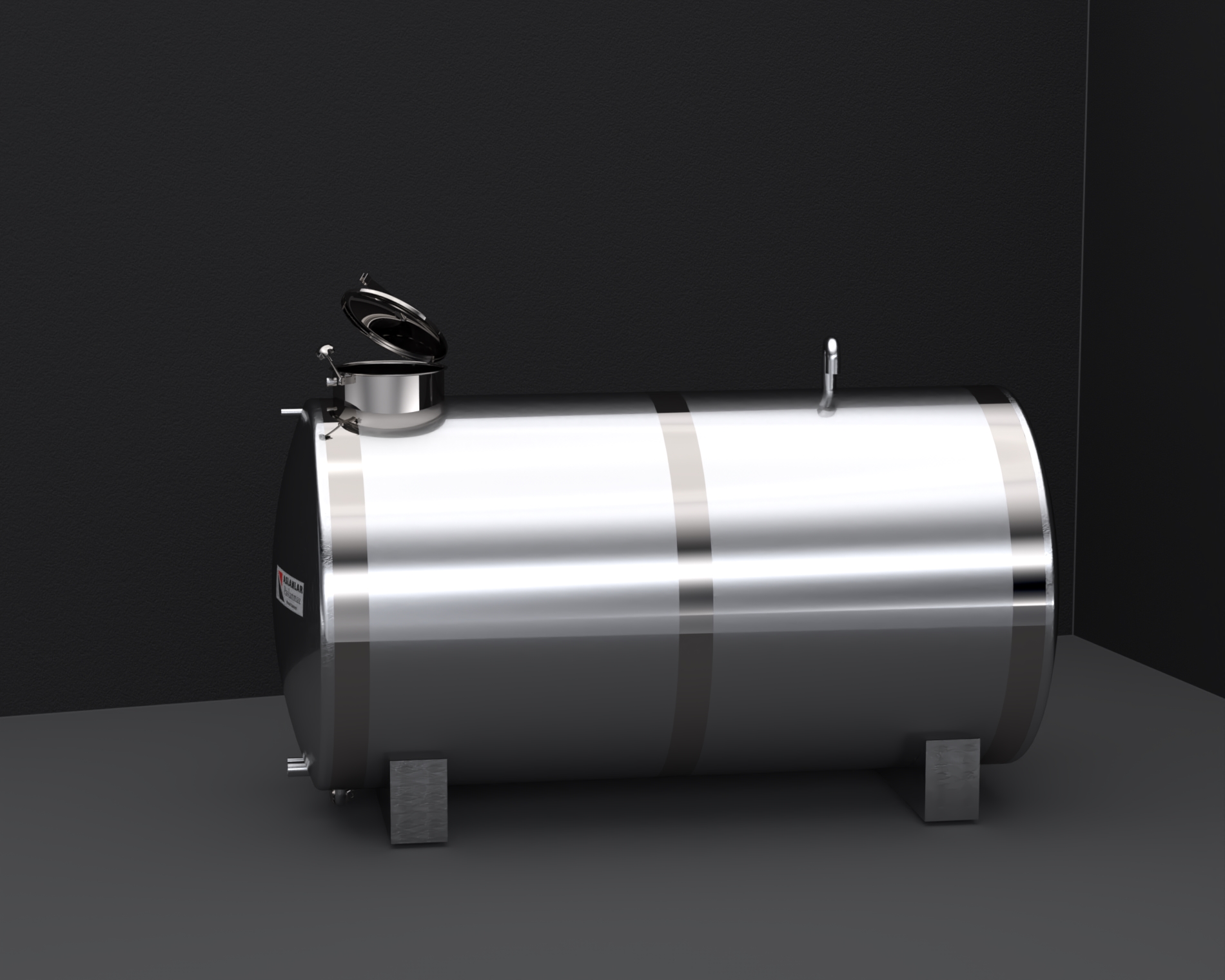

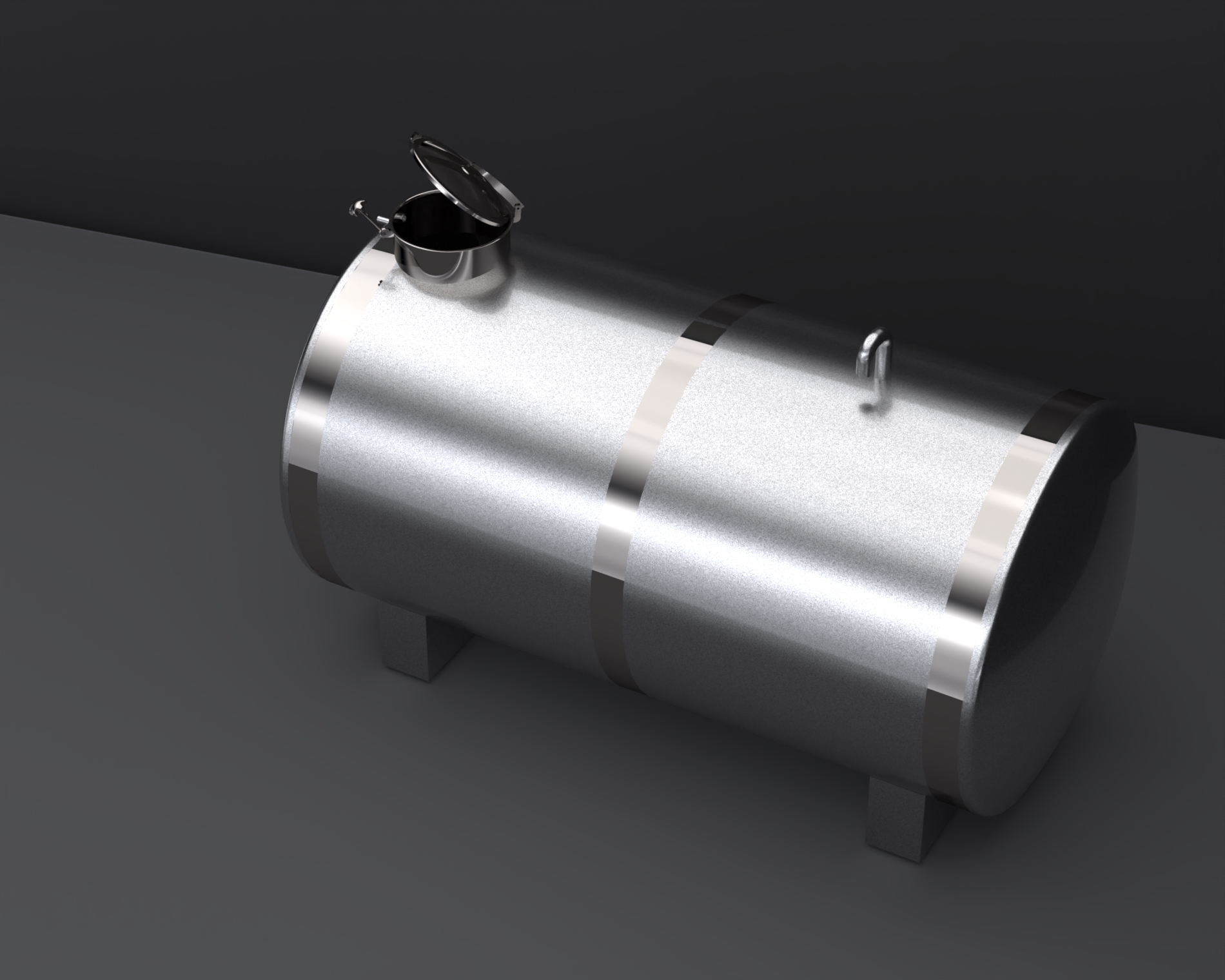

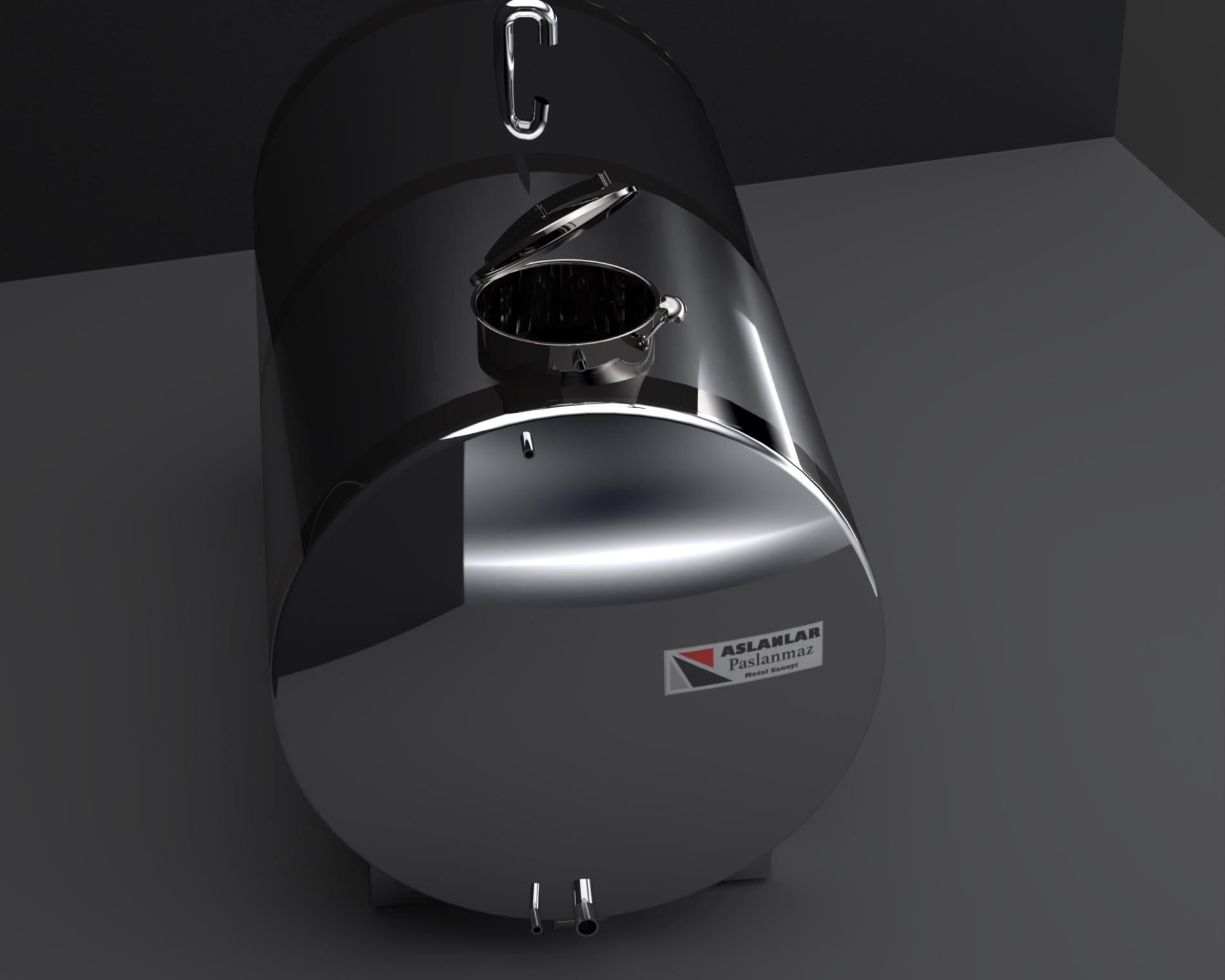

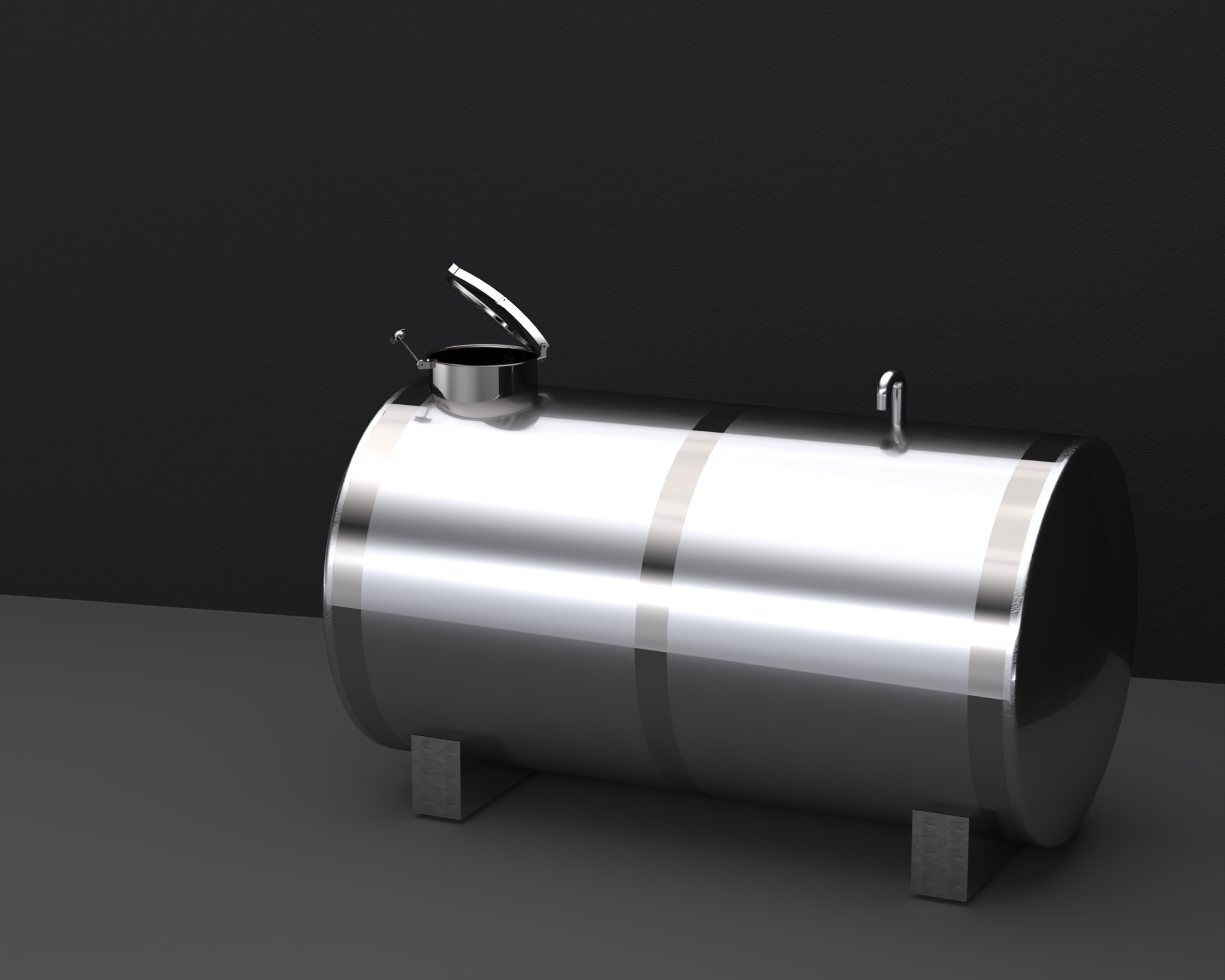

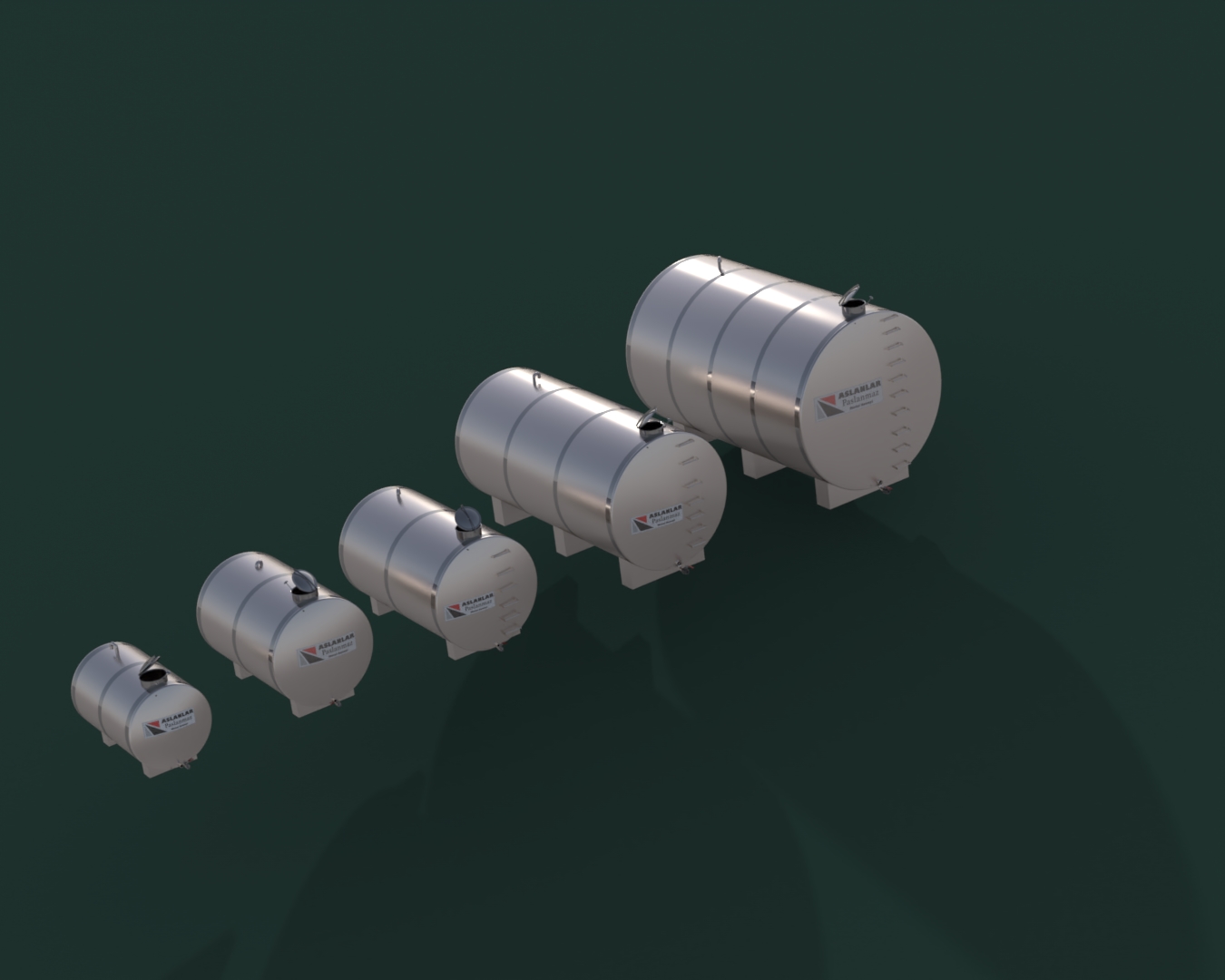

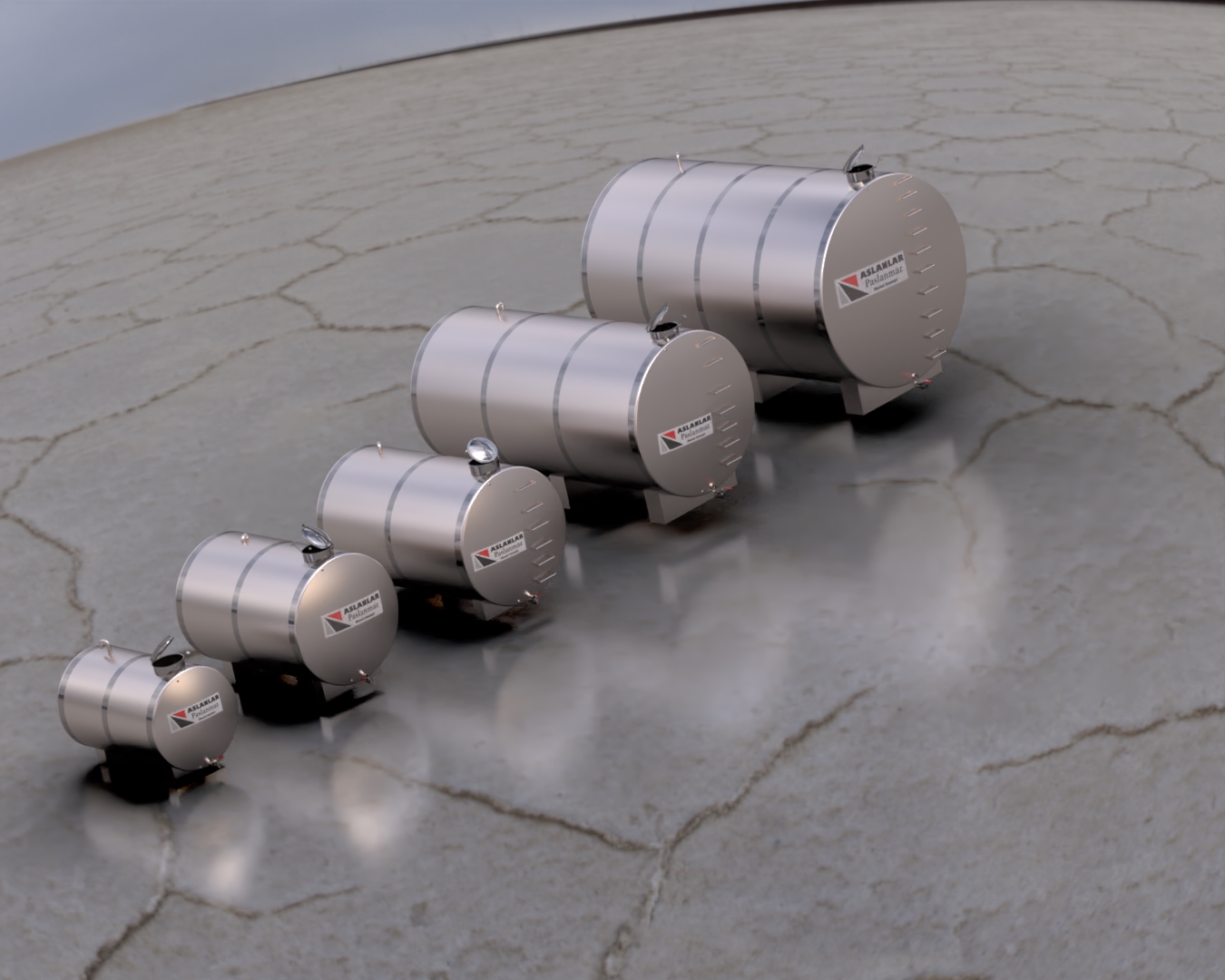

