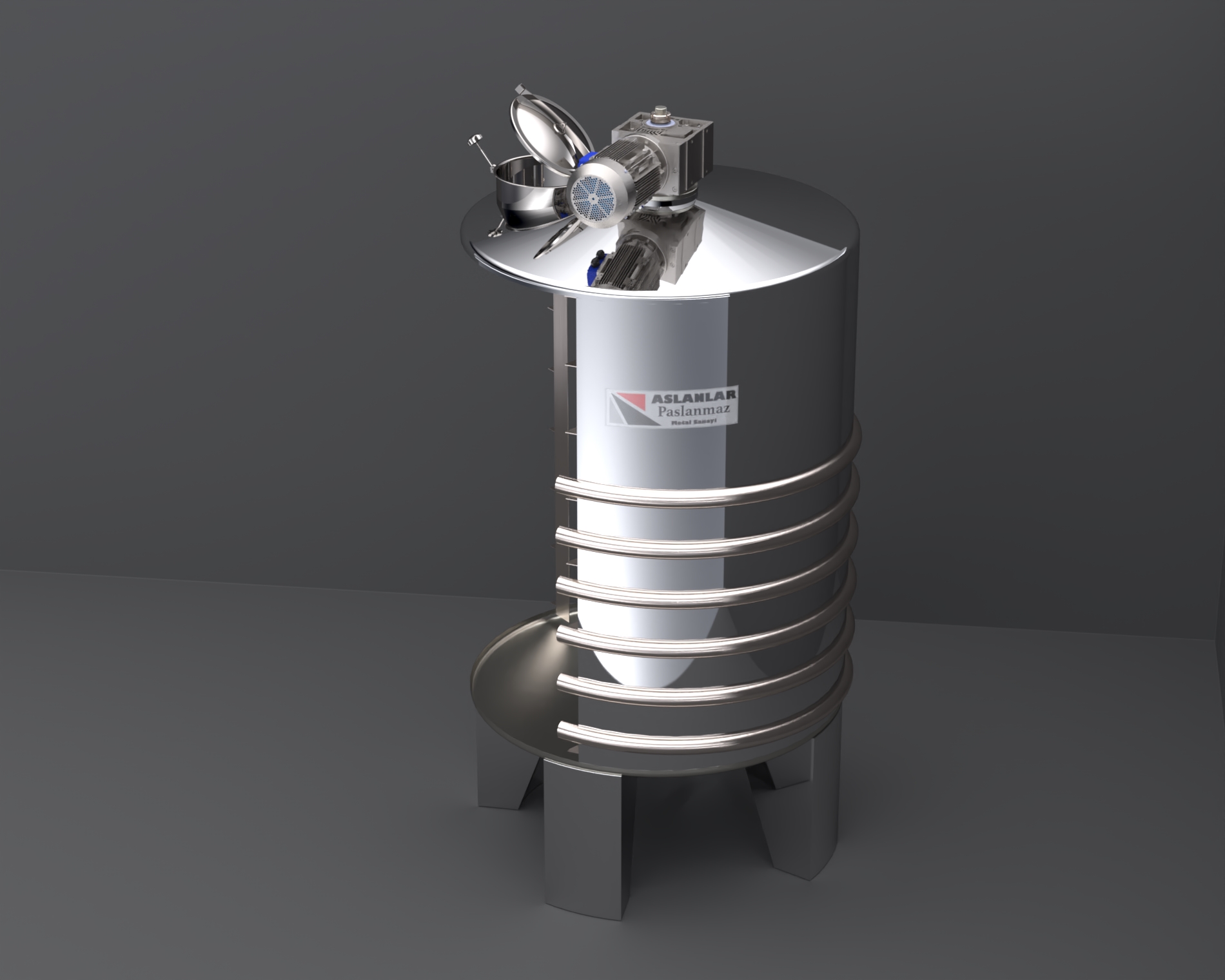

What is a Stainless Steel Reactor?

A stainless steel reactor is a vessel used to carry out chemical reactions under controlled conditions—such as pressure, temperature, and agitation. Made primarily from stainless steel for its strength and corrosion resistance, these reactors are a staple in many industries.

Why Are Stainless Steel Reactors Important?

