produced in different sizes according to their tonnage and volume. Size and capacity options are available to suit specific needs.

10-Ton Prismatic Stainless Tank Dimensions

Width 2000 mm

Length 3000 mm

Height 1700mm

Sheet Thickness base 3mm

body 2mm

15-Ton Prismatic Stainless Tank Dimensions

Width 2500 mm

Length 3000 mm

Height 2000mm

Sheet Thickness 2mm

20-Ton Prismatic Stainless Tank Dimensions

Width 3000 mm

Length 3500 mm

Height 2000mm

Sheet Thickness 3mm

30-Ton Prismatic Stainless Tank Dimensions

Width 3000 mm

Length 4000 mm

Height 2500mm

Sheet Thickness 3mm

40-Ton Prismatic Stainless Tank Dimensions

Width 3250 mm

Length 5000 mm

Height 2500mm

Sheet Thickness 3mm

50-Ton Prismatic Stainless Tank Dimensions

Width 4500 mm

Length 5000 mm

Height 2500mm

Sheet Thickness 3mm

60-Ton Prismatic Stainless Tank Dimensions

Width 4000 mm

Length 6000 mm

Height 2500mm

Sheet Thickness 4mm

70-Ton Prismatic Stainless Tank Dimensions

Width 4000 mm

Length 7000 mm

Height 2500mm

Sheet Thickness 4mm

80-Ton Prismatic Stainless Tank Dimensions

Width 4000 mm

Length 7000 mm

Height 2750mm

Sheet Thickness 4mm

90-Ton Prismatic Stainless Tank Dimensions

Width 4000 mm

Length 7500 mm

Height 3000mm

Sheet Thickness 4mm

Where are Prismatic Tanks Used?

Prismatic stainless tanks are safely preferred in a wide variety of sectors:

Food Industry: Ensures that products like milk, fruit juice, liquid food, and additives are stored without spoilage and under hygienic conditions.

Chemical Industry: Allows for the safe storage of chemical substances without altering their structure.

Agriculture and Livestock: Contributes to the hygienic preservation of agricultural contents such as feed and liquid fertilizer.

Commercial Facilities and Production Areas: Widely used in storage, logistics, and transfer operations.

Prismatic tanks, which can be produced vertically or horizontally, both save space and can be manufactured in project-specific dimensions.

Use of Prismatic Tanks in the Food Sector

Prismatic stainless tanks are ideal, especially for storing food products freshly and safely:

Fruits and Vegetables: Preserves their freshness, prevents bacterial growth.

Beverages: Reduces the risk of spoilage, offers hygienic conditions.

Milk and Dairy Products: Provides storage compliant with hygiene standards.

Solid-Liquid Foods: The risk of corrosion is minimized, and product quality is preserved.

Thanks to their stainless surfaces that come into direct contact with the contents, these tanks offer both hygienic and healthy storage.