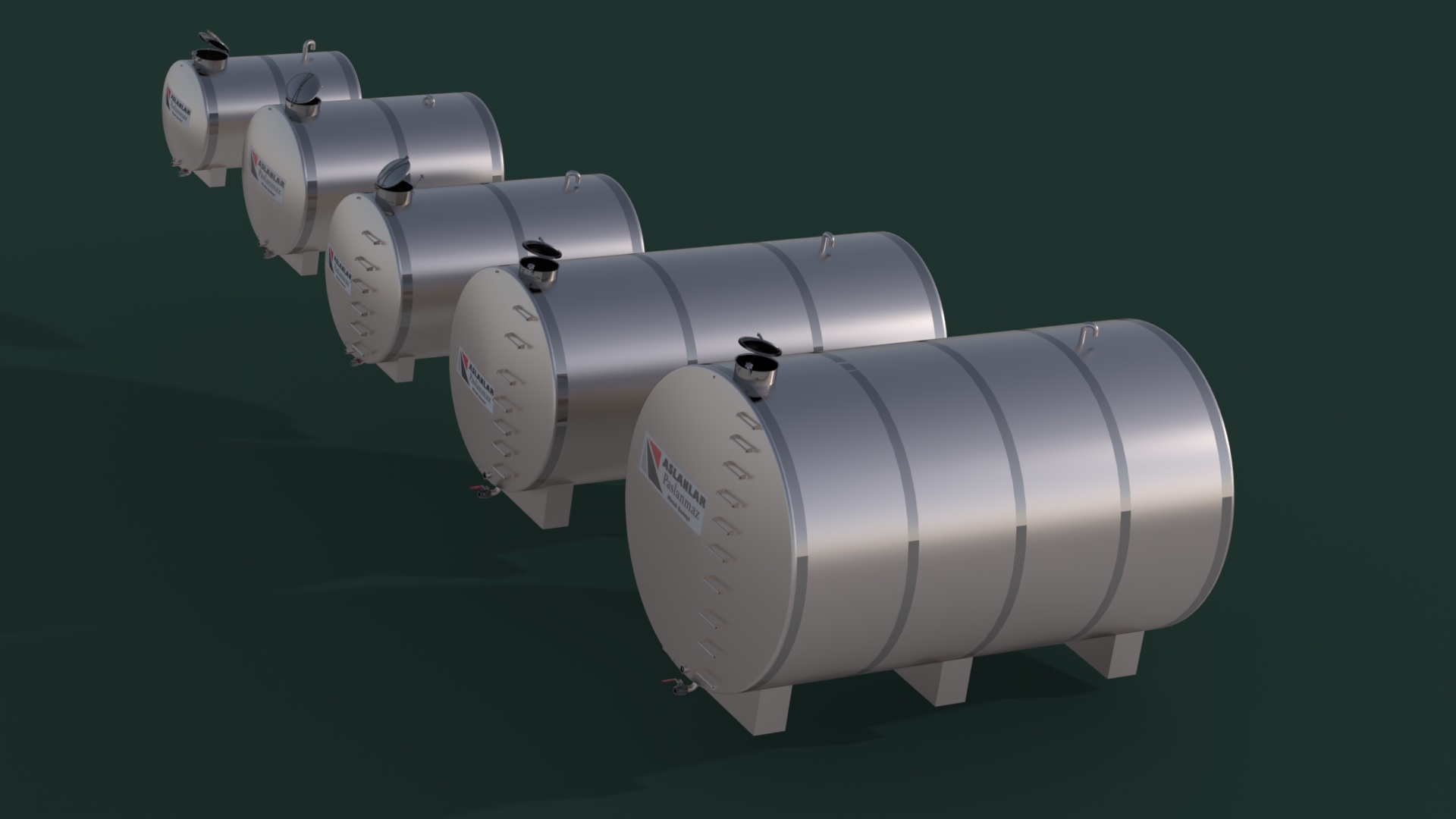

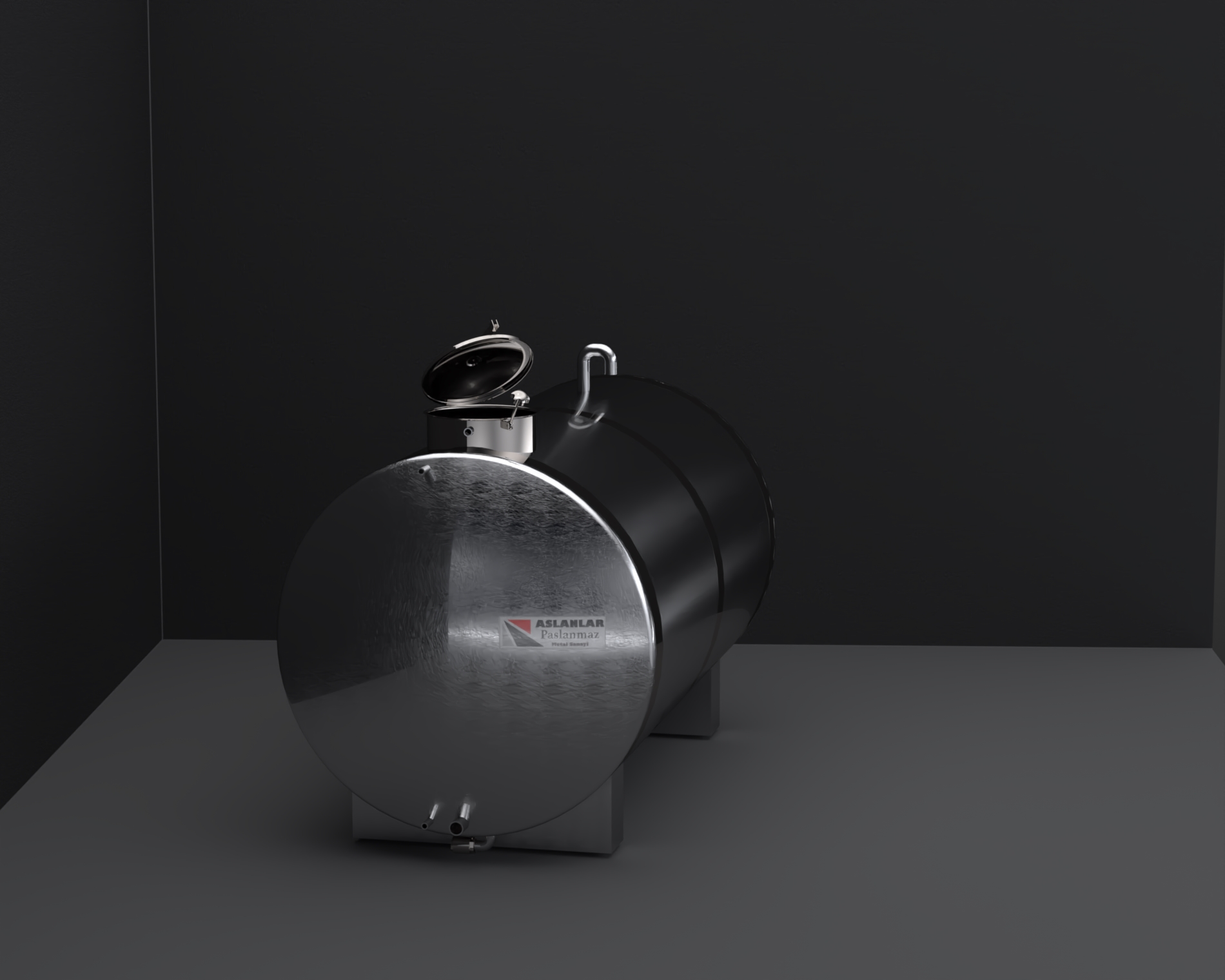

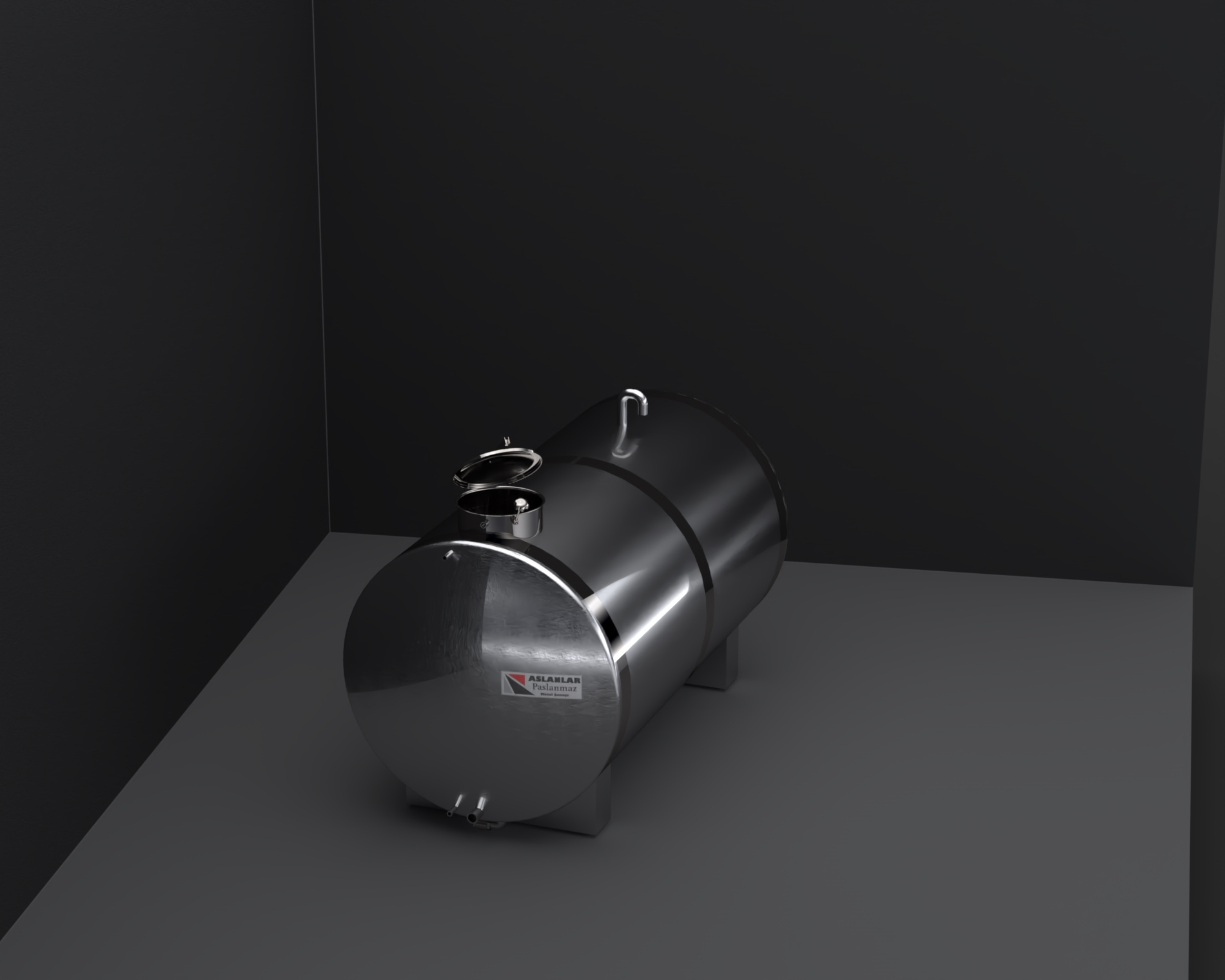

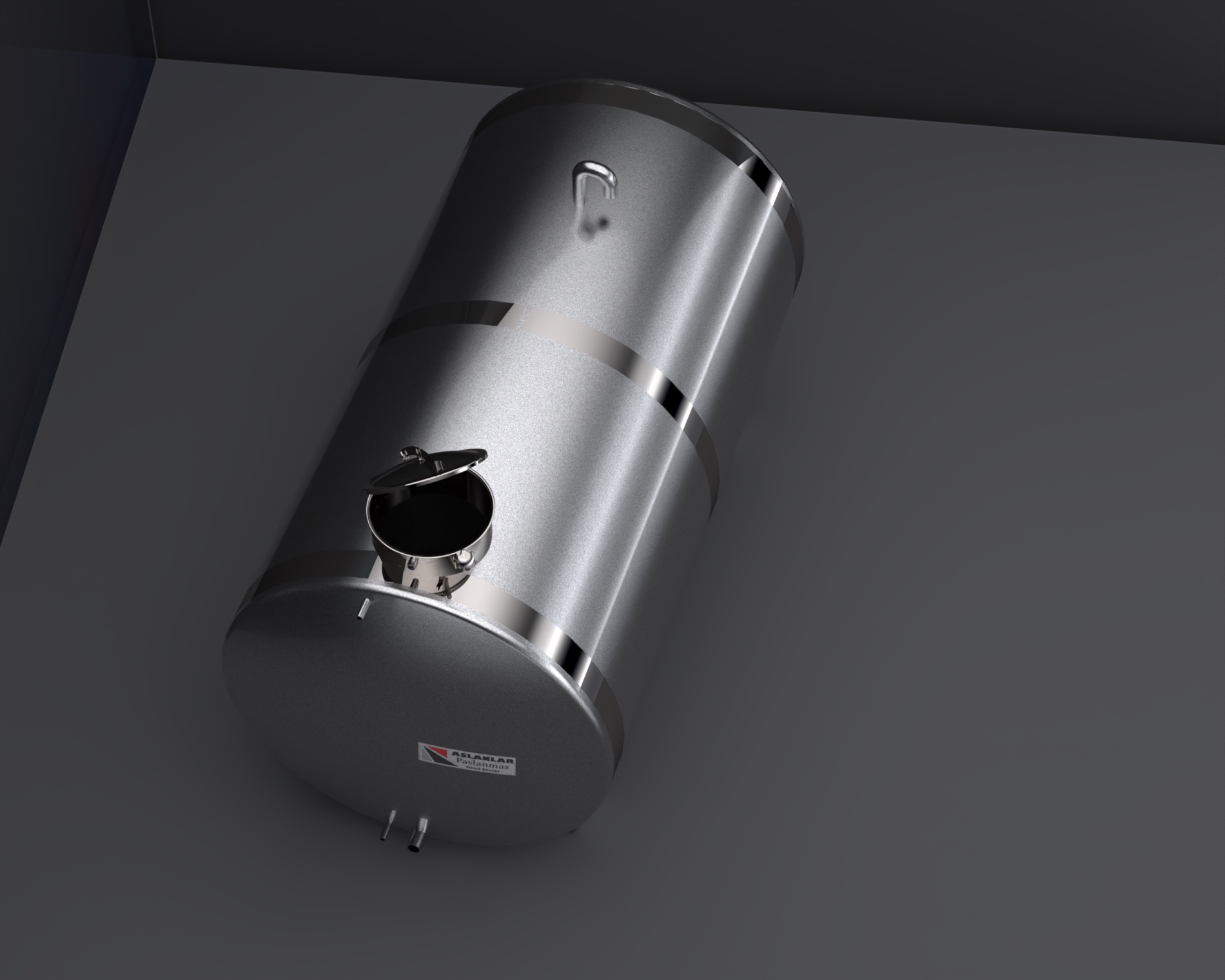

HORIZONTAL TANKS - WATER TANKS

