Fittings Materials

- Home

- Fittings Materials

FITTINGS MATERIALS

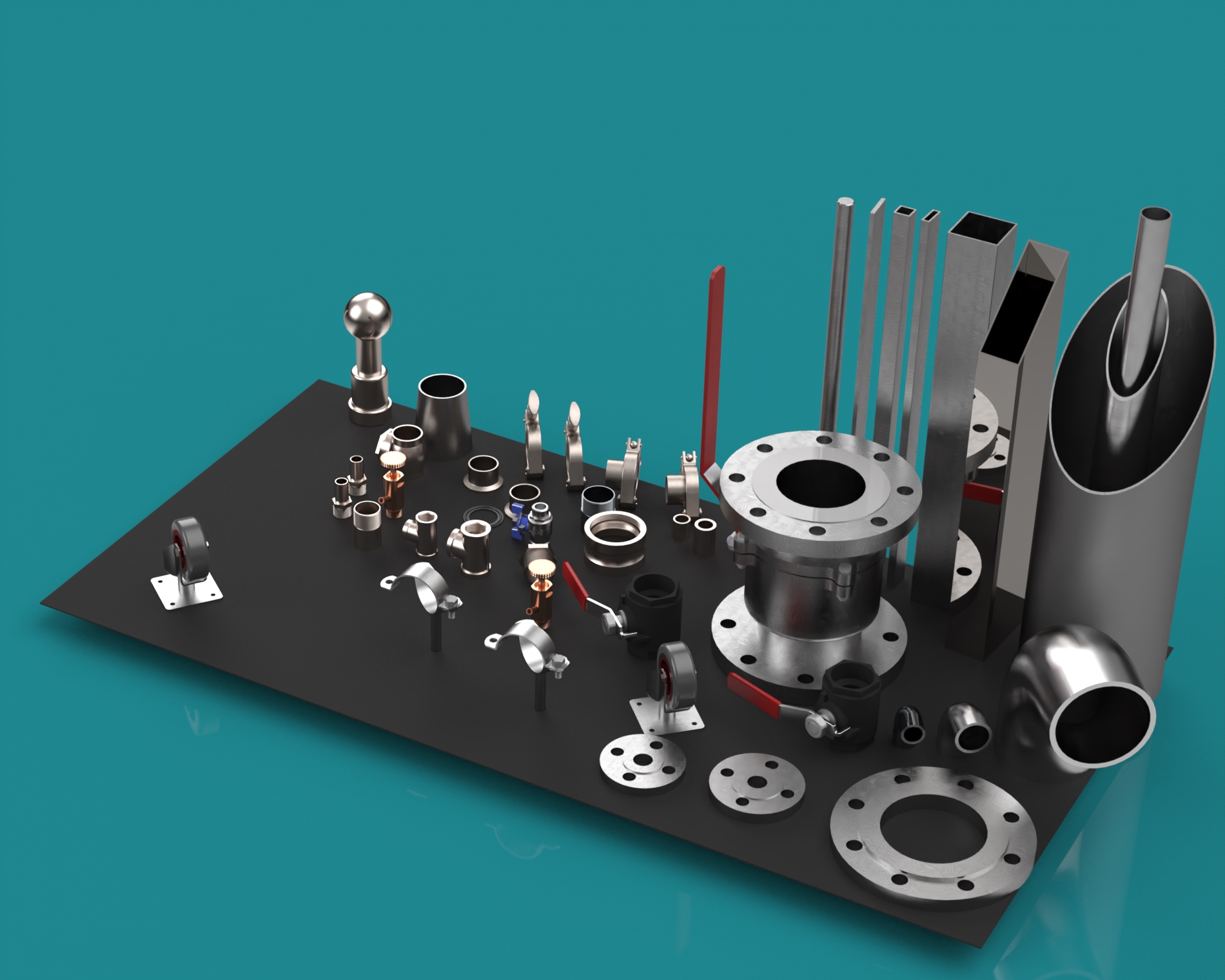

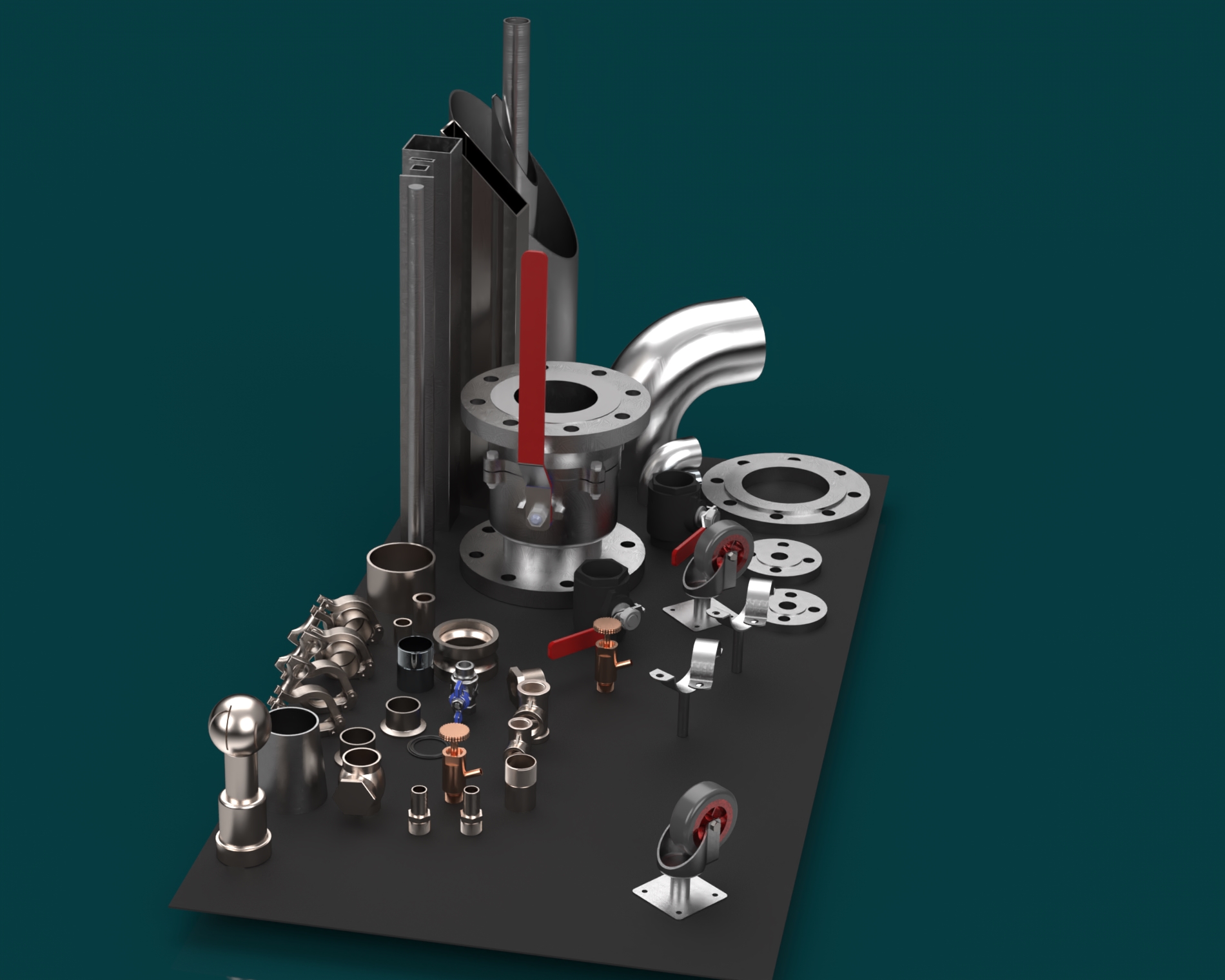

Stainless Steel Fittings and Installation Connection Elements

Stainless steel fittings and connection elements, which form the backbone of installation systems, ensure the safe transmission of water, gas, steam, and chemical fluids. The stainless steel valve, union, nipple, and elbow types we offer as Asinoks are manufactured from AISI 304/316 quality stainless steel, which is resistant to high pressure and corrosion.

Stainless Steel Fittings Types in Our Stocks

Our wide product range for your industrial and sanitary installation projects:

- Ball Valve: 2-Piece and 3-Piece options

- Unions: Female and Male Threaded Conical Union, Hose Union

- Nipples: Single-Sided, Proportional, and Full Nipple

- Elbows: 45° and 90° Stainless Steel Elbow, Tail Elbow

- Sleeve and Reduction: Stainless Steel Sleeve, Proportional Reduction

- T Connection: Equal T, Unequal T, and Hose T Connection

- Check Valve: Spring and Swing Stainless Steel Check Valve

- Other: Blind Plug, Crossover, and Special Connection Parts

Where are Fittings Materials Used?

Stainless steel connection elements play a critical role in all kinds of installation systems where hygiene and durability are essential:

- Water Installation: To prevent rusting and ensure sealing in drinking water lines.

- Food Industry: Bacteria-resistant stainless steel unions and valves are used in milk and beverage lines.

- Chemical and Industrial: AISI 316 quality fittings, which are resistant to corrosion, are preferred in the transfer of acidic liquids.

- Steam and Gas Lines: Steel connection parts resistant to high temperature and pressure are used.

