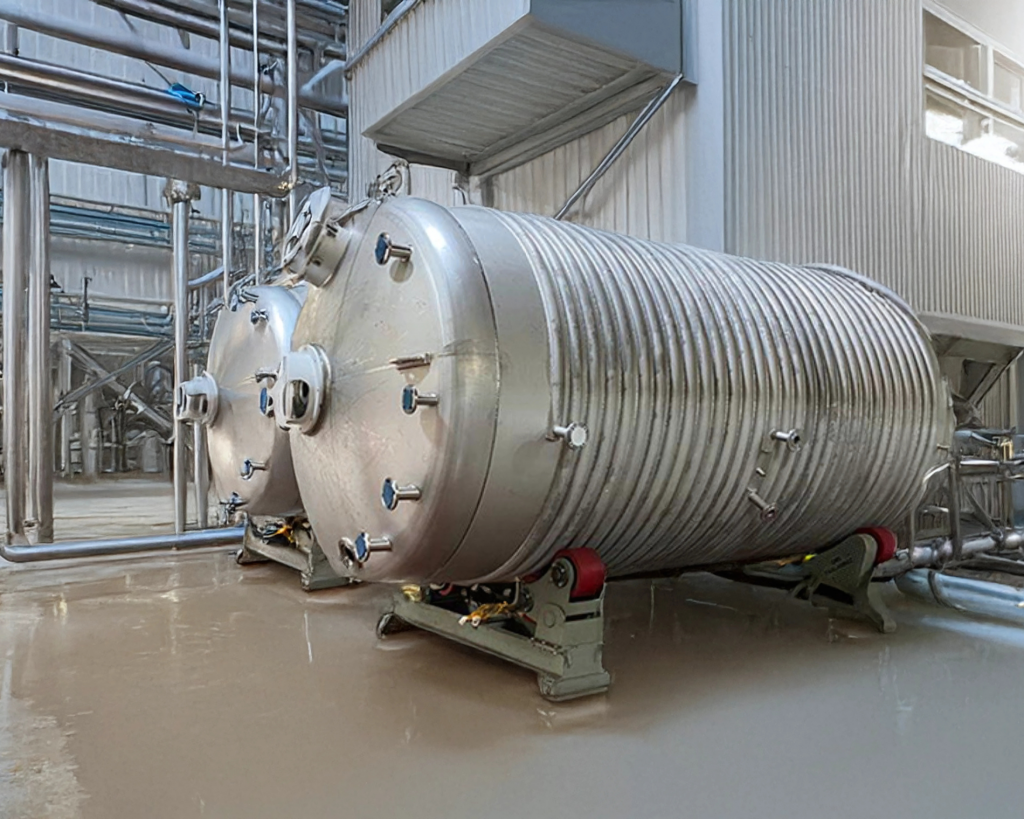

A serpentine reactor is a type of reactor that uses serpentine-shaped tubes to enhance heat transfer and ensure homogeneous mixing. These types of reactors are widely used in the chemical, food, pharmaceutical, and energy industries.

Structure and Working Principle of Serpentine Reactor

Serpentine reactors consist of a main body in which the reaction takes place and serpentine tubes located inside or outside this body. Serpentine tubes can be fed with a cooling or heating fluid to provide heat transfer during the reaction.

- Heat Transfer: Temperature control is important for the reaction to proceed efficiently. Serpentine coils draw or add heat via fluid circulating inside the reaction vessel.

- Mixing and Efficiency: Serpentine structures help distribute fluids homogeneously within the reactor, allowing the reaction to occur more stably.

- Energy Efficiency: Offers the possibility to operate at optimal temperature by consuming less energy.

Usage Areas of Serpentine Reactors

- Chemical Industry: Petrochemistry, polymer production, organic synthesis processes.

- Food Industry: Milk pasteurization, sugar production, beverage processing.

- Pharmaceutical Sector: Chemical syntheses, biotechnological productions.

- Energy Production: Processes such as biodiesel production, hydrogen production.

Advantages of Serpentine Reactors

- High Heat Transfer Capacity: Temperature control allows the reaction to proceed more stably.

- Homogeneous Mixture: Reduces side reactions by providing better mass transfer within the reactor.

- Modular Design: Can be adapted to different production capacities.

- Durability: Provides long-lasting use with corrosion-resistant materials.

Serpentine reactors offer highly effective solutions, especially in chemical processes that require heat control. Different materials and designs can be preferred according to the area of use and the type of reaction.

For More Detailed Information Click Here.