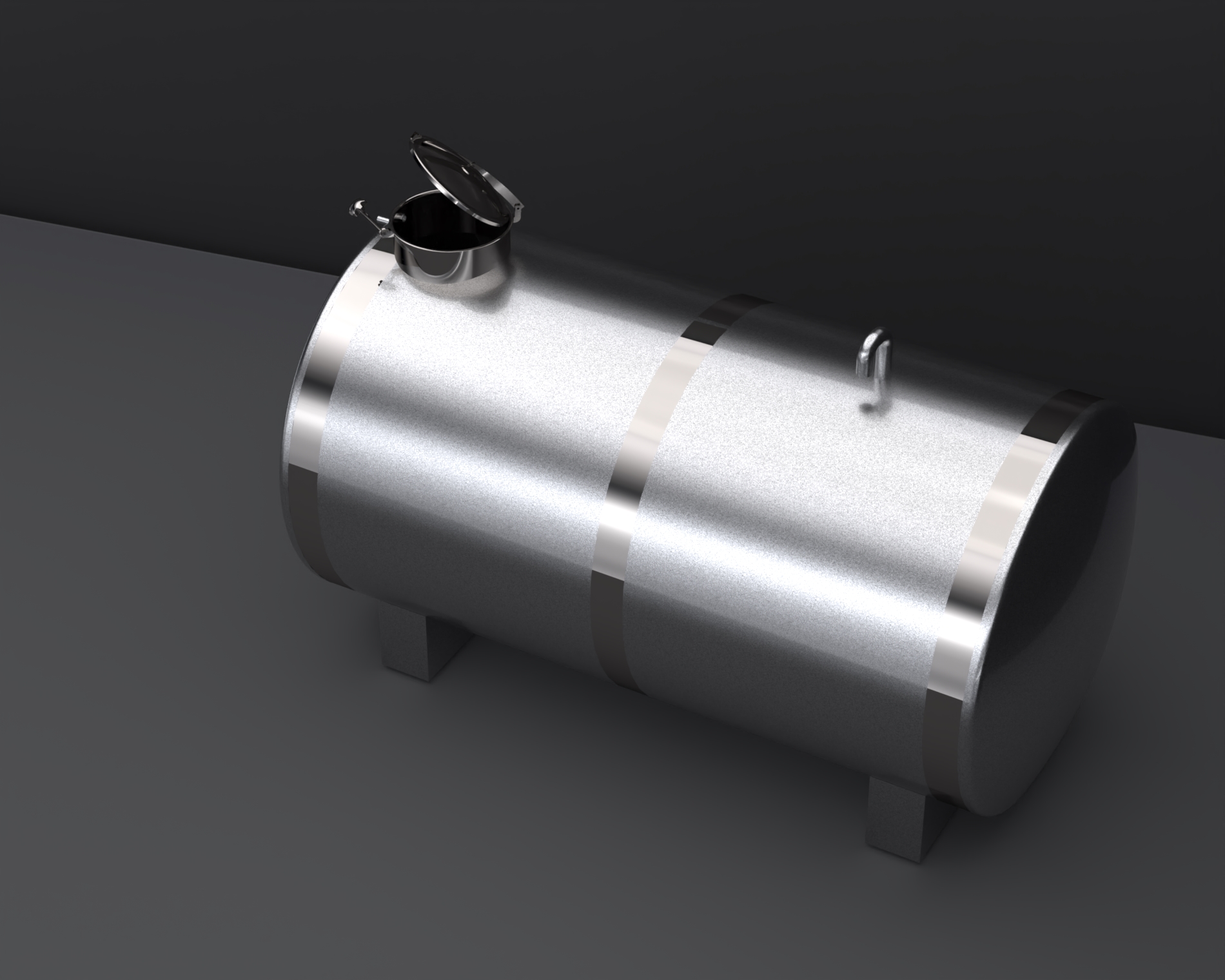

Horizontal water tanks are durable tanks manufactured from stainless steel material in an oval shape parallel to the ground, ensuring the safe storage of water and other liquids. They are preferred in many areas, from industrial facilities to agricultural applications, due to their wide range of uses and long-lasting structures.

Areas of Use

Stainless Steel Storage Tanks and Types

As Asinoks, our stainless steel tank solutions, which we produce for industrial and individual needs, serve a wide range from food safety to chemical resistance. Our stainless steel tank models, manufactured in high quality standards, are as follows:

- Stainless Steel Water Tanks

- Stainless Steel Transport Tanks

- Fermentation Vessels

- Milk Cooling and Stock Tanks

- Fruit Juice Tanks

- Chemical Storage Tanks

- Olive Oil Stock Tanks

- Chocolate and Food Tanks

- Diesel and Fuel Tanks

- Pharmaceutical Preparation Tanks

Stainless steel tanks and tanks are specially produced in the desired tonnages and volumes according to project requirements. You can review the technical dimensions of our most preferred horizontal models below.