The Hidden Heroes of the Installation: Valve, Nipple, and Sleeve

What is a Stainless Steel Valve?

It is the most important part that provides fluid control. The stainless steel ball valve fully opens or fully cuts off the flow thanks to the perforated sphere inside. It is long-lasting thanks to its sealing gaskets (Teflon).

What Do Nipple and Sleeve Do?

A nipple is a short pipe piece with threads on both ends, usually connecting two internally threaded parts (e.g., a valve and a filter). A sleeve, on the other hand, is an internally threaded connection element used to connect two externally threaded pipes to each other.

Why is a Stainless Steel Check Valve Important?

It is a safety valve that allows the liquid to flow in one direction and prevents it from returning. It especially prevents water from flowing back and damaging the pump in hydrophore and pump systems.

Frequently Asked Questions

What is the Difference Between 304 and 316 Quality Fittings?

AISI 304 quality is an economical and durable option for standard water and air installations. AISI 316 quality, on the other hand, is used in salt water, acid, and chemical lines with a high risk of corrosion thanks to the molybdenum it contains.

Which is Better, Threaded or Welded Connection?

Threaded fittings (screwed), which can be disassembled and reassembled, are preferred in places that require maintenance and part replacement. However, welded fittings are safer in fixed lines where high pressure and 100% sealing must be guaranteed.

Do Fittings Materials Rust?

A quality stainless steel fitting never rusts when used in the correct environment (e.g., 316 quality in an acid line). However, “galvanic corrosion” may occur when a stainless steel part is attached to an iron installation, so it is recommended that the entire line be stainless steel.