MIXERS

- posted by: İsmail YILDIZ

- No Comments

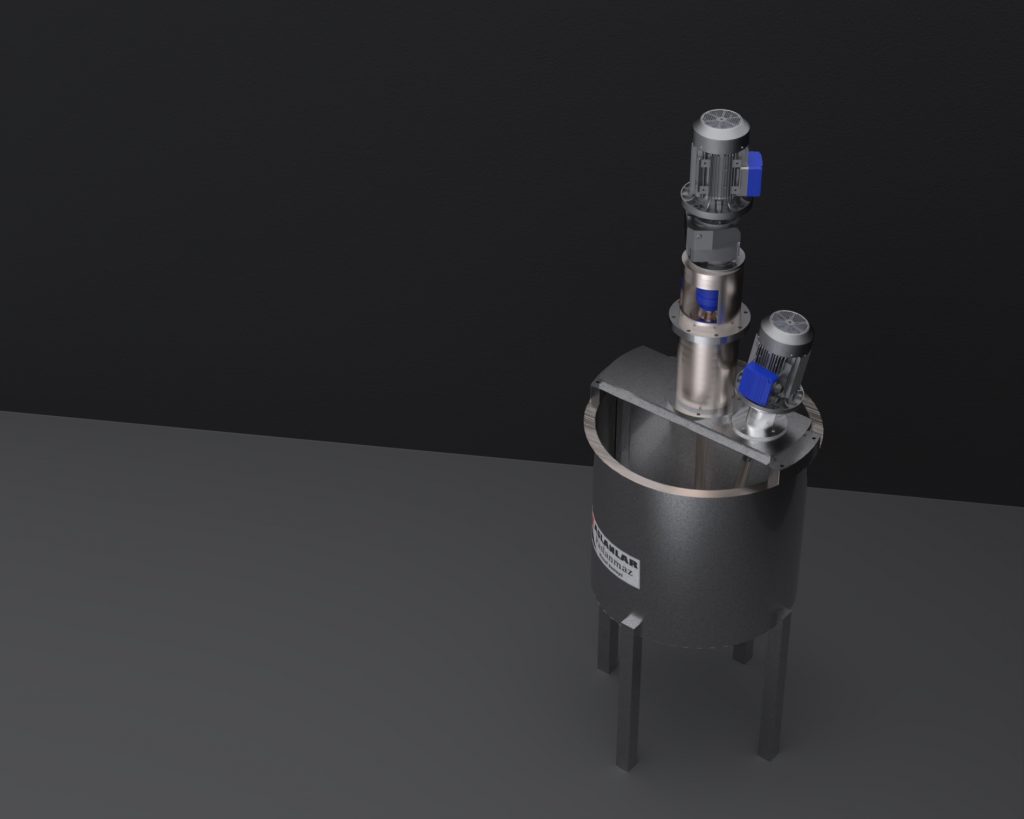

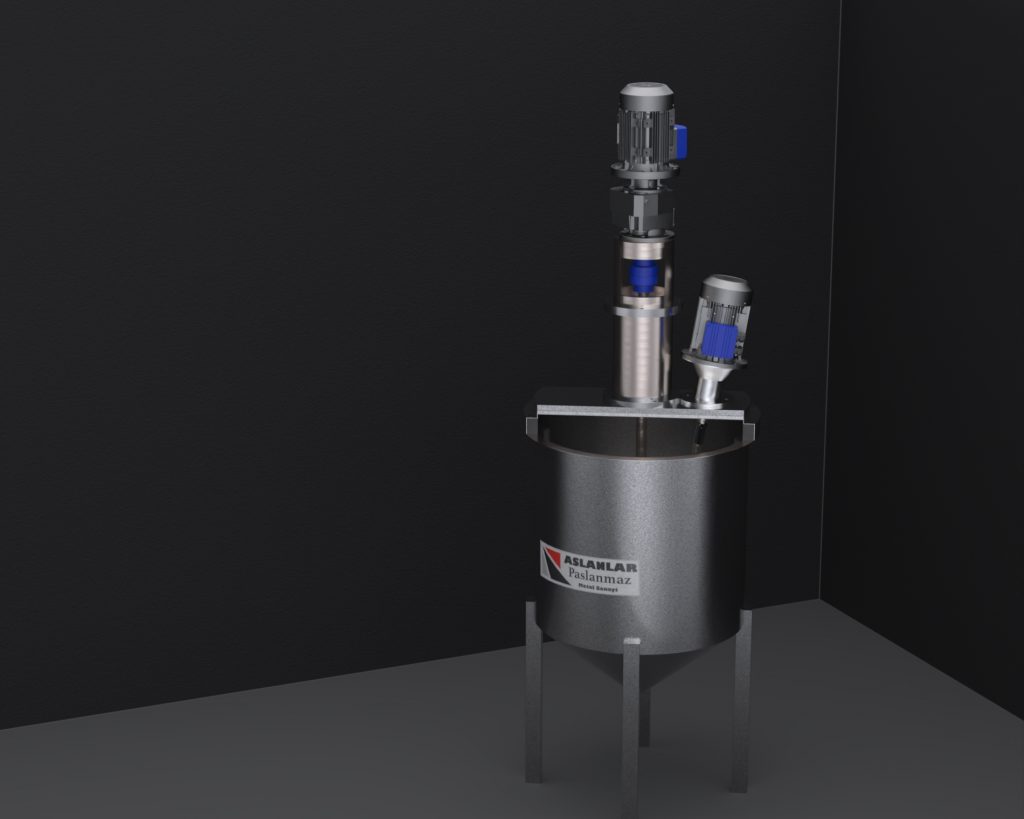

Mixers are indispensable equipment for industrial production, manufactured from durable and corrosion-resistant stainless steel material. Mixers are used in many sectors such as food, chemical, pharmaceutical, cosmetics and more, for homogeneous mixing of liquid and solid substances of different viscosities.

