Stainless Steel Profile | Durability and Applications

Stainless Steel Profile | Durability and Applications

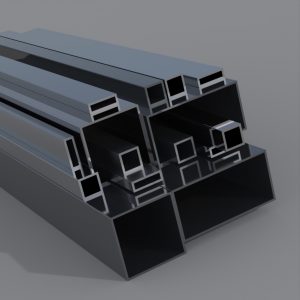

- What is a Stainless Steel Profile?

Stainless steel profile is a material made of stainless steel, usually found in square, rectangular, round, or specially sectioned forms, and stands out with its durability and aesthetic appearance. Thanks to its superior resistance to corrosion, it is used in many different sectors.

General Features of Stainless Steel Profile

- Corrosion Resistance: Resistant to factors such as water, moisture, and acid.

- Durability: High mechanical strength and heavy load carrying capacity.

- Aesthetic Appearance: Has a bright and modern surface.

- Easy Workability: Operations such as cutting, welding, and drilling can be easily applied.

- Hygienic and Recyclable: Especially preferred in the food and health sectors.

- Stainless Steel Profile Types

Stainless steel profiles are produced in various forms according to different usage areas and aesthetic needs.

Main Profile Types

- Square Stainless Steel Profile: Widely used in the construction sector with its symmetrical structure.

- Rectangular Stainless Steel Profile: Frequently preferred in the furniture, construction and decoration sectors.

- Round Stainless Steel Profile: Used in pipe systems, railings and medical devices.

- Special Sectioned Profiles: These are profiles produced in special shapes according to customer requests.

- Stainless Steel Profile Material Grades

Stainless steel profiles are divided into different quality classes according to the alloy ratios they contain.

| Quality Type | Properties | Usage Areas |

| 304 Quality | The most widely used quality, high corrosion resistance | Food, kitchen equipment, decoration |

| 316 Quality | Seawater and chemical resistant | Shipbuilding, chemical industry |

| 430 Quality | Magnetic, low corrosion resistance | Decorative and interior applications |

- Stainless Steel Profile Production Process

Stainless steel profiles are shaped by various processes starting from raw steel.

- Raw Material Preparation: Mixture of chromium, nickel and other alloys.

- Melting and Casting: Molten steel is cast.

- Shaping: Converted into profiles by hot or cold rolling.

- Surface Treatment: Processes such as polishing and brushing are applied.

- Quality Control and Packaging: The final product is tested and prepared for shipment.

- Advantages of Stainless Steel Profiles

Some important advantages provided by stainless steel profiles are:

- Long-lasting: Stainless steel maintains its durability for years.

- Requires Easy Maintenance: It is simple to clean and maintain.

- Offers Aesthetic Appearance: Preferred in modern architectural projects.

- Resistant to Chemicals: Resistant to factors such as acid, base and water.

- Stainless Steel Profile Usage Areas

Stainless steel profiles have a wide range of uses:

- Construction and Building Sector: Bridges, buildings, railings

- Furniture and Decoration: Tables, chairs, shelving systems

- Food and Health: Industrial kitchen, medical devices

- Automotive: Exhaust systems, chassis parts

- Maritime: Shipbuilding, pier and marina equipment

- Things to Consider When Choosing a Stainless Steel Profile

- Material Quality: The appropriate steel grade should be selected for the area of use.

- Surface Treatment: Glossy, matte or brushed surface options should be evaluated.

- Price-Performance Analysis: The best quality should be selected according to the appropriate budget.

Frequently Asked Questions (FAQ)

- What is the lifespan of a stainless steel profile?

It can last 50 years or more under proper maintenance and usage conditions.

- Can stainless steel profiles be welded?

Yes, it can be easily joined with TIG and MIG welding methods.

- Do stainless steel profiles rust?

It does not rust when the correct quality is selected and maintained.

- How do stainless steel profile prices vary?

Material quality, thickness and exchange rate are the determining factors of prices.

- Which is the most durable stainless steel profile?

316 quality stainless steel has the highest corrosion resistance.

For More Detailed Information Click Here.