These reactors are crucial for creating consistent, repeatable, and scalable chemical processes. They’re built to withstand harsh chemicals, extreme temperatures, and high pressures—making them ideal for everything from pharmaceuticals to petrochemicals.

Types of Stainless Steel Reactors

Batch Reactors

Perfect for small-scale or specialty processes. Everything goes in at once, reacts, and then comes out. Simple and flexible.

Continuous Reactors

Here, reactants flow in, reactions happen, and products flow out—constantly. Ideal for large-scale production.

Semi-Batch Reactors

A hybrid of the two, allowing for better control over certain reactions by adding components in stages.

Catalytic Reactors

These come equipped with catalysts to speed up reactions. Often used in energy and fuel applications.

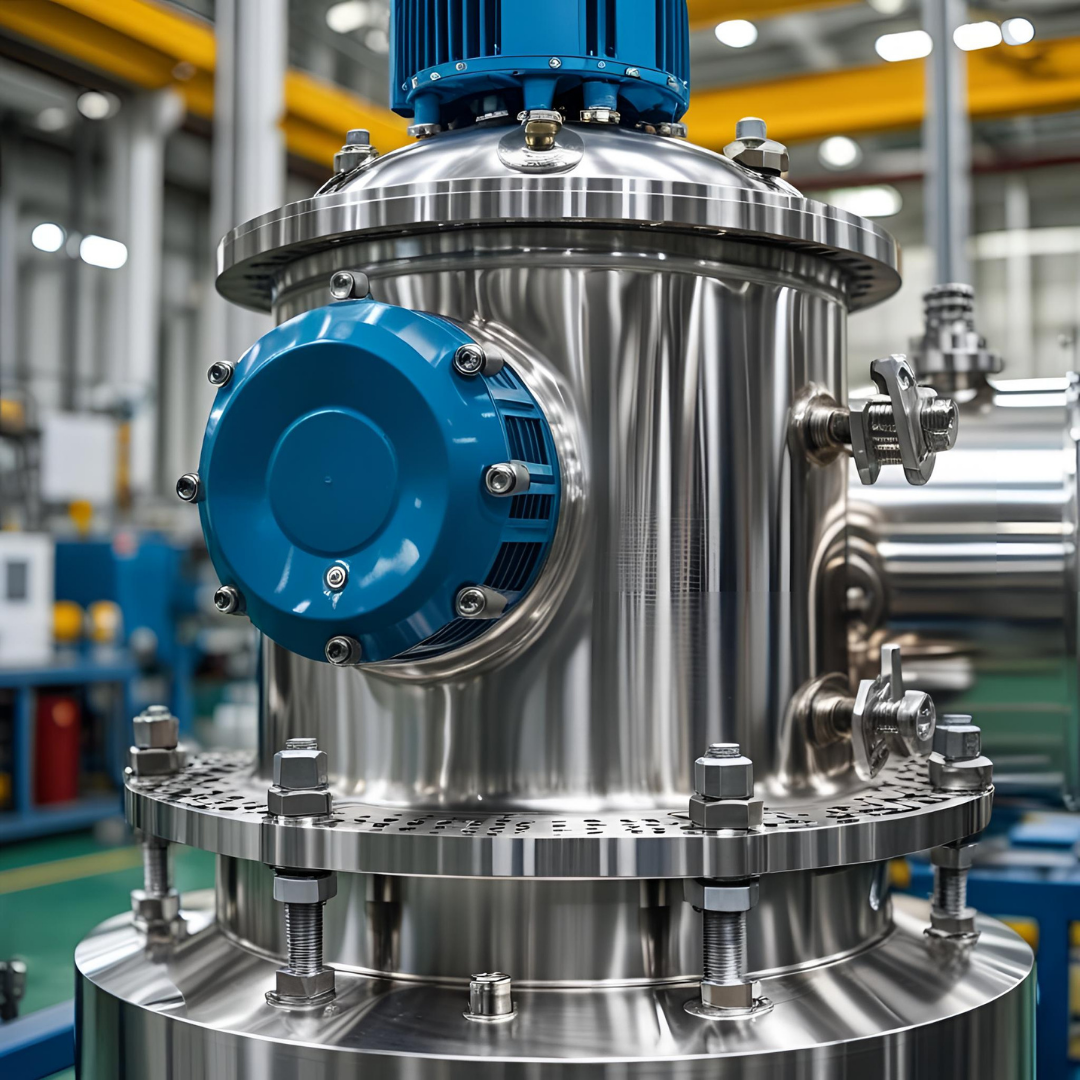

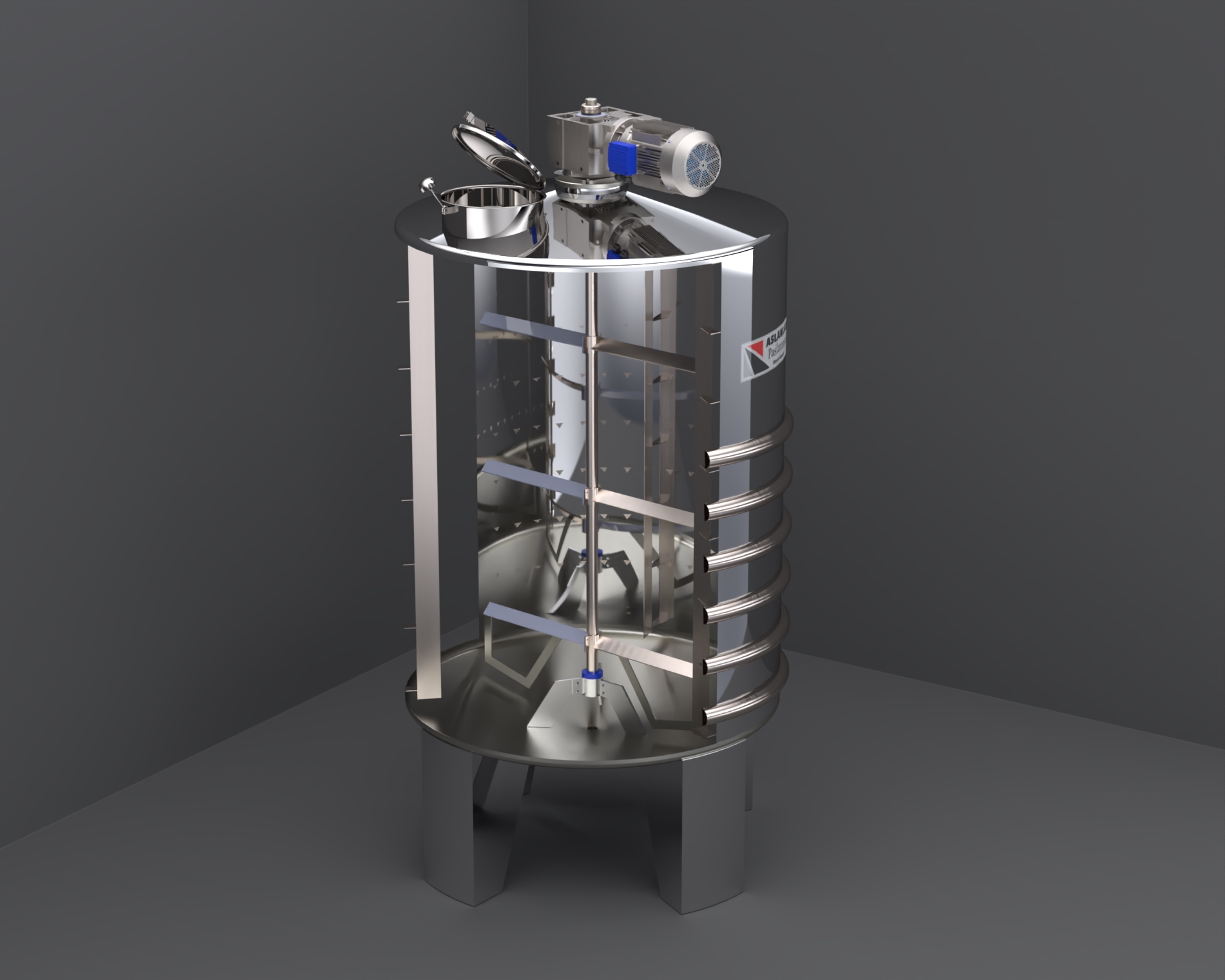

Components of a Stainless Steel Reactor

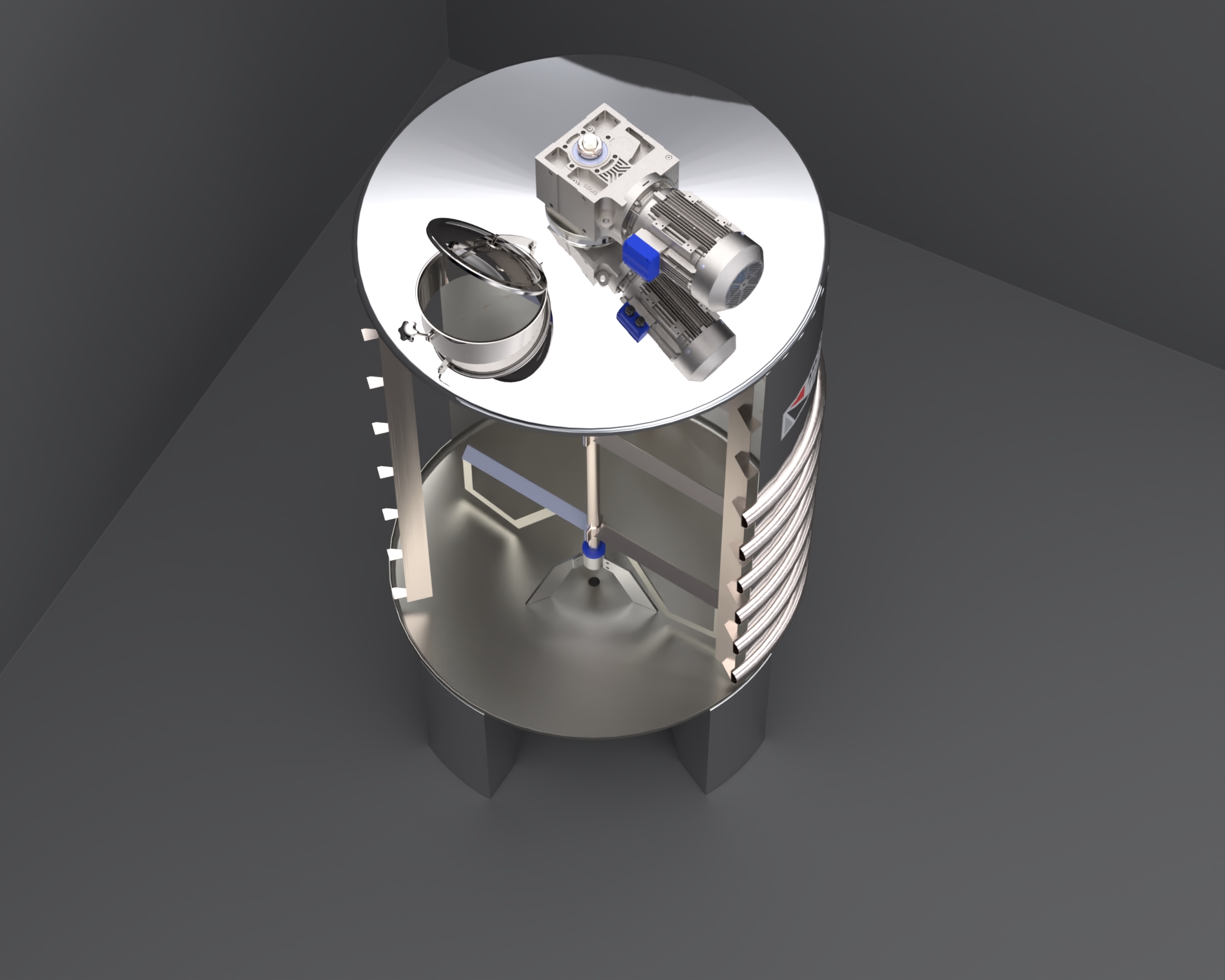

Reactor Vessel

This is the core. It holds the materials and provides the controlled environment for reactions.

Agitator System

Think of this as the mixer. It keeps materials well blended for uniform reactions.