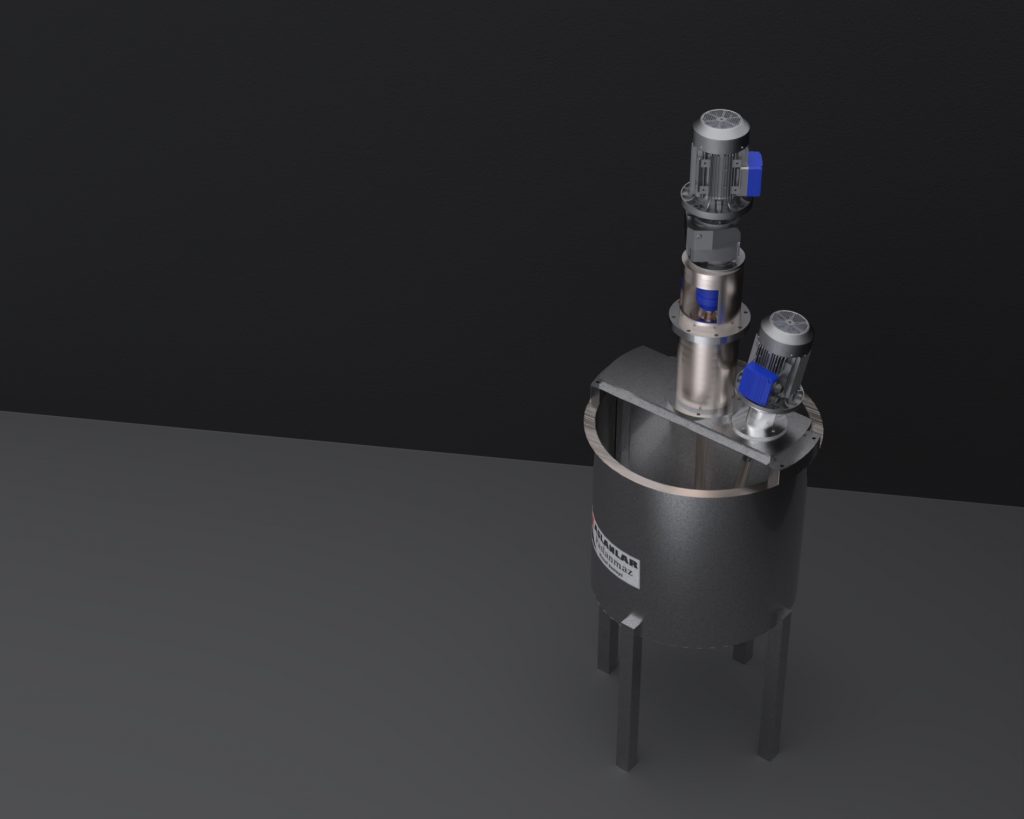

Stainless steel is an important factor in the preference of stainless steel mixers with its hygienic structure and long life. Thanks to this material, the formation of bacteria and microorganisms on the surface of the equipment is prevented, thus increasing the quality and safety of the products.

Mixers can be customized in various sizes and designs to suit production processes. These devices, which can be integrated with automatic and semi-automatic control systems, offer ideal solutions to increase efficiency and optimize production processes.

In addition, stainless steel mixers are not only used for mixing; it is also effective in processes such as crushing small particles, providing dispersion and increasing homogeneity. Thanks to electric motors, they provide precise control with different speed and power settings.

