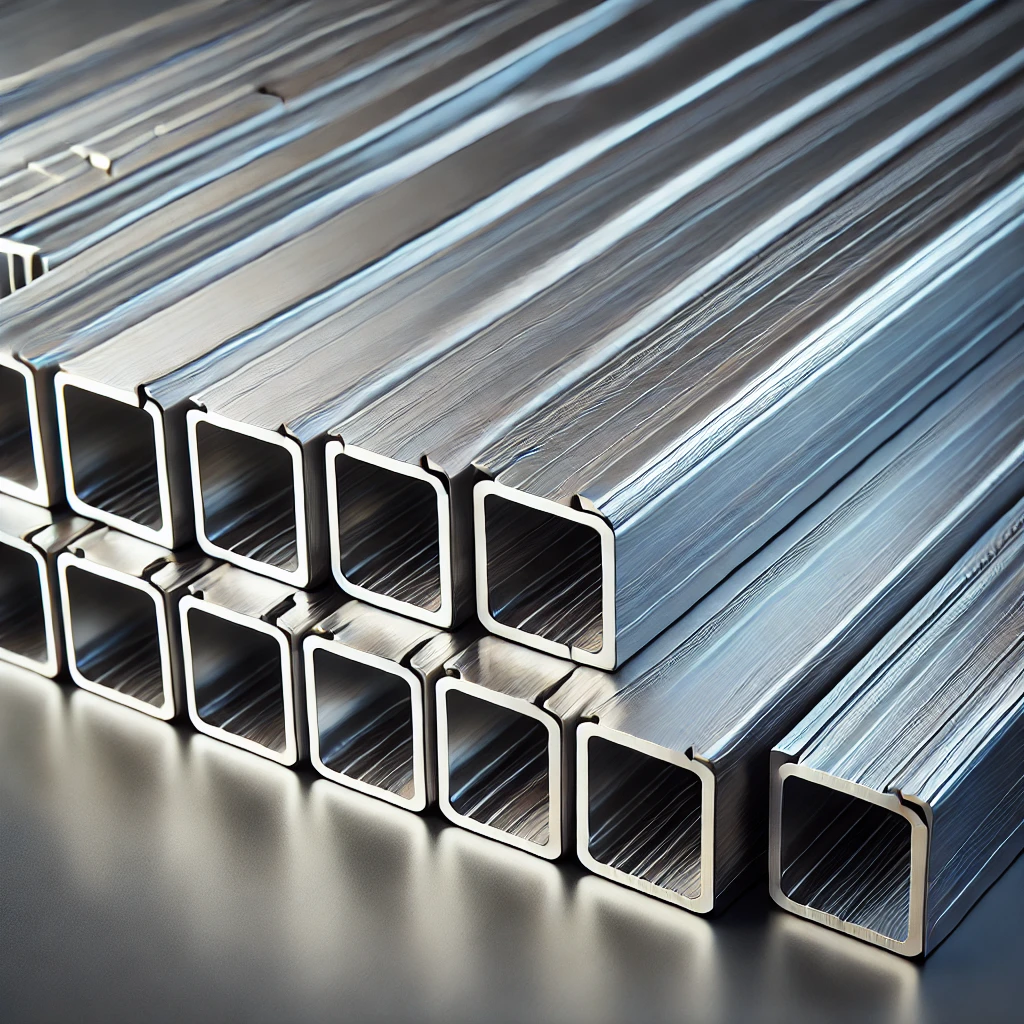

Stainless Steel Square: Discover Durability and Versatile Applications

Stainless steel square is a material used in many areas such as construction and industry, standing out with its durability and corrosion resistance. The square cross-sectional form of stainless steel is preferred in various sectors due to its robustness and aesthetic appearance. In this article, you will find answers to many questions such as what is stainless steel square, what are its properties, how is it produced, and in which areas is it used.

What is Stainless Steel Square?

Stainless steel square is a square-shaped steel material made of stainless steel. This type of steel, known for its corrosion-resistant structure, also attracts attention with its strength, durability, and aesthetic appearance. Stainless steel square is resistant to rust due to the chromium it contains and stands out as a long-lasting material.

Properties of Stainless Steel

Stainless steel has many superior properties. The most important of these is its resistance to corrosion. The chromium element it contains forms a protective layer on the surface of the steel, and this layer prevents the steel from rusting when it comes into contact with oxygen.

Corrosion Resistance

One of the most important advantages of stainless steel squares is their resistance to oxidation and corrosion. This feature makes stainless steel square indispensable, especially in outdoor applications and humid environments.

Durability and Strength

Stainless steel square is known for its high strength and durability. Thanks to these features, it is frequently preferred in areas such as construction and heavy industry.

High Temperature Resistance

Stainless steel square retains its structure even at high temperatures. This makes it an ideal material for industrial furnaces, engines, and machines exposed to high heat.

