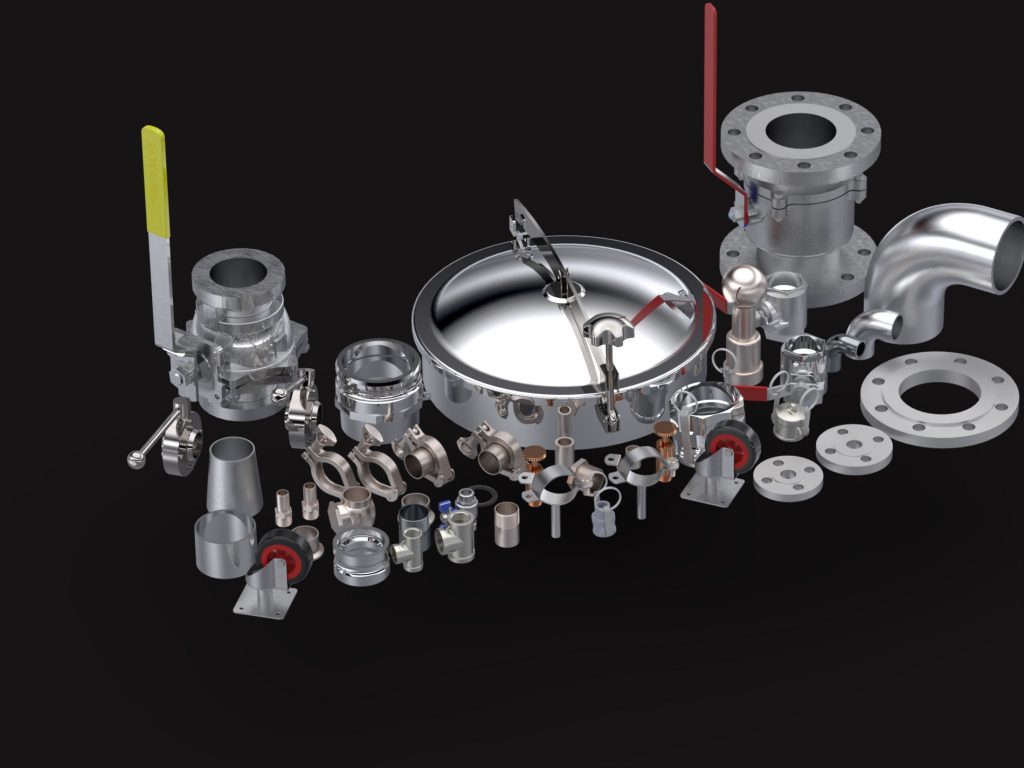

What are Stainless Steel Fittings?

Stainless steel fittings are parts made of stainless steel and used to provide connection in piping systems. They are frequently preferred in sectors such as chemical, food, pharmaceutical, and petroleum.

Thanks to their high corrosion resistance and long-lasting structure, stainless steel fittings are an ideal solution for water, gas, and liquid transportation.

Types of Stainless Steel Fittings

Stainless steel fittings are classified according to different connection methods and usage purposes. Here are the most common types of stainless steel fittings:

1. Welded Stainless Steel Fittings

- Allows stainless steel pipes to be connected to each other by welding.

- Offers a more robust and leak-proof connection.

- Used in transitions between diameters.

2️.Threaded Stainless Steel Fittings

- Has a screw connection system.

- Easy to assemble and disassemble.

- Widely used in small diameter pipe systems.

3️.Flanged Stainless Steel Fittings

- Used in large diameter pipe systems.

- Assembled with bolted connection method.

4️.Clamped Stainless Steel Fittings

- Used in hygienic installation systems.

- Easy to disassemble and install.

5️.Elbow and Tee Elbow Stainless Steel Fittings

- Used to change pipe orientations.

- Available in 45° and 90° angles.

Stainless Steel Fittings Production Process

Stainless steel fittings production consists of several carefully performed steps:

1️.Raw Material Selection: Stainless steel (304, 316, etc.) is determined.

2️.Cutting: Ensuring the steel is cut in appropriate sizes.

3️.Shaping: Shaped by pressing or forging.

4️.Heat Treatment: Material is hardened and durability is increased.

5️.Surface Treatment: Bright or matte surface coatings are applied.

6️.Testing and Certification: Passes quality control tests.

Stainless Steel Fittings Usage Areas

The sectors where stainless steel fittings are commonly used are:

- Food Industry: Preferred because of its hygienic and durable nature.

- Chemical and Petrochemical: Resistant to acids and chemicals.

- Maritime: Offers high corrosion resistance against salt water.

- Aviation and Defense: Resistant to high pressure and temperature.

- Water Treatment: Safely used thanks to the hygienic structure of stainless steel.

Stainless Steel Material Classes

The most common material classes from which stainless steel fittings are produced:

|

Material Type |

Properties |

|

304 Stainless Steel |

Suitable for general use, has moderate corrosion resistance. |

|

316 Stainless Steel |

Highly resistant to seawater and chemicals. |

|

321 Stainless Steel |

Used for high temperature applications. |

|

904L Stainless Steel |

Preferred in applications requiring extreme corrosion resistance. |

Things to Consider When Choosing Stainless Steel Fittings

- Usage Purpose: Material and type suitable for the sector should be selected.

- Pressure and Temperature Resistance: Must comply with operating conditions.

- Connection Type: Welded, threaded, or flanged type should be determined according to the need.

- Quality Certificates: Compliance with standards such as ISO, ASTM should be checked.

Frequently Asked Questions (FAQs) About Stainless Steel Fittings

1️.Do stainless steel fittings rust?

No, high-quality stainless steel fittings are resistant to corrosion. However, improper maintenance or the use of low-quality materials can lead to rusting.

2️.How are stainless steel fittings prices determined?

Prices vary depending on the steel grade, diameter, production method, and market conditions.

3️.What temperatures are stainless steel fittings resistant to?

304 stainless steel is resistant up to 870°C, while 316 stainless steel is resistant up to 925°C.

4️.Where to buy stainless steel fittings?

Should be purchased from reliable industrial suppliers and manufacturers. Certified products should be preferred.

5️.Should threaded or welded fittings be preferred?

Threaded fittings should be preferred in low-pressure systems, and welded fittings should be preferred in high-pressure and leak-proof systems.

6️.How to maintain stainless steel fittings?

Long-lasting use can be achieved with regular cleaning and chemical resistance tests.

Stainless steel fittings offer a reliable solution in industrial and domestic uses with their durability and long-lasting structure. When used with quality material selection and the correct connection method, they exhibit excellent performance in installation systems.