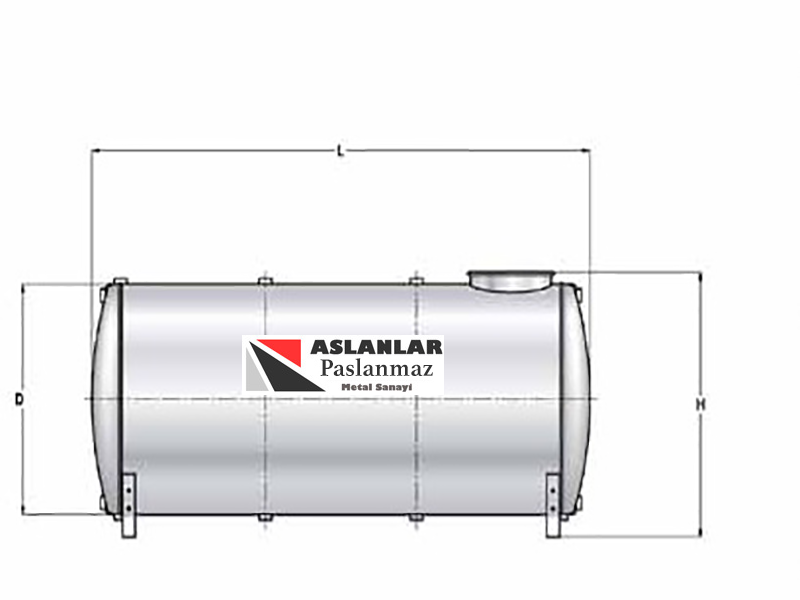

Stainless steel horizontal water tank technical dimension table

Stainless Steel Horizontal Water Tank Dimensions

| Capacity | Diameter (mm) | Length (mm) | Sheet Thickness (mm) |

|---|---|---|---|

| 500 Liters | 750 mm | 1000 mm | 1,5 mm |

| 1 Ton | 920 mm | 1500 mm | 1,5 mm |

| 2 Ton | 1200 mm | 1700 mm | 1,5 mm |

| 3 Ton | 1350 mm | 2000 mm | 1,5 mm |

| 4 Ton | 1420 mm | 2500 mm | 1,5 mm |

| 5 Ton | 1520 mm | 2700 mm | 1,5 mm |

| 6 Ton | 1750 mm | 2500 mm | 2 mm |

| 7 Ton | 1800 mm | 2750 mm | 2 mm |

| 8 Ton | 1920 mm | 2500 mm | 2 mm |

| 9 Ton | 1900 mm | 3000 mm | 2 mm |

| 10 Ton | 1920 mm | 3500 mm | 2 mm |

| 15 Ton | 1920 mm | 4750 mm | 2 mm |

| 20 Ton | 2350 mm | 4700 mm | 3 mm |

| 25 Ton | 2600 mm | 4700 mm | 3 mm |

| 30 Ton | 2850 mm | 4700 mm | 3 mm |

Where are Stainless Steel Tanks Used?

The stainless steel water tanks and industrial tanks we produce play a critical role in the food, chemical and pharmaceutical industries. They are used as transport tanks, fermentation vessels, milk and fruit juice storage units. In addition, chemical tanks for the safe storage of chemical components, olive oil and vegetable oil storage, chocolate production lines and diesel/fuel tanks in the petroleum industry have a wide range of uses.

What Materials are Stainless Steel Tanks Made of?

Storage tanks are manufactured from AISI 304 and 316 quality stainless steel sheets and profiles to ensure maximum durability and hygiene. These materials show superior resistance to corrosion (rusting) and ensure that the liquid inside is preserved for many years without spoiling its structure.

What is a Stainless Steel Water Tank and How Should it be Positioned?

A stainless steel water tank is a container made of metal or food-grade plastic that ensures that water is protected in its healthiest form. It is used in areas such as agricultural irrigation, animal husbandry, chemical production facilities and fire water reserves. It is usually located in the attics of buildings, in basements connected to the hydrophore system, or in open areas.

Water Tank Installation and Assembly

For efficient flow, the water tank should be at least 5 meters above the nearest water outlet point (tap, etc.) that the installation will feed. This elevation difference provides natural pressure. If this height cannot be achieved, the pressure should be increased with hydrophore support.

Why Should Stainless Steel Tanks Be Preferred?

Although there are alternatives such as polyethylene, polyester or galvanization on the market; stainless steel tanks are the most reliable option in terms of human health, hygiene and leak-proofness. It does not produce bacteria, does not hold algae and is easy to clean.

The Importance of Horizontal Stainless Steel Tanks in Food Products

Horizontal water tanks, which are produced in cylindrical or prismatic form, fully comply with food safety standards. It is indispensable especially in the following areas:

- Liquid Food Products: Thanks to its corrosion-resistant surface, foods do not get a metallic taste and stay fresh for a long time.

- Beverage Industry: The risk of spoilage is minimized with hygienic storage in beverages such as fruit juice, wine or turnip juice.

- Milk and Dairy Products: Milk tanks have a smooth stainless steel surface that prevents bacteria formation during cooling and storage stages.

This diversity proves how functional horizontal stainless steel tanks are. The main purpose is to protect the stored product from external factors and store it in the most hygienic conditions.

Stainless Steel Water Tanks: Transport tanks, fermentation vessels, milk tanks,

fruit juice tanks,

chemical tanks for chemical liquids, olive oil storage and oil tanks, chocolate tanks, oil and diesel tanks in the petroleum products sector, pharmaceutical tanks in the pharmaceutical sector are used.

Stainless tanks are produced from stainless steel sheets, profiles, and stainless steel products. They are durable and long-lasting.

A water tank is a container made of metal or plastic material for water storage and plumbing. Water tanks are used for water storage in many fields such as both plants and livestock, chemical production, food preparation, irrigation, agriculture, firefighting, and agricultural agriculture.

The water tank must be at least 5 meters above the nearest water outlet. If the water outlet is close to the tank, the water pressure will be insufficient.

Water tanks are manufactured from stainless steel sheets and stainless metals. In our sector, water tank production is carried out with many materials such as polyethylene, polyester, and galvanized steel. Stainless steel tanks are preferred more.

Cylindrical stainless steel tanks can be preferred in areas where various food products are stored, due to their ability to ensure hygienic conditions. For example:

Liquid Food Products: Food products, especially those at risk of corrosion, can be used in prismatic stainless steel tanks. Food products stored in such tanks can stay fresh for a longer time due to their ability to ensure hygienic conditions.

Beverages: When beverages are stored in prismatic stainless steel tanks in a way that ensures hygienic conditions, the risk of spoilage is reduced, and they can stay fresh for a longer time.

Milk and dairy products: Milk and dairy products can stay fresh for a longer time due to the hygienic conditions provided by prismatic stainless steel tanks. Milk and dairy products stored in such tanks have a reduced risk of spoilage, and hygienic conditions are ensured.

These examples are just a few, and prismatic stainless steel tanks can be preferred in areas where various other food products are also stored. The important thing is that the materials being stored are kept in tanks made of stainless steel materials, to ensure hygienic conditions and to prevent corrosion.