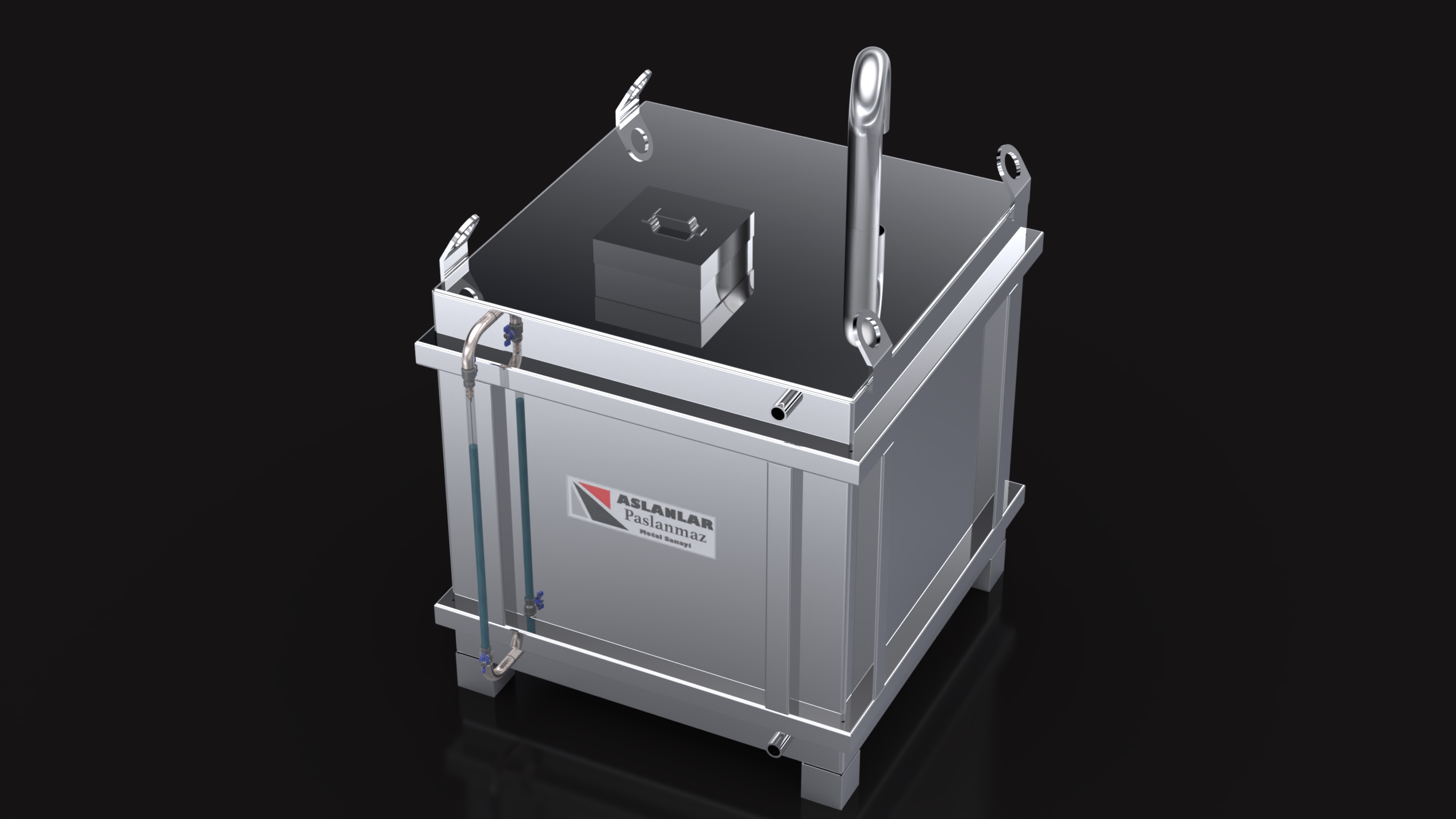

Features of Prismatic Tanks

Stainless Steel Body: It is resistant to corrosion and provides long-lasting use.

Hygienic Design: Suitable for food and chemicals, easy to clean.

Modular Production: Can be produced in different sizes and shapes.

Leak-Proof: Offers a fully sealed structure through high-quality welding and testing processes.

Aesthetic and Durable: Offers modern solutions in terms of both appearance and structural integrity.

Production Process of Prismatic Tanks

Material Selection: Stainless steel material is determined according to quality (304-316).

Design and Dimensioning: Detailed technical drawings are made specific to customer needs.

Cutting and Shaping: Precise cutting is performed with CNC laser, plasma, or water jet.

Welding and Assembly: The shaped parts are joined using leak-proof welding techniques.

Testing and Quality Control: Each tank is subjected to leak and strength tests.

Delivery and Installation: Shipments are made to domestic and international customers, and on-site installation is provided upon request.

Prismatic tanks are indispensable storage solutions for modern production, meeting industry standards for both hygiene and durability. With their long-lasting, aesthetic, and safe structures, they offer a sustainable investment for businesses.