1. What is a Stainless Steel Powder Mixer?

Stainless steel powder mixers are machines made of stainless steel that enable the homogeneous mixing of powdered materials on an industrial scale. These devices have a wide range of uses in various sectors. Stainless steel ensures that the mixers are durable, corrosion-resistant, and hygienic. It is frequently preferred, especially in the pharmaceutical, chemical, and food industries.

The purpose of powder mixers is to turn different materials into a homogeneous mixture. These machines are long-lasting and comply with high hygiene standards because they are made of stainless steel. Bacterial buildup is prevented thanks to the stainless steel material, especially in environments requiring hygiene.

2. Working Principle of Powder Mixers

The basic working principle of powder mixers is to bring together different types of powders in the desired homogeneity. Mixers constantly move the materials with rotating blades, pallets, or helix mechanisms. In this way, undesirable situations such as clumping are prevented, and the same distribution is ensured at every point.

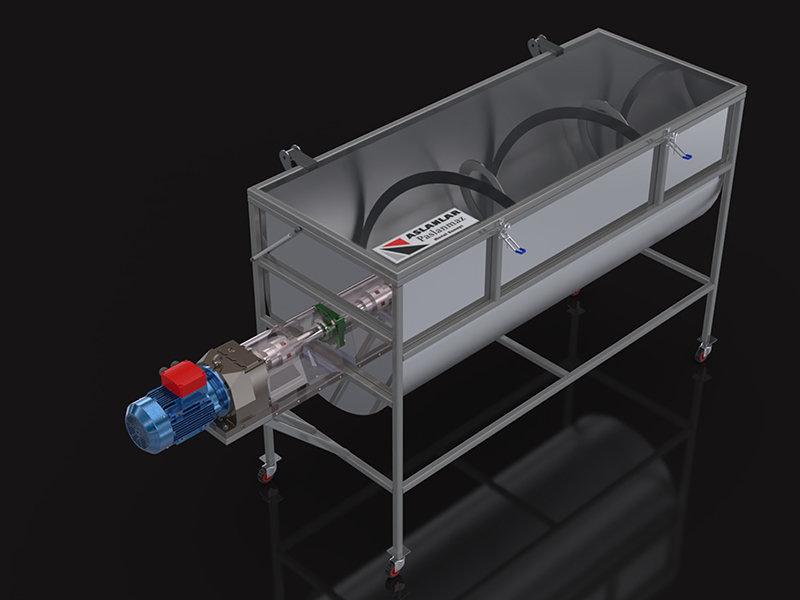

The main components of stainless steel powder mixers are:

- Mixing drum: The compartment where the materials are placed.

- Rotating mechanisms: Blades, pallets, or helices that constantly move the materials to ensure the homogeneity of the mixture.

- Motor and control panel: The mechanism used to adjust the speed and duration of the mixers.

These machines provide the ideal mix of different types of materials thanks to adjustable speed control.

3. Stainless Steel and Powder Mixing Technology

Stainless steel is the most suitable material for industrial mixers, especially due to its chemical reaction and corrosion-resistant structure. The use of stainless steel for powder mixers ensures that the mixture remains hygienic and free from contamination.

The main reasons for choosing stainless steel mixers are:

- Durability: Stainless steel does not wear out and maintains its structural integrity during long-term use.

- Corrosion resistance: Prevents deterioration of the material, especially when chemical mixtures are made.

- Hygienic properties: It has surfaces that are easy to clean and prevent bacterial buildup.

4. Types of Powder Mixers

Stainless steel powder mixers come in different types. Each is designed for different applications and needs:

- Horizontal Mixers: Suitable for larger volume mixtures and widely used in the food and agriculture sectors.

- Vertical Mixers: Saves space and is ideal for smaller scale mixtures.

- Double Helix Mixers: Mixes materials quickly and efficiently with two separate helix mechanisms.

- Conical Mixers: It works in a conical drum to provide a homogeneous mixture, and is especially suitable for mixing sensitive materials.

5. Use of Stainless Steel Powder Mixers in Industrial Sectors

Stainless steel powder mixers are widely used in many sectors. The main areas of use are:

- Chemical industry: Stainless steel mixers are required for mixing chemical powders because these machines are resistant to chemicals.

- Pharmaceutical industry: It is one of the sectors where hygiene is most important. Powder mixers are used during the production of medicines to ensure equal distribution of the ingredients.

- Food and agriculture sectors: Used for mixing flour, sugar and other powdered foodstuffs.

- Construction and building materials sector: Cement and other building materials are homogenized with the help of powder mixers.

6. Advantages of Stainless Steel Powder Mixers

Stainless steel powder mixers offer many advantages, as well as being widely preferred in many sectors. These advantages extend the life of the device, reduce operating costs, and meet hygiene requirements.

