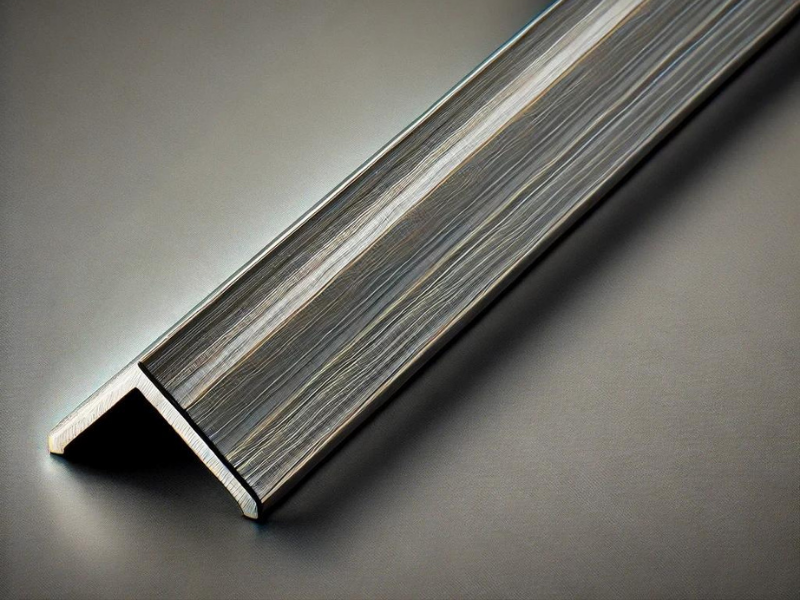

Stainless steel angle is a type of rust-resistant steel profile commonly used in the construction and industrial sectors. Angles have 90-degree angles and are typically manufactured in an “L” shape, used to support structural elements. The biggest advantage of stainless steel angles is their resistance to external factors and their long-lasting use.

Stainless Steel Angle Types

Stainless steel angles vary according to different needs and usage areas. The most commonly used stainless steel angle types are 304, 316, and 430 grades.

304 Stainless Steel Angle

304 grade stainless steel is one of the most widely used stainless steel types. It is a material with high corrosion resistance, reasonable cost, and preferred in most construction projects.

316 Stainless Steel Angle

316 grade stainless steel is widely used in the maritime and chemical industries. This material is resistant to high temperatures and more aggressive environmental conditions.

430 Stainless Steel Angle

430 grade is a more cost-effective option and is generally used indoors. It is preferred in projects where aesthetic requirements are at the forefront.

Features of Stainless Steel Angles

Stainless steel angles are known for their high corrosion resistance, strength, and long-lasting properties. They are also resistant to temperature and require low maintenance. These features make it an ideal material for both industrial and commercial projects.

Stainless Steel Angle Manufacturing Process

The production of stainless steel angles begins with melting and shaping raw materials at high temperatures. In this process, materials are combined with various alloys to increase their durability. Then, the angles are cut to the desired dimensions, and finally, their surfaces are smoothed.

Advantages of Stainless Steel Angles

The main advantages of stainless steel angles are:

Corrosion Resistance

Stainless steel material exhibits high resistance to moisture and chemicals. This feature allows it to be used outdoors or in aggressive environments.

High Strength

High strength allows stainless steel angles to be used in heavy load-bearing structures. It provides reliable support in construction and engineering projects.

Aesthetic Appearance

Stainless steel angles offer a modern and aesthetic appearance with their bright and clean surfaces. Therefore, they are also preferred in interior and decorative applications.

Usage Areas of Stainless Steel Angles

Stainless steel angles are used in many different sectors. Here are the main usage areas:

Construction Sector

In construction projects, stainless steel angles are used to support structures and provide stability. It is indispensable, especially in steel construction structures.

Machine Manufacturing

In machine and equipment manufacturing, stainless steel angles offer durable and long-lasting solutions. These products are frequently used in the fixing and assembly of machines.

Automotive Industry

Stainless steel angles are used in vehicle chassis and other critical parts in the automotive industry. It plays an important role in terms of durability and safety.

Food Industry

Hygienic and corrosion-resistant materials are needed in food processing plants. Stainless steel angles are an ideal solution for these environments.

Stainless Steel Angle Installation and Application

The installation of stainless steel angles is quite easy. It is mostly fixed with screws, rivets, or welding methods. Making correct measurements and placing the material properly during installation will increase the durability of the project.

What Should Be Considered When Purchasing Stainless Steel Angles?

There are a few important factors to consider when purchasing stainless steel angles. First of all, you should choose the stainless steel grade suitable for your project’s needs. Also, the dimensions and strength of the angle should be suitable for your usage area.

Differences Between Stainless Steel Angle and Carbon Steel Angle

There are some fundamental differences between stainless steel angle and carbon steel angle. Stainless steel is more resistant to corrosion, but carbon steel is more cost-effective. You can choose between these two materials according to the requirements of your project.

How Are Stainless Steel Angle Prices Determined?

The prices of stainless steel angles vary depending on the steel grade used, material quality, dimensions, and production method. Different dimensions and special production requests for special projects may affect the price.

Quality Control in Stainless Steel Angles

The quality control process is a critical step to ensure the durability and longevity of stainless steel angles. After production, the materials are subjected to various tests and their compliance with international standards is checked.

Recycling of Stainless Steel Angles

Stainless steel materials are recyclable. Stainless steel angles that have reached the end of their service life can be recycled and reused in the production of new products. This makes it an environmentally friendly option.