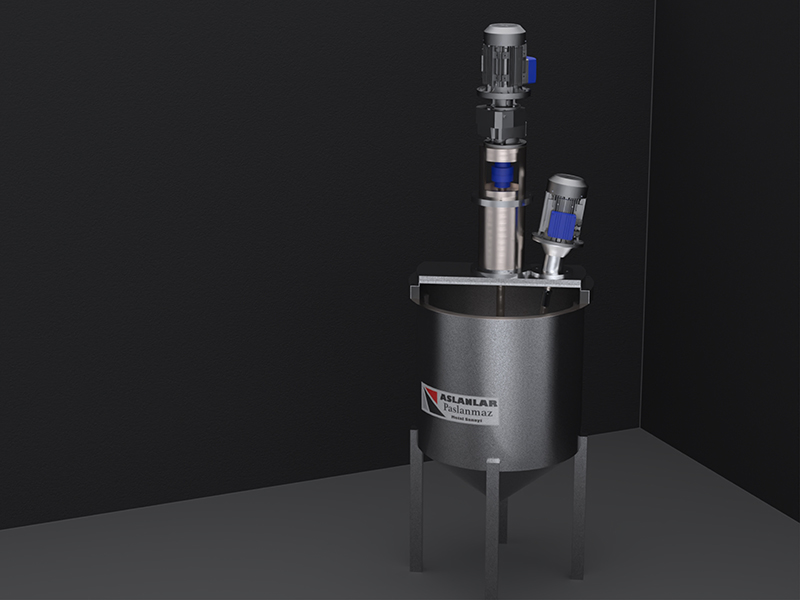

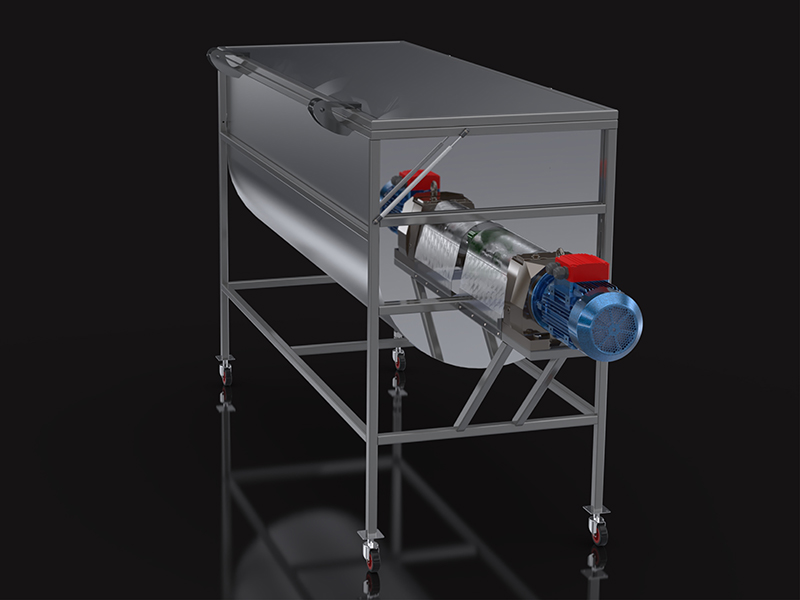

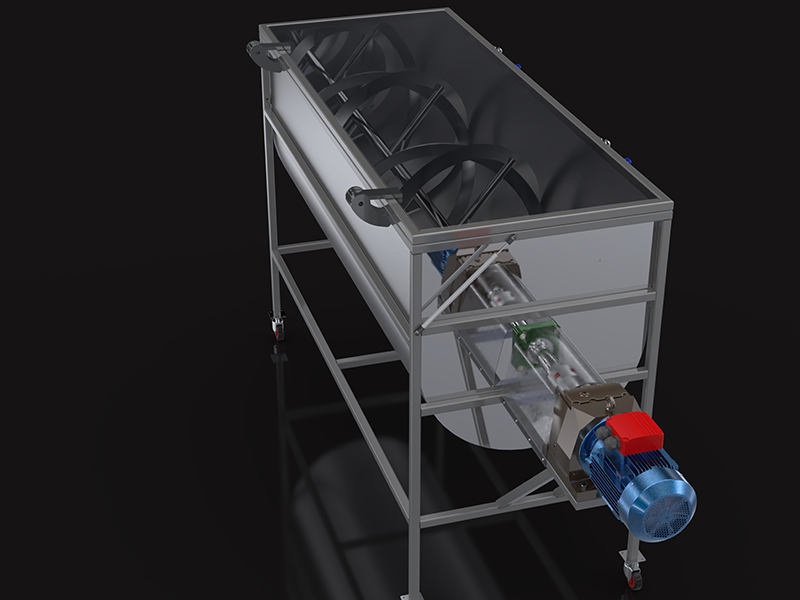

