Stainless Steel | Properties, Types, and Applications

Stainless Steel | Properties, Types, and Applications

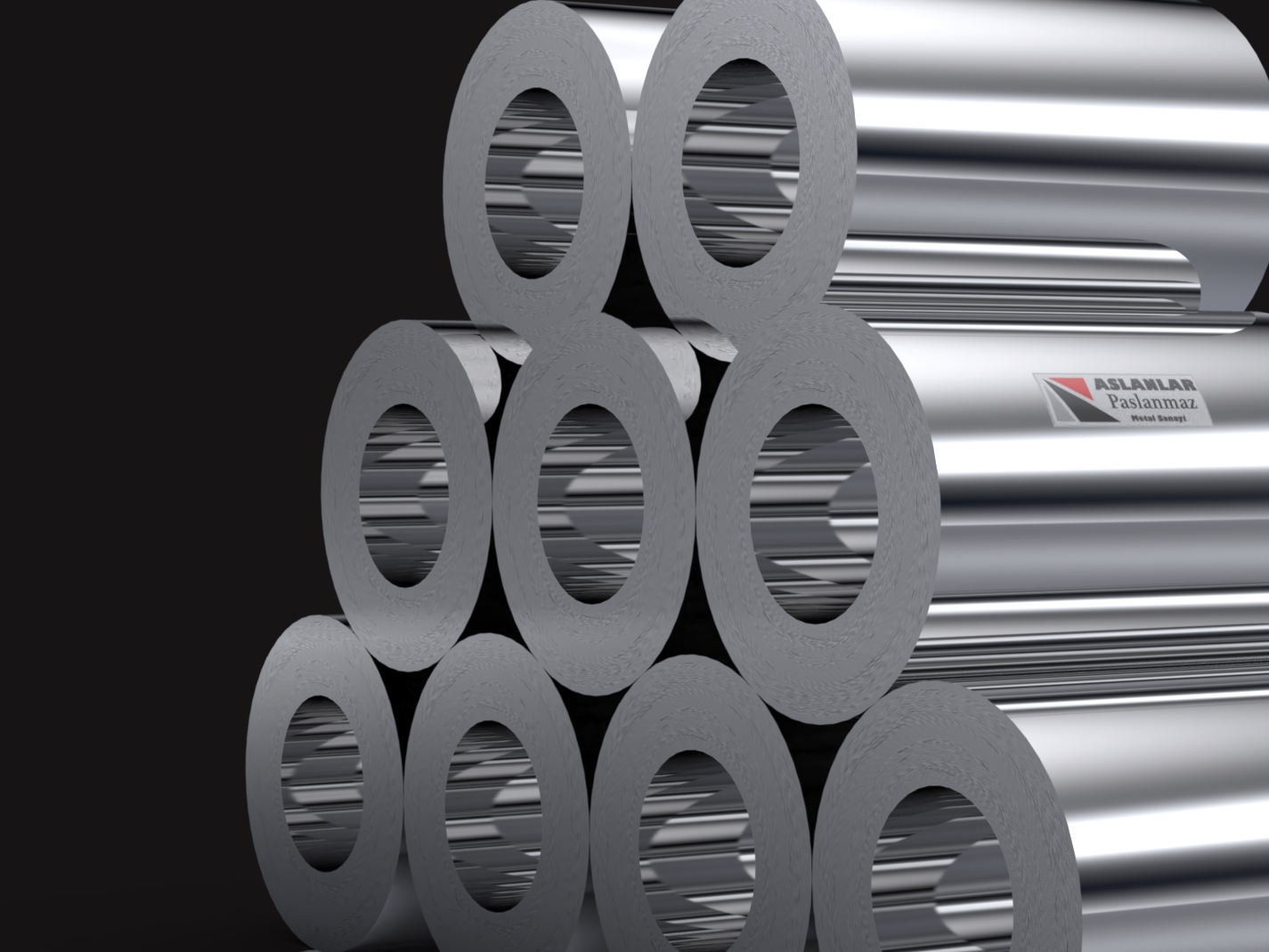

1. What is Stainless Steel Sheet?

Stainless steel sheet is a type of steel that is resistant to rust, produced by combining iron, chromium, and other alloys. The most important element it contains, chromium (Cr), increases corrosion resistance by forming a protective oxide layer on the surface of the material.

Stainless steel sheets are widely used in the food, automotive, construction, chemical, maritime, and many other industries.

2. Technical Specifications of Stainless Steel Sheet

The basic properties of stainless steel sheets are as follows:

- Chemical Composition: Contains a minimum of 10.5% chromium, nickel, molybdenum, and other alloys.

- Corrosion Resistance: Stainless and corrosion-resistant thanks to its high chromium content.

- Mechanical Durability: Offers high strength and impact resistance.

- Workability: Weldable and easily shaped.

3. Types of Stainless Steel Sheet

There are different types of stainless steel sheets for different applications:

- 304 Stainless Steel Sheet: The most commonly used type, preferred in food and hygienic areas.

- 316 Stainless Steel Sheet: More resistant to seawater and chemicals.

- 430 Stainless Steel Sheet: Frequently used in kitchen equipment due to its magnetic property.

4. Stainless Steel Sheet Production Process

The production of stainless steel sheet consists of the following steps:

- Raw Material Selection: Elements such as iron, chromium, and nickel are combined.

- Melting and Alloying: Alloy is formed by melting at high temperature.

- Casting: Poured into thin sheets and prepared for rolling.

- Cold or Hot Rolling: Undergoes different rolling processes depending on its thickness.

- Polishing and Surface Treatments: Finally, the surface is smoothed.

5. Usage Areas of Stainless Steel Sheet

Stainless steel sheet is used in many sectors:

- Industry: In the production of machinery and equipment

- Automotive: In vehicle bodies and exhaust systems

- Construction: In facade coatings, railings, and roofing systems

- Food: In kitchen utensils, industrial ovens, and processing machines

- Medicine: In surgical instruments and hygienic surfaces Advantages and Disadvantages of Stainless Steel Sheet

Advantages:

High durability and long life

Excellent resistance to corrosion

Easy to clean and hygienic

Disadvantages:

More expensive than carbon steel

May require special welding techniques

7. Things to Consider When Choosing Stainless Steel Sheet

The following factors should be considered when purchasing stainless steel sheet:

- Selection of appropriate quality (304, 316, etc.) for the area of use

- Determining the thickness according to the need

- Surface coating (matte, glossy, patterned, etc.)

8. Stainless Steel Sheet Maintenance and Cleaning

Follow these steps to extend the life of stainless steel sheet:

Regular cleaning with a soft cloth

Using non-abrasive detergents

Removing salt and chemical residues

9. Environmental Effects of Stainless Steel Sheet

It is a 100% recyclable material.

It is supported by environmentally friendly production processes.

11. Alternatives to Stainless Steel Sheet

The following alternatives can be used instead of stainless steel sheet:

- Galvanized sheet: Low cost but less resistant to rust.

- Aluminum: Lightweight but its strength is lower than stainless steel.

12. Frequently Asked Questions (FAQ)

Does stainless steel sheet rust?

No, but stains may form on the surface if exposed to misuse and harsh chemicals.

How to clean stainless steel sheet?

It should be cleaned by wiping with a soft cloth and stainless steel cleaners.

Is stainless steel sheet magnetized?

Some types (such as 430) are magnetic, but 304 and 316 are not.

For More Detailed Information, Click Here.