Dust Mixers

Dust Mixers

High Performance in Industry: Stainless Steel Powder Mixers

In the industry, equipment used in the production and processing of various products is of vital importance. You can examine the importance, types, advantages, and application areas of stainless steel powder mixers, which are widely used in the industrial sector, in detail below.

Stainless Steel Powder Mixer

What is a Stainless Steel Powder Mixer?

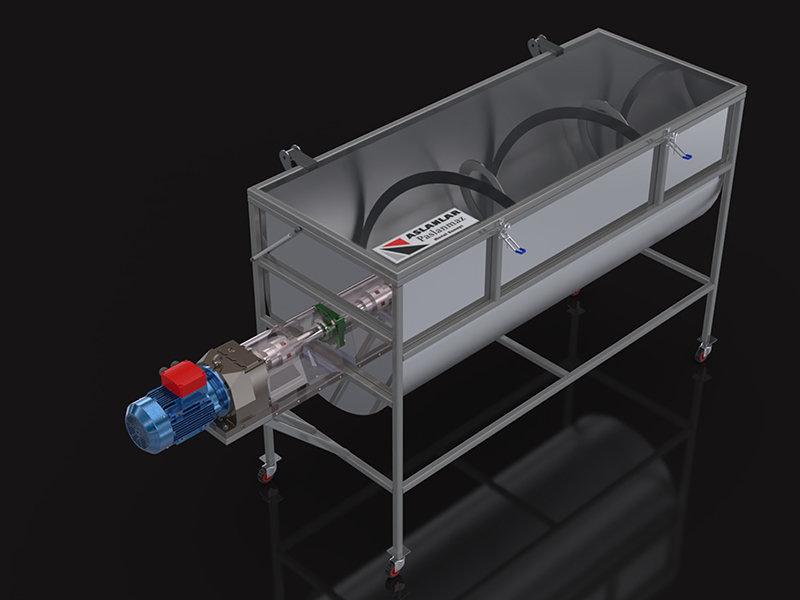

Stainless steel powder mixers are tools designed to homogenize powder substances and other solid substances. These machines, usually made of AISI 304 or 316 quality stainless steel, exhibit high resistance to corrosion and ensure hygienic production standards.

Types and Advantages

Stainless steel powder mixers can be found in different designs according to production needs:

Stainless Steel Powder Mixer

- Horizontal Mixers (Ribbon Blender)

- Vertical Mixers

- Conical Mixers

- Rotary Drum Mixers

The main advantages provided by these equipment are:

- Achieving homogeneous mixture with high mixing efficiency.

- Saving energy and time thanks to short mixing times.

- Easy to clean surfaces and hygienic production environment.

- Long service life against corrosion and wear.

Application Areas and Sectors

Stainless steel powder mixers; It is widely used in many industrial fields such as food, medicine, chemistry, cosmetics and construction.

- Food Industry: Homogenization of flour, powdered sugar, spices, coffee mixtures and food supplements.

- Pharmaceutical Industry: Mixing powder drug raw materials and granules in precise proportions.

- Chemical Industry: Blending detergents, powder paints, plastic granules and chemical additives.

Cross-Sectoral Use and Technology

Stainless steel powder mixers offer a flexible usage opportunity between different industries. For example, a mixer produced in accordance with food industry standards can be safely used in the pharmaceutical or sensitive chemical industry since it requires high hygiene.

This technology, which increases efficiency in the industry and guarantees product quality, plays a critical role in production processes and makes a great contribution to the success of industrial enterprises.