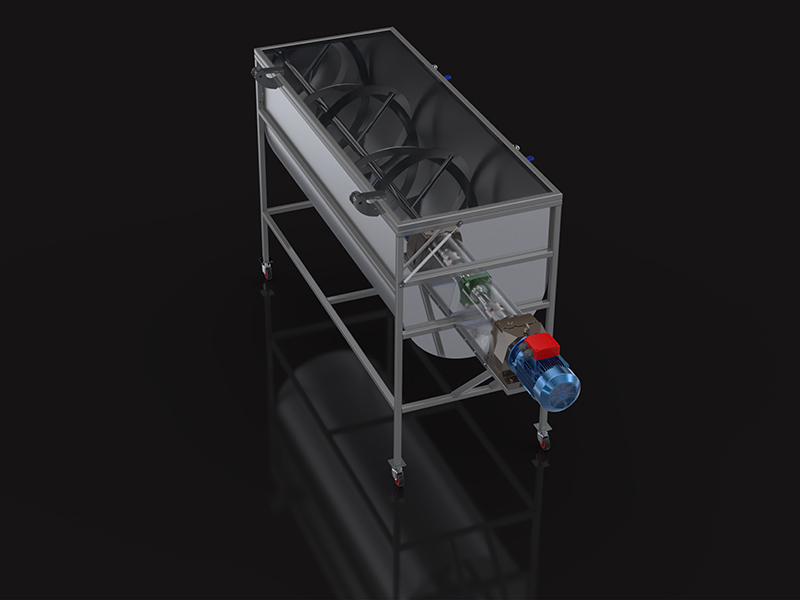

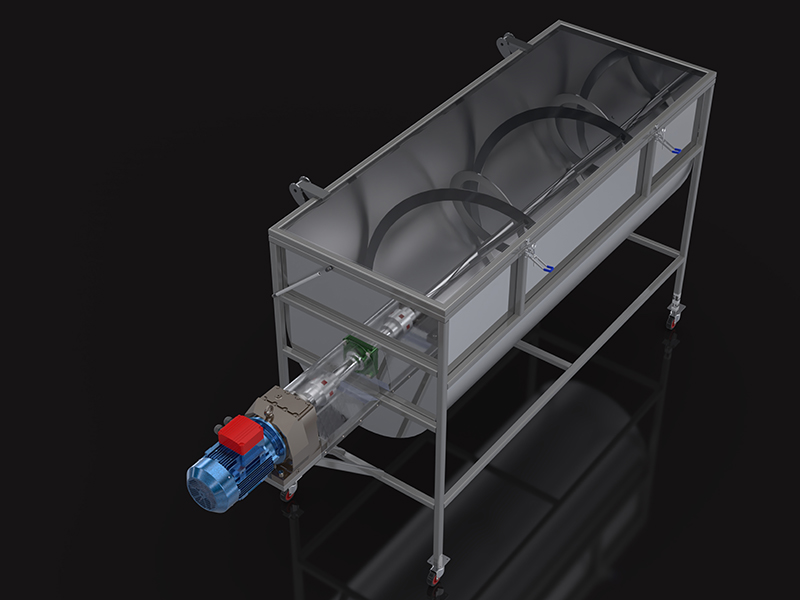

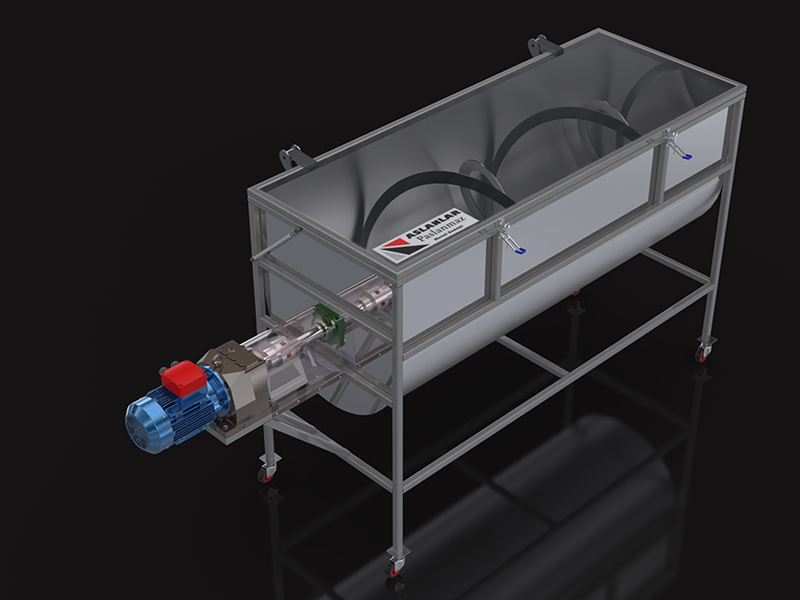

What is a Stainless Steel Mixer?

