Stainless steel profiles are among the indispensable parts of modern industrial and architectural designs. These profiles are used in a wide variety of fields due to their durability, aesthetic appearance and long-lasting structures. Stainless steel profile is frequently preferred in both the construction sector and daily life with its corrosion-resistant structure and environmentally friendly features.

What is Stainless Steel Profile?

Stainless steel profile is a long piece made of stainless steel, square, rectangular, round or specially shaped. These profiles are used especially in projects that require durability and contain all the advantages of stainless steel. Its preference in both indoor and outdoor applications is due to the material’s superior resistance to corrosion.

History and Development of Stainless Steel Profile

The first use of stainless steel profile dates back to the beginning of the 20th century. The invention of stainless steel was a revolutionary development in many industrial sectors, and profiles quickly became popular thanks to the advantages provided by this type of steel. Initially used only in industrial and military applications, these profiles have gradually spread to a wide range of uses, from architecture to the food industry.

Types of Stainless Steel Profile

Stainless steel profiles are produced in different shapes and sizes according to their usage areas and application requirements. The main types of stainless steel profiles are:

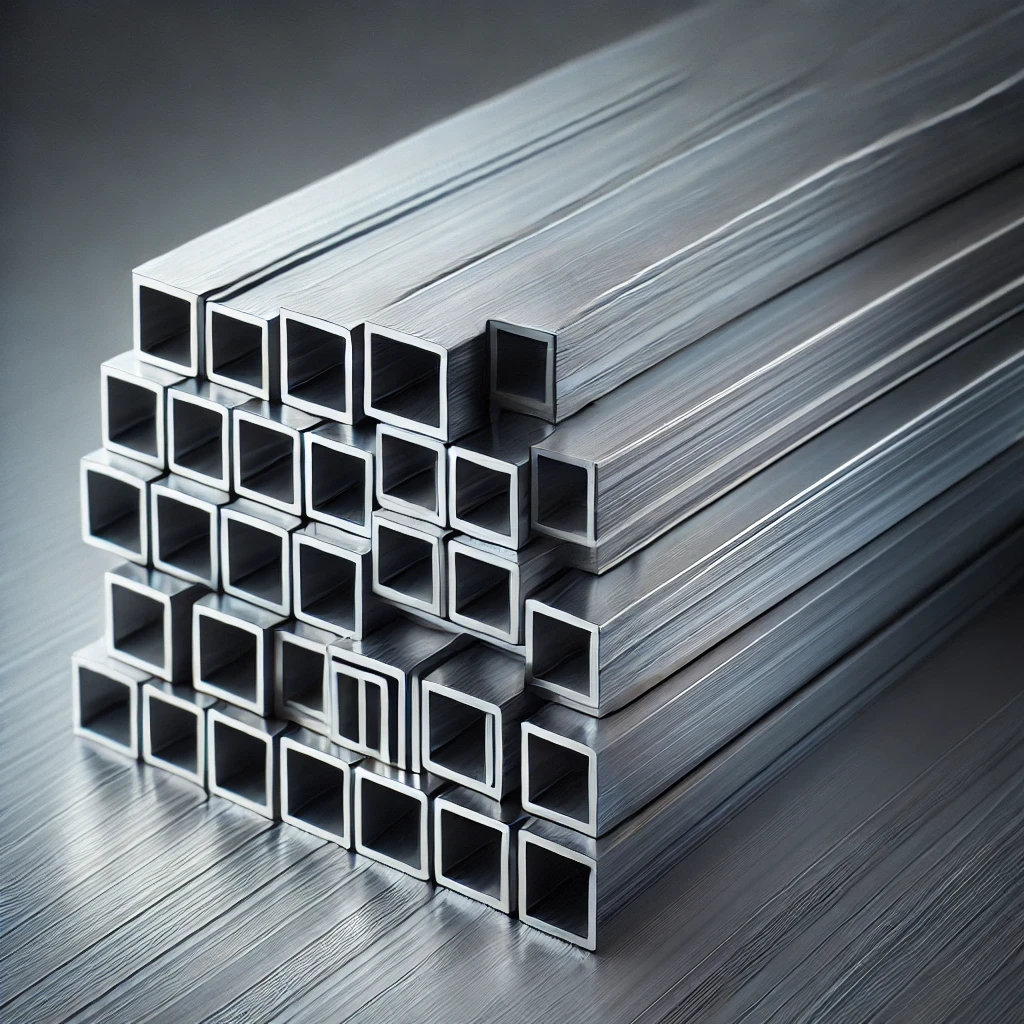

Square Stainless Steel Profile

Square stainless steel profiles are generally preferred in structural applications. Thanks to its aesthetic structure and durability, it is used in the skeleton structures and decorative elements of modern buildings.

Rectangular Stainless Steel Profile

Rectangular profiles are used in structures with high load-carrying capacity. This type of profile is generally preferred in construction projects, especially in the steel structures of bridges and large buildings.

Round Stainless Steel Profile

Round stainless steel profiles are used in areas such as pipelines, decorative elements and liquid transportation systems. Its aesthetic appearance and corrosion-resistant structure make these profiles a preferred option in liquid transportation lines.

Custom Design Stainless Steel Profiles

Special design profiles may be needed for some projects. These profiles are produced in special sizes and shapes according to the needs of the project. Especially in architectural projects, special designs add aesthetic value while guaranteeing durability.