6.1 Durability of Stainless Steel

Stainless steel is far superior in terms of material durability. It does not rust, corrode, or resist external influences like other metals. Therefore, stainless steel powder mixers can operate smoothly for years. This durability reduces operating costs in the long run because it requires less maintenance and repair.

6.2 Corrosion Resistance

Stainless steel is highly resistant to corrosion. This feature is especially important in the chemical and food industries because these types of mixers are not damaged even when working with acidic or basic materials. Corrosion resistance ensures the preservation of product quality and prevents contamination.

6.3 Hygienic Design and Easy Cleanability

Stainless steel is an easy-to-clean and hygienic material. This feature provides a great advantage, especially in the food, pharmaceutical, and chemical industries. The smooth surface of the material prevents the accumulation of bacteria and germs. At the same time, it is also very easy to sterilize the mixers regularly.

6.4 Longevity

Powder mixers made of stainless steel material maintain their durability for years. Most of the time, these types of devices can be used for many years without requiring maintenance. This significantly reduces operating costs and extends the life of the devices.

7. Disadvantages of Stainless Steel Powder Mixers

Although stainless steel powder mixers have many advantages, they also have some disadvantages. By considering these disadvantages, you can choose the most suitable mixer for your business needs.

7.1 High Cost

Stainless steel is more expensive than other materials. Therefore, the cost of stainless steel powder mixers may also be higher. However, in the long run, durability and low maintenance costs offset this high initial cost.

7.2 Weight and Portability Issues

Stainless steel is a very heavy material. Therefore, large stainless steel powder mixers may be difficult to transport and relocate. Weight is an important factor to consider, especially for businesses that require mobile solutions.

8. Challenges Encountered in the Powder Mixing Process

The use of powder mixers also brings some challenges. To overcome these challenges, the right mixer selection and appropriate mixing techniques should be used.

8.1 Difficulty in Obtaining a Homogeneous Mixture

Mixing powders homogeneously is not always easy. Powders with different densities and sizes may not be distributed equally during mixing. To prevent this situation, the design of the mixers, mixing time and speed must be carefully adjusted.

8.2 Clumping Problem

Clumping is a common problem during the powder mixing process. This situation is more common, especially in materials with high humidity. To prevent clumping, it is necessary to ensure that the mixers work properly, control the humidity of the materials, and use anti-caking additives if necessary.

8.3 Optimizing the Mixing Time

The most suitable mixing time is different for each material. Long-term mixing processes can cause energy and time loss, while short-term mixing may not provide homogeneity. Therefore, the ideal mixing time required for each material should be determined and the machine settings should be adjusted accordingly.

9. Stainless Steel Powder Mixer Selection Criteria

Choosing the right stainless steel powder mixer increases the efficiency of operations and reduces costs. It is important to consider the following criteria when making a decision:

9.1 Capacity Requirement

It is very important to choose a mixer suitable for your business’s daily production capacity. While large-scale production facilities need high-capacity mixers, small-scale businesses may prefer lower-capacity models.

9.2 Mixing Speeds and Durations

Each powder material requires different mixing speeds and durations. The fact that the speed settings of the mixer you choose are flexible and user-friendly is a factor that directly affects the mixing quality.

9.3 Selection According to Purpose of Use

It may be necessary to mix different materials in different sectors. Mixers used in the food industry may be different from those in the chemical or pharmaceutical industries. Therefore, it is important to choose the most suitable mixer for the material you will use and your production process.

10. Maintenance and Cleaning of Stainless Steel Powder Mixers

Regular maintenance and cleaning are essential for stainless steel powder mixers to operate long-lasting and efficiently.

10.1 Importance of Regular Maintenance

Regular maintenance optimizes the performance of the mixer and prevents possible malfunctions. Routine operations such as lubricating moving parts and replacing worn parts ensure that the mixer runs smoothly.

10.2 Cleaning Methods and Hygiene Standards

Stainless steel mixers provide advantages in terms of hygiene. The smooth and easy-to-clean surfaces ensure that regular cleaning operations are fast and effective. Sterilization should also be performed frequently for mixers used in food and drug production.

10.3 Maintenance Tips for Long-Lasting Use

- Maintain the mixer according to the manufacturer’s instructions.

- Start cleaning immediately after the mixing process.

- Check and replace worn parts regularly.

- Do not neglect to lubricate the motor and mechanical parts.

11. Automation and Innovations in Powder Mixer Technologies

With the developments in technology, powder mixers have also started to be equipped with automation systems. These innovations ensure that production processes are more efficient and controllable.

11.1 Smart Systems and Digital Monitoring

Modern powder mixers are equipped with digital control panels and monitoring systems. These systems allow you to monitor every stage of the mixing process and intervene immediately when necessary. It also allows you to make long-term analyzes by recording process data.