Stainless steel mixers are industrial equipment used to homogeneously mix various liquid and solid materials. These mixers, made of stainless steel, offer superior durability and hygiene.

Importance of Stainless Steel Mixers

Stainless steel mixers play an important role in the food, chemical, pharmaceutical, and many industrial sectors. They are used to improve product quality and production efficiency. In addition, being made of stainless steel ensures they are long-lasting and hygienic.

ASLANLAR Stainless Steel Metal Industry

General Information About the Company

ASLANLAR Stainless Steel Metal Industry is a leading company in the production of stainless steel products with over 30 years of experience. It holds a pioneering position in the sector with its high-quality standards and customer-oriented service approach.

Mission and Vision

ASLANLAR’s mission is to provide its customers with the highest quality products and to maintain its leading position in the sector. Its vision is to become a recognized brand in the global market with innovative solutions and advanced technologies.

Service Areas

In addition to manufacturing stainless steel mixers, water tanks and other stainless steel products, our company also sells stainless steel sheets, profiles, pipes, bar shafts and flanges.

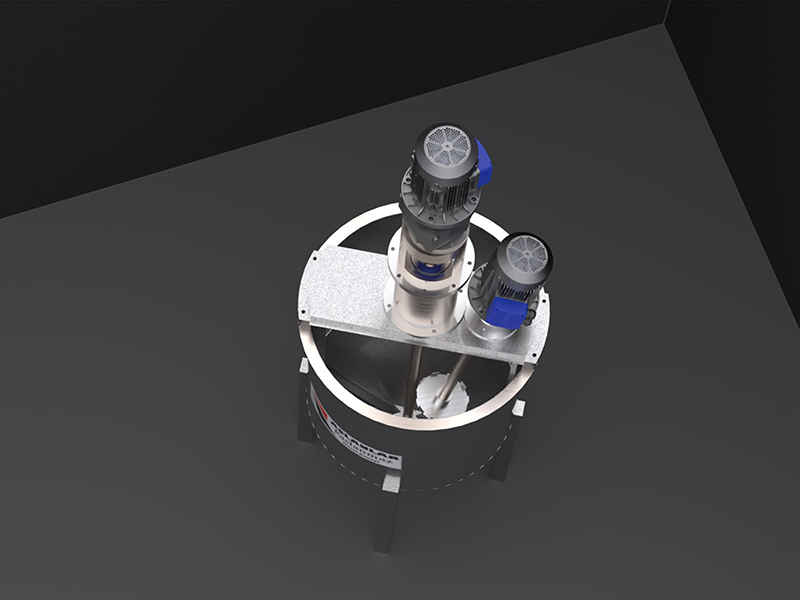

Types of Stainless Steel Mixers

Industrial Mixers

Industrial mixers are powerful and durable equipment designed for use in large-scale production facilities. They are ideal for high-volume mixing operations.

Laboratory Mixers

Laboratory mixers are used for small-scale and sensitive mixing operations. They are widely preferred in chemistry and biology laboratories.

Food Mixers

Food mixers are used in food production facilities for mixing products such as dough, sauces, and creams. They ensure food safety with their hygienic and stainless steel structure.

Chemical Mixers

Chemical mixers are used in the chemical industry for the homogeneous mixing of various chemicals. They are made of stainless steel material that is highly resistant to chemicals.

Advantages of Stainless Steel Mixers

Durability

Stainless steel mixers are long-lasting and durable as they are made of high-quality stainless steel material. They are resistant to harsh working conditions.

Hygiene and Health

Stainless steel surfaces do not allow the growth of bacteria and microorganisms, which provides a hygienic working environment. This feature is vital in the food and pharmaceutical industries.

Efficiency

Stainless steel mixers offer high efficiency for obtaining homogeneous mixtures. They provide time and cost savings in production processes.

Environmentally Friendly

Stainless steel is a recyclable material and does not harm the environment. It is an ideal option for sustainable production.