With its durability and easy-to-clean structure, these mixers prevent bacterial growth and ensure the protection of hygiene standards in the food and pharmaceutical industries. Stainless steel mixers, which can be safely used in harsh environments such as industrial waste treatment, energy, and petrochemicals, support production quality and continuity.

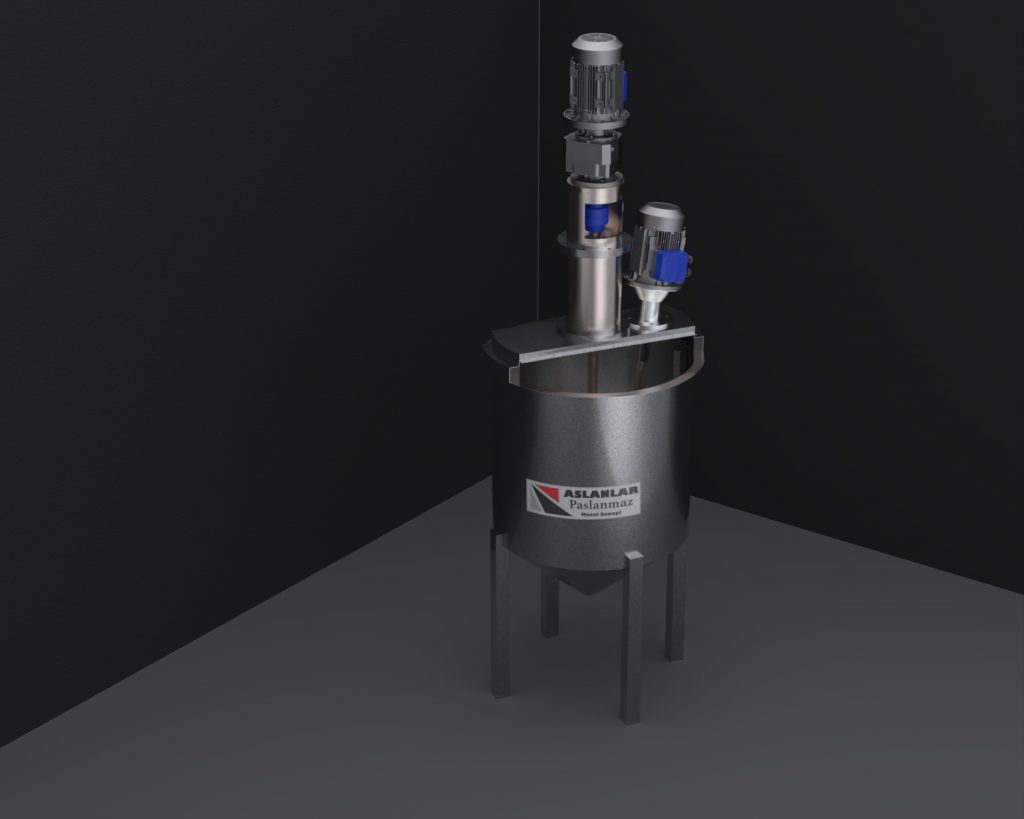

In every field where production capacity and product quality need to be increased, a correctly selected stainless steel mixer reduces costs in the long term and ensures that processes proceed in a more controlled manner. While the performance of mixers is increased with technological developments, energy consumption is also optimized.