Chemical Structure and Properties of Stainless Steel Profile

The main component of stainless steel profiles is chromium. This type of steel, which generally contains 10.5% or more chromium, shows high resistance to rust and oxidation. In addition, some alloys also contain elements such as nickel and molybdenum, which increase the material’s hardness, durability and rust resistance. This chemical composition ensures that the stainless steel profile can be used for many years without deformation.

Stainless Steel Profile Production Process

Stainless steel profile production involves melting raw materials at high temperature and shaping them into specific shapes. The desired profile shapes are obtained by using high-pressure machines during the processing of the steel. Quality control is very important during the production process, because the structural integrity of the material directly affects the service life and reliability of the profiles.

Usage Areas of Stainless Steel Profile

Stainless steel profile is used in a wide variety of sectors. The main usage areas are:

Construction and Architectural Use

Stainless steel profiles are one of the basic building blocks of modern structures. Thanks to its durability and aesthetic structure, it is used in various construction projects such as bridges, buildings and monumental structures. It is also frequently preferred for decorative purposes.

Usage in the Automotive Industry

Stainless steel profile is used in the automotive industry in the frame structure, exhaust systems and other mechanical components of vehicles. These materials are preferred to meet the safety, durability and long life expectations of vehicles.

Usage in the Food and Pharmaceutical Industries

Stainless steel profiles are preferred in the food and pharmaceutical industries, where hygiene requirements are high. Stainless material is easy to clean and can be used safely on surfaces that come into contact with food thanks to its corrosion-resistant structure.

Advantages of Stainless Steel Profile

The reasons for preferring stainless steel profile stem from its many advantages. Some of them are:

Corrosion Resistance

The biggest advantage of stainless steel profile is its superior resistance to rust. Especially when used outdoors and in areas exposed to moisture, deformation and rusting problems are not experienced for many years.

Aesthetic Appearance

The bright and clean appearance of stainless steel provides an aesthetic advantage, especially in architectural projects. The appearance of the profile can be further enhanced with surface treatment techniques.

Long-lasting and Easy to Maintain

Stainless steel profiles are long-lasting and do not require frequent maintenance. This provides cost advantage for users.

Stainless Steel Profile and Environmentally Friendly Production

Stainless steel profile production is an environmentally friendly process. Since stainless steel is a 100% recyclable material, it can be used over and over again without creating waste. The raw materials used in stainless steel profile production are obtained by methods that do not harm nature, and technologies that cause minimum harm to the environment are used during this production. In addition, the fact that stainless steel does not need to be replaced or renewed due to its long service life directly increases environmental sustainability.

Things to Consider When Choosing Stainless Steel Profile

There are some important factors to consider when choosing a stainless steel profile. Each project requires different needs and profiles suitable for these needs should be selected:

- Material Quality: The quality of the stainless steel profile is very important in terms of durability and long life. The chemical composition and production processes of the material affect the performance of the profile.

- Usage Area: The environment and conditions in which the profile will be used should be taken into consideration. For example, if it will be used outdoors, a stainless steel profile with high corrosion resistance should be preferred.

- Design and Dimensions: The required size and design may vary for each project. Therefore, the dimensions and shape of the profile to be used must be suitable for the needs of the project.

- Price Performance Ratio: The cost of the profile should be balanced with its quality and the advantages it offers. Affordable but quality products should be preferred.

Stainless Steel Profile Prices and Market Analysis

Stainless steel profile prices vary depending on many factors. The supply and demand balance in the market, the costs of raw materials and technological developments in production processes are among the basic factors affecting pricing. In addition, the quality, chemical composition, dimensions and special demands of the stainless steel profile are also important factors determining the price.

- Cost of Raw Materials: The prices of elements such as chromium, nickel and molybdenum, which are the raw materials of stainless steel, directly affect the price of the profile.

- Production Process and Costs: The technologies and machinery used in profile production are reflected in the total price of the profile.

- Demand and Market Dynamics: The demand for stainless steel profile in the construction and industrial sectors may increase prices. Price increases can be seen especially during the periods when large projects start.

How to Clean and Maintain Stainless Steel Profile?

Stainless steel profile is a material that is very easy to maintain and clean. Correct cleaning methods and regular maintenance extend the life of the stainless steel profile and preserve its bright appearance.

- Cleaning Frequency: Stainless steel profiles are exposed to environmental effects, especially when used outdoors. Therefore, it is recommended to clean them regularly.

- Cleaning Materials: Stainless steel profiles are generally cleaned with water and mild soaps. However, care should be taken when using chemical cleaners and abrasive substances should be avoided.

- Surface Treatments: Over time, dullness or small stains may occur on stainless steel profiles. In this case, the profile can be restored to its former brightness with surface polishing processes.

The Future of Stainless Steel Profile and New Technologies

Constantly developing technologies in stainless steel profile production show that the material will have an even wider usage area in the future. Innovations such as nanotechnology and advanced surface coating techniques improve the properties of stainless steel profiles and allow the production of more environmentally friendly and more durable profiles. It is expected that stainless steel will be preferred more, especially in the increase of green buildings and sustainability-oriented projects.

New technologies also reduce production costs and make stainless steel profiles more accessible. This will lead to their use in more sectors in the coming years.

Stainless steel profiles are indispensable materials in modern construction and industrial projects, offering great advantages both in terms of durability and aesthetics. With its corrosion resistance, long life and environmentally friendly structure, it will continue to be preferred in the coming years. This material, which is becoming widespread in both architectural projects and industrial applications, will continue to be an important component for a sustainable world.