Stainless Steel Products and Other Services

Stainless Steel Products

ASLANLAR offers a wide range of products such as stainless steel sheets, profiles, pipes, bar shafts and flanges. These products, manufactured in accordance with high quality standards, can be used in various industrial applications.

Custom Manufacturing Services

ASLANLAR offers flexible and innovative solutions, manufacturing stainless steel products according to the special needs of its customers.

Stainless Steel Sheet and Profile Sales

Product Types

Our products such as stainless steel sheets, profiles, pipes and bar shafts meet different industrial needs. It offers a wide range of options to customers with its wide product range.

Quality Standards

ASLANLAR aims to ensure customer satisfaction by maintaining high quality standards in all its products. Our products have international quality certificates.

ASLANLAR’s Technical Infrastructure and Experience

Technological Investments

Our company constantly renews and improves its production processes with technological investments. It manufactures with modern production techniques and equipment in high quality standards.

Experienced Staff

Our expert staff provides quality service with years of experience and knowledge. It produces fast and effective solutions to customer needs.

Customer Satisfaction and Feedback

Customer Reviews

The positive feedback we receive from our customers proves our quality and reliability. Customer satisfaction is the most important priority for our company.

Usage Areas of Stainless Mixers

Industry and Industrial Use

Stainless steel mixers play a critical role in large-scale industrial and industrial production facilities. These mixers, used in the chemical, pharmaceutical and food industries, can withstand heavy working conditions thanks to their high capacity and durability. It is ideal for processes where large amounts of material need to be mixed homogeneously.

Food and Beverage Industry

In food production facilities, stainless steel mixers are widely used in mixing products such as dough, sauce, cream. Stainless steel materials are preferred in terms of food safety and hygiene because these materials are resistant to bacteria and contamination. It also ensures an even distribution during the mixing process of the products.

Chemical and Pharmaceutical Industry

In the chemical and pharmaceutical industries, stainless steel mixers are of critical importance in mixing various chemicals and drugs. These mixers offer high resistance and reliability to chemicals, thus ensuring high quality and safety in the production process.