As a result, stainless steel mixers are an indispensable tool in terms of durability, hygiene and efficiency for companies that want to produce to high standards. The right mixer selection directly affects product quality and plays a critical role in the success of production processes.

Usage Areas and Examples

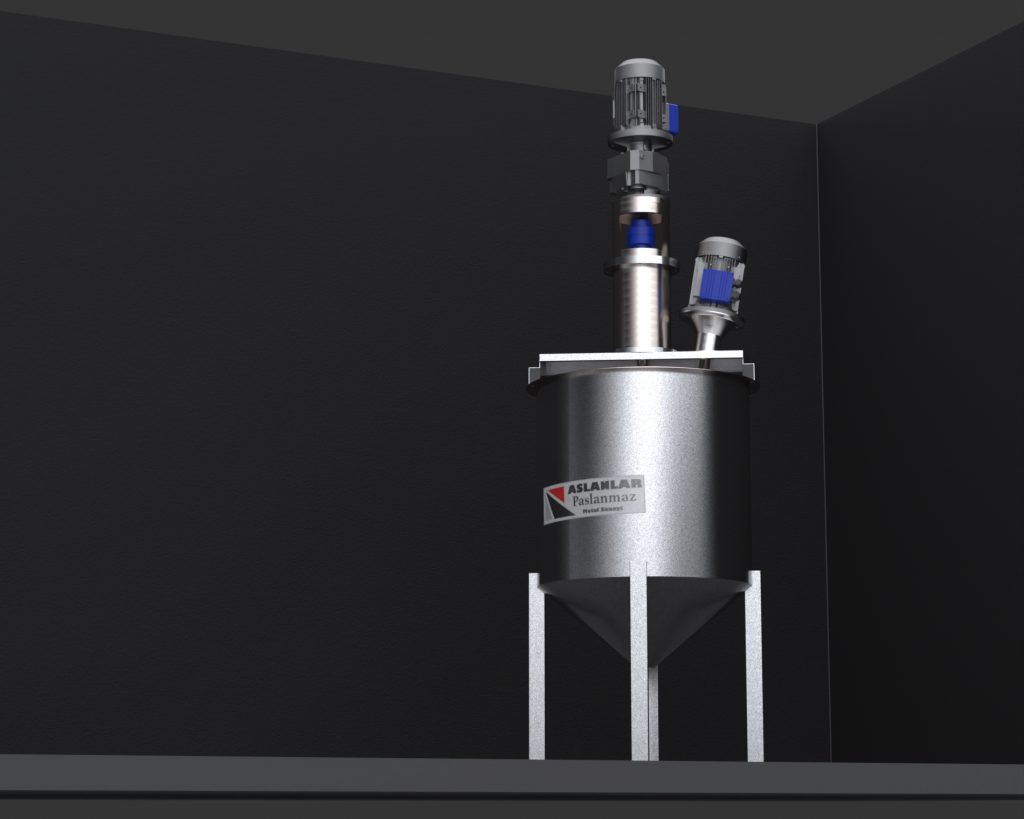

- Food Industry: Industrial type stainless steel mixers are used for mixing, homogenizing and emulsifying a wide variety of materials in food production. For example; They are used in the production of mayonnaise, ketchup, sauce, yogurt, cake, biscuits and chocolate.

- Chemical Industry: The chemical industry uses industrial type stainless steel mixers in many different chemical processes. For example; production of polymers, petroleum refinery operations, production of paint, ink and other chemical products.

- Pharmaceutical Industry: It is used for mixing, homogenizing and emulsifying pharmaceutical ingredients. It also takes place in the production and packaging of medicines.

- Cosmetics Industry: They are used in the production of shampoo, conditioner, lotion, make-up materials, perfume and other cosmetic products.

- Water Treatment Industry: It is used in water disinfection and purification processes in water treatment processes.

Industrial type stainless steel mixers are widely used in industrial applications because they homogenize the mixture, save time and energy, increase product quality and increase production efficiency in production processes.