Stainless steel mixers are one of the most commonly used equipment in industrial production processes. Thanks to their high durability, hygienic properties, and resistance to corrosion, they are preferred in many sectors, especially food, chemical, pharmaceutical, and cosmetics. In this article, we will provide a comprehensive guide on the uses, selection criteria, and advantages of stainless steel mixers.

What is Stainless Steel?

Stainless steel is a steel alloy containing at least 10.5% chromium. This alloy forms a corrosion-resistant layer on the surface of the steel, protecting it from external factors such as corrosion and oxidation. Stainless steel is preferred in many industries because it is a long-lasting, durable, and easy-to-clean material.

Advantages of Stainless Steel

· Corrosion Resistance: It is highly resistant to corrosion due to its high chromium content.

· Hygienic Properties: Its smooth surface prevents bacteria accumulation.

· Durability: It is resistant to mechanical damage and has a long service life.

Mixer Types

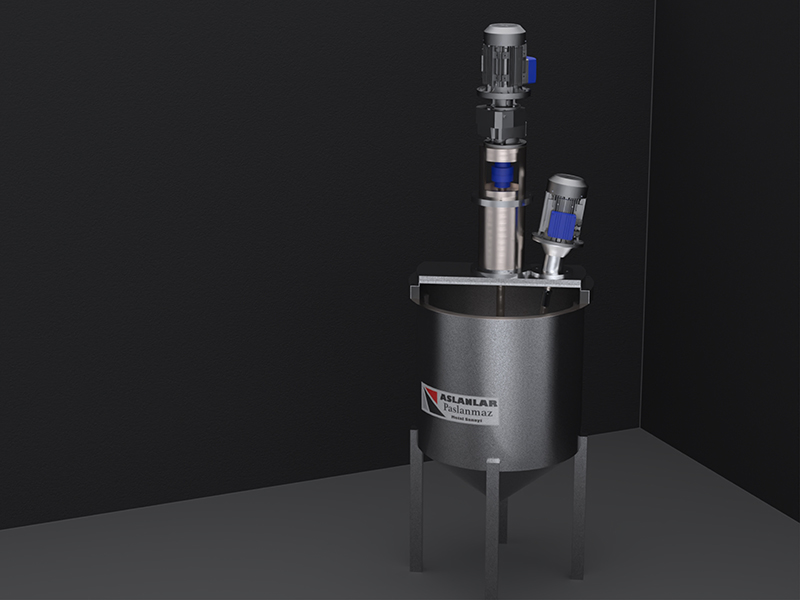

Mixers used in industrial processes vary according to their functions and applications. Stainless steel mixers are used particularly in sectors where hygiene is at the forefront. The main types of mixers are:

· Propeller Mixers: Suitable for high-speed and low-viscosity liquids.

· Double Shaft Mixers: Used for high-viscosity substances.

· Ribbon Mixers: Ideal for obtaining homogeneous mixtures.

Usage Areas of Stainless Steel Mixers

Food Industry

Hygiene is one of the most important elements in the food industry. Stainless steel mixers are used for mixing, kneading, and homogenizing food products. They are indispensable, especially in the production of dairy products, fruit juice, and bakery products.

Chemical Industry

Most of the substances used in the chemical industry have corrosive or reactive properties. Therefore, stainless steel mixers ensure the safe processing of these substances.

Pharmaceutical Industry

In pharmaceutical production, it is very important that mixtures remain pure and hygienic. Stainless steel mixers play a critical role in mixing pharmaceutical substances in the correct proportions and reducing the risk of contamination.

Cosmetics and Cleaning Products

Obtaining homogeneous mixtures is of great importance in the production of cosmetics and cleaning products. Stainless steel mixers are widely used in the production process of these products.

Agriculture and Livestock Sector

Stainless steel mixers are also preferred in feed production and in the preparation of various agricultural mixtures.

Things to Consider When Choosing a Stainless Steel Mixer

There are some important factors to consider when choosing a stainless steel mixer:

Capacity and Volume

Choosing a mixer with a capacity suitable for the production process is very important. The correct capacity should be determined according to the required production quantity.

Mixing Speed and Power

Mixing different substances requires different speeds and power. A mixer with suitable speed and power should be preferred according to the substance to be mixed.

Durability and Corrosion Resistance

The quality of stainless steel ensures the long life of the mixer. Durability is very important, especially in processes where chemicals are mixed.

Energy Efficiency

Energy-saving mixers both reduce costs and cause less damage to the environment.

Ease of Cleaning and Maintenance

The mixer should be easy to clean. Cleaning procedures are vital in sectors where hygiene is important.

Advantages of Stainless Steel Mixers

Stainless steel mixers have become indispensable in many sectors thanks to the advantages they offer:

· Hygiene: Stainless steel provides a hygienic production environment by preventing the formation of bacteria.

· Durability: It is long-lasting and resistant to difficult conditions.

· Corrosion Resistance: It is resistant to chemical substances and is therefore preferred in many industries.

Maintenance and Cleaning of Stainless Steel Mixers

Regular maintenance and cleaning are essential for stainless steel mixers to be long-lasting and efficient. It is quite easy to clean, but certain procedures should be followed to prevent the accumulation of chemical residues.

Prices and Cost Analysis of Stainless Steel Mixers

The price of stainless steel mixers may vary depending on factors such as capacity, brand, and mixer type. In the long term, considering the durability and low maintenance costs of these mixers, it is seen that it is a profitable investment even if the initial cost is higher.

Mixer Manufacturers and Suppliers

Mixers purchased from the right manufacturer and supplier provide long-lasting use. A reliable supplier offers important services such as warranty period, after-sales support, and spare parts supply.

Stainless steel mixers are critical for many industries. Their advantages such as hygiene, durability, and corrosion resistance make these mixers indispensable. Choosing a mixer suitable for your needs will optimize production processes while reducing costs.

Mixers are used in a wide variety of areas in different industries. Take a look at this guide to examine the factors affecting the prices of Stainless Steel Tanks.