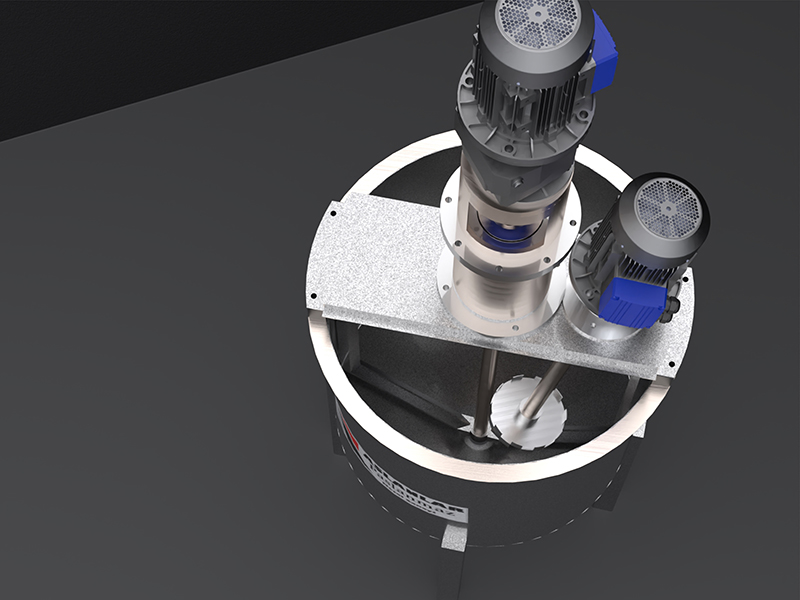

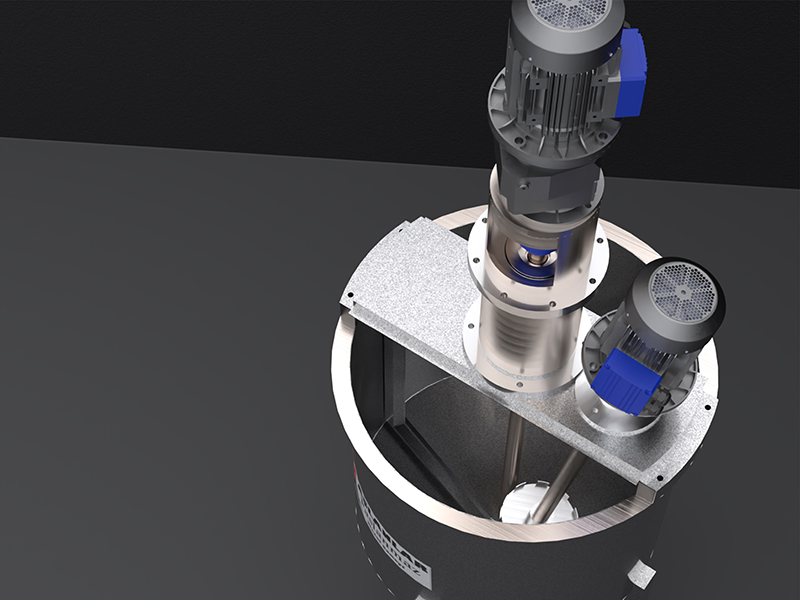

Stainless Steel Mixer Manufacturing Process

Design and Planning

The manufacturing process of stainless steel mixers begins with custom designs and planning according to customer needs. Engineering calculations and designs are made in line with the customer’s area of use and technical requirements. At this stage, the size, capacity, and other technical features of the mixer are determined.

Production Stages

In the production stage, high-quality stainless steel materials are used and processed with modern production techniques. Processes such as cutting, welding, assembly, and surface treatment are carried out meticulously. Quality control is ensured at every stage to guarantee the product’s durability and performance.

Quality Control

At the end of the manufacturing process, stainless steel mixers undergo detailed quality control processes. Criteria such as the product’s leak-proofness, mechanical performance, and material quality are tested. If any defects are detected, necessary corrections are made and it is ensured that the product is delivered to the customer at high standards.

Maintenance and Repair Services

Periodic Maintenance

Regular maintenance is required to extend the life of stainless steel mixers and maintain their performance. Periodic maintenance includes cleaning the inner and outer surfaces of the mixer, checking connection points, and replacing worn parts. This maintenance ensures that the mixer is long-lasting and operates efficiently.

Repair and Renovation

Damage or wear that may occur over time is remedied with professional repair and renovation services. ASLANLAR restores the mixer’s performance by offering fast and effective solutions with its expert team. During the repair process, it is ensured that all functions of the product are working correctly.

Stainless Steel Mixer Prices

Price Determination Criteria

The prices of stainless steel mixers are determined by factors such as the quality of the material used, the size of the mixer, design features, and additional services. By offering customized solutions suitable for the customer’s needs, the most appropriate price-performance ratio is ensured.

Economic Solutions

ASLANLAR aims to offer high quality at affordable prices. With cost-effective solutions, it produces stainless steel mixers that provide long-term satisfaction and bring economic benefits.

ASLANLAR’s Future Plans

Innovations and Projects

ASLANLAR continuously makes improvements in production processes by following the innovations in the sector. It aims to strengthen its leading position in the sector with new projects and technological investments. It expands its product portfolio with R&D studies and offers innovative solutions for customer needs.

Objectives in the Sector

ASLANLAR develops strategies to be more effective in the global market and to produce in international standards. The objectives in the sector include increasing quality and continuously improving customer satisfaction.

Conclusion

General Evaluation

ASLANLAR Paslanmaz Metal Sanayi offers quality, durability, and innovative solutions in stainless steel mixer production. It maintains its leading position in the sector with its 30 years of experience and customer-oriented approach. It is one of the reliable brands in the sector with its expert staff and high-standard products.

Advantages Offered by ASLANLAR

ASLANLAR has become a preferred brand in stainless steel mixer production with its high-quality standards, experienced staff, and customer satisfaction-oriented service approach. The durability and efficiency of its products provide long-term satisfaction to customers.

Stainless Steel Mixer Click for Detailed Information

How Long Do Stainless Steel Mixers Last?

Stainless steel mixers can be used for 20-30 years or longer with regular maintenance and repair.

How to Maintain Stainless Steel Mixers?

The maintenance of stainless steel mixers is done by regular cleaning, checking the connection points, and repairing possible damages. This extends the life of the mixer and maintains its performance.

How are the Prices of Stainless Steel Mixers Determined?

Prices are determined by the quality of the material used, the size of the mixer, and the design features. The most appropriate price-performance ratio is ensured by offering customer-specific solutions.

What are the Advantages of Stainless Steel Mixers?

Durability, hygiene, efficiency, and being environmentally friendly are the main advantages. In addition, their aesthetic appearance and recyclability are also important features.

How Can I Contact ASLANLAR?

To contact ASLANLAR, you can visit our website or contact us by phone. Our expert team is ready to offer you the most suitable solutions.