The safe storage and transportation of water, liquids, chemicals, food and more is a critical need for many industries and businesses. To meet this need, stainless steel tanks or stainless steel tanks provide an excellent storage solution. In this article, let’s examine what stainless steel tanks are, how they are manufactured, the state of production in Turkey, their usage areas, and a health comparison with plastic tanks.

What is a Stainless Steel Tank?

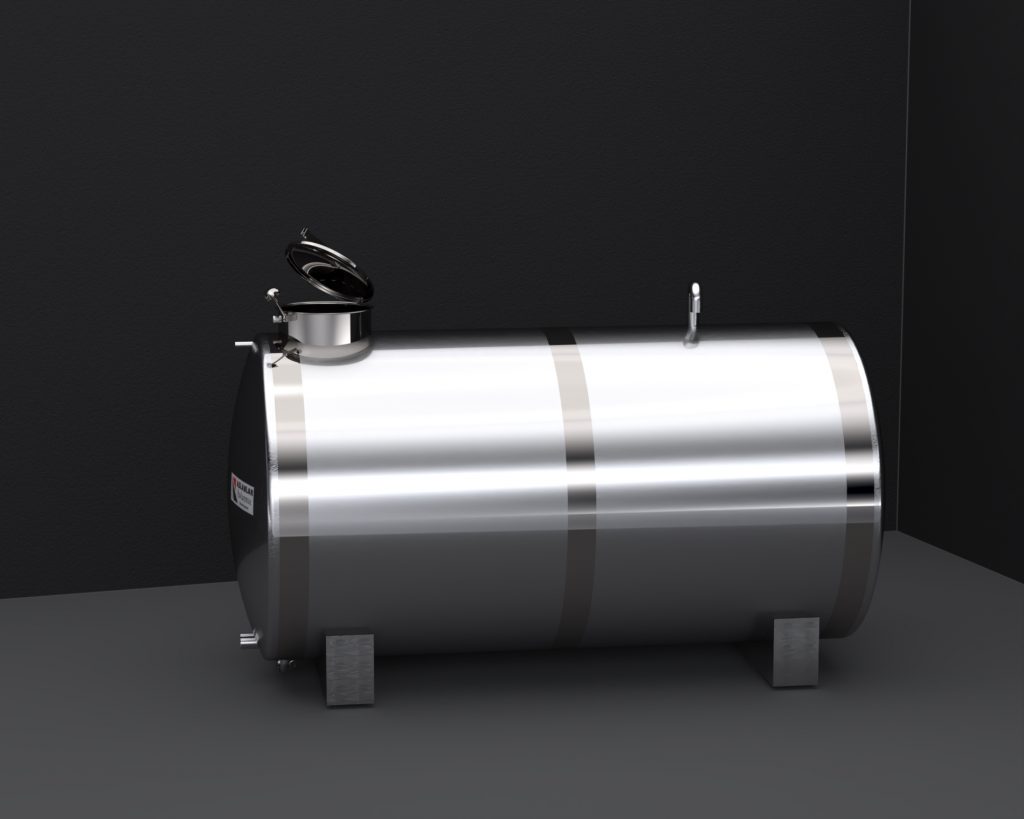

A stainless steel tank or stainless steel tank is a storage solution used to safely store water, liquids, chemicals, food and other substances. They are made of stainless steel, and this type of steel is extremely resistant to corrosion. Therefore, stainless steel tanks are ideal for maintaining the quality and safety of the substance they contain.

Production of Stainless Steel Tanks

Stainless steel tanks are manufactured by cutting, shaping, and welding stainless steel sheets. Production stages include:

Sheet Cutting: Stainless steel sheets are cut to the desired dimensions.

Shaping: The cut sheets are bent and shaped into the desired shape of the tank or tank.

Welding: Shaped parts are joined using special welding techniques.

Coating and Surface Treatment: The outer surface of the tanks is coated and given the desired aesthetic appearance.

Testing and Approval: Each tank is subjected to leak and durability tests and approved.

Production of Stainless Steel Tanks in Turkey

Turkey plays an important role in the production of stainless steel tanks. This production is generally concentrated in large industrial areas and port cities. Cities such as Istanbul, Izmir, and Bursa are centers of stainless steel tank production. Turkish manufacturers offer high-quality stainless steel tanks at competitive prices both in the domestic market and in the international arena.

Usage Areas of Stainless Steel Tanks

Stainless steel tanks are used for a number of industries and applications. Here are some examples:

Chemical Industry: They are ideal for the safe storage of chemicals.

Food Industry: They are hygienic and safe for storing food.

Water Treatment Plants: Used for storing and distributing clean water.

Oil and Gas Industry: They are preferred for storing and transporting petroleum products.

Agriculture: Used to store water and fertilizer in the agricultural sector.

Features of Industrial Type Stainless Steel Tanks

Industrial type stainless steel tanks should have the following features:

Durability: It must be resistant to chemical effects, impacts and high temperatures.

Hygiene: It must comply with hygiene standards for the food and pharmaceutical industries.

Leak-proof: It must be equipped with leak-proof and safety measures.

Suitable Capacity: It must have a capacity suitable for the need.

Comparison of Plastic and Stainless Steel Tanks in Terms of Water and Food Storage

Plastic tanks can be useful in certain applications, but stainless steel tanks are more commonly preferred for storing food and drinking water. Because stainless steel tanks meet hygienic requirements and are an ideal material for maintaining the quality of liquids. Plastic tanks may not be resistant to some chemicals and may crack over time.

Stainless steel tanks offer reliable storage solutions for many industries. Countries such as Turkey are leaders in the production of high-quality stainless steel tanks, and these tanks are indispensable for the safe and sound storage of liquids. Although plastic tanks continue to be used in some applications, stainless steel tanks are a better option, especially for water and food storage.