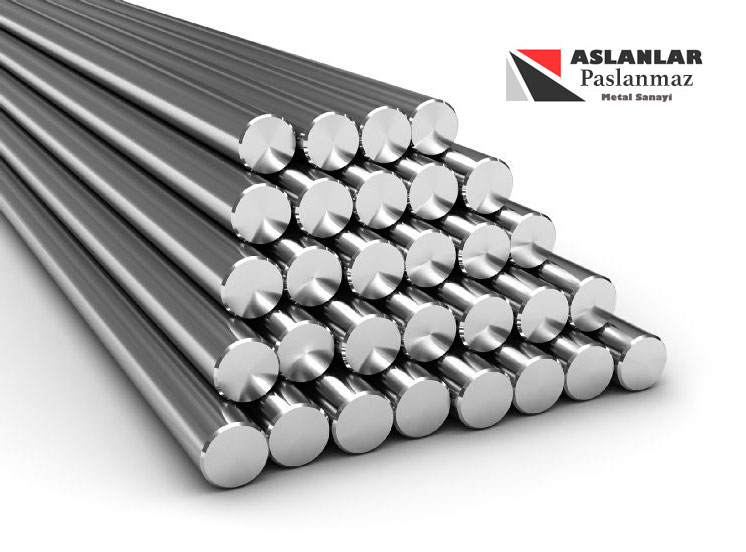

Stainless steel bar shafts are round cross-section steel bars with high corrosion resistance and strength. This material is often preferred in heavy industrial areas such as construction, automotive, machine manufacturing, and maritime. Stainless steel bar shafts are produced in various hardness levels and sizes, and can be used in different application areas.

General Features of Stainless Steel Bar Shaft

Stainless steel bar shafts are manufactured from high-quality steel alloys and offer various features.

Durability and Strength

One of the most prominent features of stainless steel bar shafts is their high strength. They can withstand heavy loads without deforming. Therefore, they are widely used in large industrial machinery and equipment.

Corrosion Resistance

Another important feature of stainless steel bar shafts is their resistance to corrosion. Thanks to their chromium-containing alloys, they can be used for a long time without experiencing problems such as rusting and abrasion.

Usage Areas of Stainless Steel Bar Shaft

Stainless steel bar shafts are versatile products that can be used in a wide range of applications.

Automotive Industry

In the automotive industry, stainless steel bar shafts are used in engine parts, shafts, and suspension systems. Their high strength and corrosion resistance make them an ideal material for this sector.

Machine Manufacturing

In machine manufacturing, stainless steel bar shafts are used in moving parts and machines requiring high performance. Their low maintenance needs and durability offer long-term use.

Maritime Sector

Ideal for corrosive environments such as seawater, 316 stainless steel bar shafts are preferred in the maritime sector for the production of ship parts and marine equipment.

Types of Stainless Steel Bar Shaft

Stainless steel bar shafts are produced in various types with different qualities and features.

304 Stainless Steel Bar Shaft

The 304 series is one of the most commonly used types of stainless steel. Suitable for general-purpose use, this shaft has high corrosion resistance and finds application in a wide range of areas.

316 Stainless Steel Bar Shaft

The 316 series is a type of stainless steel used especially in maritime and chemical environments. It exhibits excellent resistance to chemicals and salt water.

431 Stainless Steel Bar Shaft

The 431 series is a type of stainless steel used especially in applications requiring high strength and corrosion resistance. It is frequently preferred in the aerospace and defense industries.

Production Process of Stainless Steel Bar Shaft

The production of stainless steel bar shafts consists of several stages and determines the quality of the final product.

Raw Materials and Alloys

The main raw materials used in the production of stainless steel bar shafts are iron, chromium, nickel, and molybdenum. The proportions of these elements directly affect the properties and durability of the product.

Production Stages

The production stages include steps such as raw material melting, shaping, cooling, and surface treatment. Each of these processes is critical to ensure that the product meets quality standards.

Advantages of Stainless Steel Bar Shaft

Stainless steel bar shafts offer many advantages and therefore find a wide range of applications.

Long-Lasting

Stainless steel bar shafts are long-lasting due to their durability and resistance to abrasion. This allows for lower costs and more efficient use of products.

Easy Machinability

Stainless steel bar shafts are a suitable material for various industrial processes. Operations such as cutting, drilling, and welding can be performed easily.

How are Stainless Steel Bar Shaft Prices Determined?

Stainless steel bar shaft prices vary depending on the quality of the material used, its dimensions, and the production method. For example, special alloys such as the 316 series are more expensive than the standard 304 series because they offer more corrosion resistance.

What Should Be Considered When Purchasing Stainless Steel Bar Shaft?

The most important factor to consider when purchasing stainless steel bar shafts is to choose a material suitable for the intended use. In addition, the reliability of the manufacturer, product certificates, and quality standards should be taken into account.

Stainless Steel Bar Shaft and Maintenance

Stainless steel bar shafts generally require low maintenance. However, regular cleaning and storage in appropriate conditions extend the product’s life and improve its performance. It is recommended to avoid using abrasive chemicals during cleaning.

The Future of Stainless Steel Bar Shaft

Innovations in stainless steel technology will ensure that stainless steel bar shafts become more durable and environmentally friendly in the future. Recyclable materials and sustainable production techniques will shape the future of the stainless steel industry.

Stainless steel bar shafts are ideal materials for industrial applications. They are preferred in many sectors due to their durability, corrosion resistance, and long life. Whether it is automotive or machine manufacturing, stainless steel bar shafts are an indispensable part of industrial processes.