11.2 Robotic Assisted Mixing Systems

Another reflection of automation technologies is robotic-assisted mixing systems. These systems minimize operator intervention and reduce the error rate. Robotic systems increase efficiency by eliminating human errors, especially in processes that require high precision.

11.3 Energy Efficiency and Environmentally Friendly Technologies

Modern mixers are turning to systems that consume less energy and are produced with environmentally friendly materials. This not only reduces production costs, but also contributes to environmental sustainability goals.

12. Pricing of Stainless Steel Powder Mixers

The prices of stainless steel powder mixers vary depending on many factors. Capacity, technology level and brand play an important role among these.

12.1 Factors Affecting Prices

- Capacity: High-capacity machines can be more expensive.

- Technology: Additional features such as automation and digital monitoring increase the cost.

- Material Quality: The quality of stainless steel and other materials used affect prices.

12.2 Models Suitable for Different Budgets

It is possible to choose suitable models according to the price performance ratio. While more economical options are available for small-scale businesses, large-scale manufacturers may prefer devices with higher features.

13. Safety Standards of Stainless Steel Powder Mixers

As with industrial machines, it is very important that stainless steel powder mixers comply with safety standards. Safety is a critical factor for both operators and the machine itself.

13.1 Occupational Safety Rules

Powder mixers can pose a risk in terms of occupational safety as they have mechanisms rotating at high speed. Therefore, workers must be ensured to use the machine correctly and comply with safety rules. It is mandatory to use protective equipment and have safety barriers in place.

13.2 Explosion Protection Systems

Some types of powders, especially chemical powders, can be flammable and explosive. In this case, it is necessary to use explosion prevention systems. For example, mixers that comply with ATEX standards are designed for explosive environments and ensure safety in such situations.

13.3 Fire Prevention Measures

Excessive heating or friction during the mixing of powders can create a fire risk. For this reason, stainless steel powder mixers must be equipped with fire prevention measures. The use of heat-resistant materials and temperature monitoring systems increase safety.

14. New Trends in Stainless Steel Powder Mixer Manufacturing

New technologies and sustainability concepts are coming to the fore in the manufacturing of stainless steel powder mixers. These innovations increase the efficiency of the machines while minimizing environmental impacts.

14.1 Sustainable and Environmentally Friendly Materials

The use of environmentally friendly and recyclable materials is of great importance in today’s industries. Stainless steel is an advantageous material in terms of environmental sustainability with its recyclable structure. In addition, an environmentally conscious approach is adopted in the production processes of mixers by using environmentally friendly coatings and energy-efficient motors.

14.2 High-Tech Materials and Coatings

Stainless steel mixers are reinforced with high-tech coatings to make them more resistant to wear and corrosion. In mixers designed specifically for chemical mixtures, these coatings ensure that the material can be used for a longer time.

14.3 Modular Design Advantages

Modular design has become a new trend in stainless steel powder mixers. Modular mixers provide both flexibility and reduce costs thanks to the addition and removal of different components according to need. For example, when the capacity is increased, modules can be added and expanded instead of completely replacing the machine.

15. Stainless Steel Powder Mixer Buying Guide

There are many factors to consider when purchasing a stainless steel powder mixer. The following points should be considered in order to make the right decision.

15.1 Tips for Choosing the Right Mixer

- Needs Analysis: First, determine the needs of your business. What materials are you working with? What is your daily production capacity? Choosing a mixer that suits your needs reduces costs in the long run.

- Capacity and Size: The capacity of the mixers should be determined according to your needs. High-capacity machines are preferred for large production lines, while compact mixers may be suitable for smaller-scale operations.

- Mixing Technology: Different mixing methods and technologies are available. Choosing the most suitable mixing technology for your needs will increase the efficiency of your production process.

15.2 Evaluation as a Long-Term Investment

Stainless steel mixers are generally considered as long-term investments as they are long-lasting and durable. The initial investment cost may be high, but the low maintenance costs and trouble-free operation for many years make these machines a profitable investment.

15.3 Guarantees and After-Sales Support

An important point to consider when purchasing a mixer is the warranty period and the quality of after-sales support. The support services provided by the manufacturer are of great importance in case of problems that may occur in the long run. In addition, the easy availability of spare parts supply and technical service services should also be considered when choosing a mixer.

Stainless steel powder mixers are one of the indispensable tools in industrial production. Their durable, hygienic and corrosion-resistant structures make them an ideal choice in many sectors such as food, medicine, chemistry and construction. Choosing the right mixer optimizes your business’s production process while reducing costs. With their long life and low maintenance costs, these machines stand out as a profitable investment in the long run.