Choosing an industrial-grade stainless steel mixer is a decision that directly affects your business’s efficiency and product quality. An incorrect choice can lead to wasted time, increased energy consumption, and even product spoilage. So, what should you pay attention to when making this critical decision? We, Asinoks – Aslanlar Paslanmaz Metal Sanayi, are here to guide you through this process.

Clearly Define Your Needs

First and foremost, it is important to understand the purpose for which the mixer will be used. What types of materials will you be mixing? How long will the mixing process take? Does the mixing speed need to be adjustable? What is your production volume? The answers to these questions will help you determine the right type of mixer. For example, high-viscosity materials require a more powerful motor and specially designed mixing blades, while low-viscosity liquids may only require a simpler mixer.

Mixer Type Selection Criteria

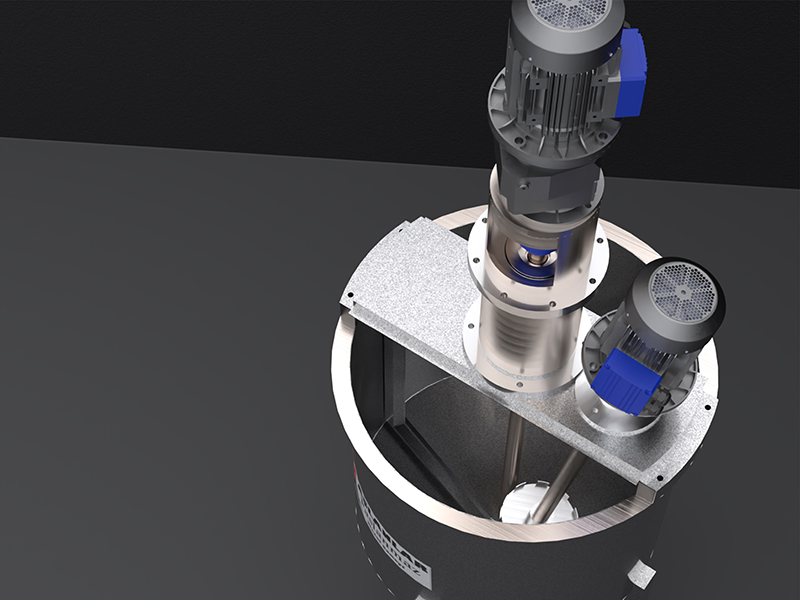

There are different types of industrial mixers on the market. These include propeller mixers, turbine mixers, anchor mixers, and helical mixers. Propeller mixers are generally suitable for low-viscosity liquids and are used to obtain a homogeneous mixture. Turbine mixers are a better option for higher viscosity liquids and provide more intense mixing. Anchor mixers are ideal for preventing buildup in areas close to the tank walls. Helical mixers are designed for very high viscosity materials and create a strong mixing effect. Choosing the right mixer type is critical for energy efficiency and mixing quality. Stainless Steel Mixers

Material Quality and Hygiene Standards

When choosing a stainless steel mixer, it is especially important to pay attention to the material quality. It is very important that the mixers used in the food, pharmaceutical and chemical industries are hygienic and easy to clean. Stainless steel is an ideal material for these industries due to its corrosion resistance, hygienic properties and long life. In addition, it must be ensured that all parts of the mixer comply with food safety standards. As Asinoks, we offer reliable and high-quality stainless mixer solutions to our customers by manufacturing in accordance with ISO 9001 Quality Management System and CE standards.

Energy Efficiency and Operating Costs

When choosing an industrial mixer, it is important to consider not only the initial cost but also the operating costs. An energy-efficient mixer can save a significant amount in the long run. Factors such as the mixer’s motor power, mixing speed and operating time affect energy consumption. In addition, regular maintenance and repair of the mixer also helps to reduce operating costs. As Asinoks, we help our customers reduce their operating costs by offering energy-efficient and long-lasting mixers.

The Role of Stainless Steel Mixers in Industrial Production

Choosing the right industrial type mixer is vital for the success of your business. By clearly defining your needs, paying attention to material quality and considering energy efficiency, you can choose the most suitable mixer. As Asinoks, we are happy to offer you customized solutions with our experienced engineering staff and state-of-the-art production line. Contact us for the most suitable stainless steel mixer solutions for your needs and increase the efficiency of your business.