Aesthetic Appearance and Surface Quality

The shiny surface of stainless steel offers a stylish look, especially in decorative applications. Providing a smooth and clean surface allows stainless steel squares to be used in interior and exterior designs.

Types of Stainless Steel Square

Stainless steel square is produced in different types according to the quality and content of the steel. The most common stainless steel square types include 304, 316, and 430 steel types.

304 Stainless Steel Square

304 type stainless steel is the most commonly used type in stainless steel squares. This steel, which is preferred in general-purpose applications, is highly resistant to corrosion and has an excellent surface quality.

316 Stainless Steel Square

316 stainless steel is frequently preferred in the chemical and maritime sectors. Thanks to the molybdenum it contains, it shows superior resistance to corrosion even in chlorinated environments.

430 Stainless Steel Square

430 stainless steel has magnetic properties and is generally used for decorative purposes. Although its corrosion resistance is lower than 304 and 316, it gives successful results in aesthetic applications.

Stainless Steel Square Production Process

Stainless steel squares are shaped by going through certain production stages. Steps such as melting, casting, cutting, and surface treatments are followed in this process.

Melting and Casting Process

Stainless steel is melted at high temperatures and poured into certain molds. This process forms the basic form of stainless steel.

Cutting and Shaping Techniques

Stainless steel square is produced by cutting and shaping the steel plate. The cutting process is usually done with laser or plasma cutting techniques.

Surface Treatment Applications

In the final stages of the production process, surface treatments are applied to increase the aesthetic appearance of stainless steel. This process is done with various techniques such as polishing, matting, or brushing the stainless steel.

Usage Areas of Stainless Steel Square

Stainless steel square is widely used in many sectors. It is indispensable in areas such as construction, industry, and decoration with its durability and aesthetic appearance.

Construction and Building Sector

The construction sector is one of the areas where stainless steel squares are used the most. It is preferred as a durable and long-lasting material in structural elements, bridges, and facade claddings.

Machinery and Industrial Production

The use of stainless steel square in industrial machines is common. Thanks to its high strength and durability, it offers a long-lasting performance in machine parts and equipment.

Decoration and Interior Architecture

The shiny and smooth surface of stainless steel is ideal for decorative uses. It is frequently encountered in interior designs, furniture, and various decorative elements.

Food and Chemical Industry

Hygiene and corrosion resistance are of great importance in food processing and chemical industries. Stainless steel squares offer both a safe and durable solution in such environments.

Things to Consider When Choosing Stainless Steel Square

It is necessary to pay attention to some important factors when purchasing stainless steel square and using it in projects. These factors ensure that the material is long-lasting and suitable for the application area.

Quality Standards

It is very important to pay attention to quality standards when buying stainless steel square. Stainless steel must be produced in accordance with certain certificates and international standards. Quality documents provide information about the durability and performance of the material. For example, ASTM and EN standards provide reference about the corrosion resistance, hardness, and chemical composition of the material.

Suitability for the Application Area

Another factor to consider when choosing stainless steel square is its suitability for the application area. While 304 stainless steel is suitable for general purpose uses, 316 stainless steel should be preferred if it will be exposed to more aggressive environmental conditions (for example, areas in contact with seawater). Usage conditions and environmental conditions should be taken into consideration.

Stainless Steel Square Prices and Cost Factors

Stainless steel square prices vary depending on various factors. Pricing is shaped depending on the quality of the material, the production process, and the amount of use in the project.

Pricing According to Steel Quality

Stainless steel quality has a great impact on prices. 304 quality stainless steel is more affordable, while 316 quality stainless steel is more expensive due to the molybdenum it contains. At the same time, special alloys or additional chemical compositions may cause prices to increase.

Production Method and Price Effect

Production processes are also an important factor affecting the price of stainless steel squares. Steps such as cutting, shaping, and surface treatment can increase the cost. For example, special surface treatments or precision cutting techniques (such as laser cutting) may be more costly.

Stainless Steel Square Maintenance and Cleaning Tips

Regular maintenance and cleaning are required for stainless steel squares to be long-lasting. Certain cleaning techniques should be followed to maintain the aesthetic appearance of stainless steel and increase its resistance to corrosion.

Regular Cleaning:

Stainless square is a square-shaped material made of stainless steel. It is widely used in construction, machine manufacturing, decoration, and the food industry.316 grade stainless steel is the most durable, especially in environments requiring corrosion resistance (e.g., areas in contact with seawater).Should be cleaned regularly with a soft cloth and mild soapy water. Abrasive chemicals should not be used.Stainless steel is corrosion-resistant, while carbon steel is more cost-effective but not resistant to rust.Quality certificates should be considered to determine the supplier’s reliability and whether the product complies with international standards.Cost varies depending on the steel grade and production method. Generally, 304 grade stainless steel is one of the most affordable options.