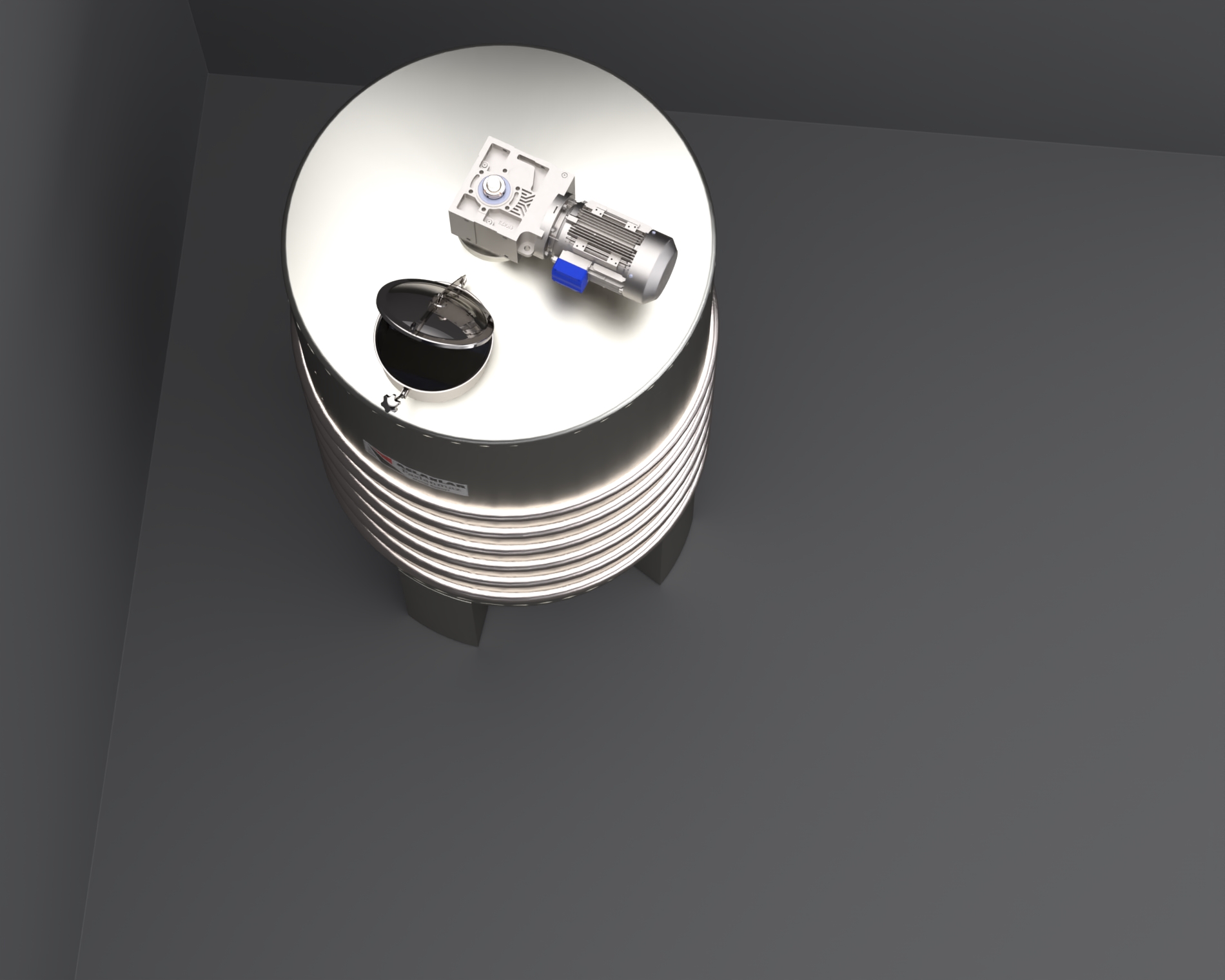

Heating & Cooling Jackets

These maintain the temperature, making sure reactions proceed safely and efficiently.

Control Systems

Modern reactors come with digital panels and sensors for precise monitoring and automation.

Material Grades Used in Stainless Steel Reactor

SS304 and Its Applications

Great for basic food-grade and low-corrosion applications. Affordable and reliable.

SS316: Resistance and Reliability

With added molybdenum, SS316 is more corrosion-resistant—especially in saline or acidic environments.

Duplex Stainless Steel for Harsh Conditions

Combines strength and corrosion resistance. Often used in extreme chemical processes.

Advantages of Stainless Steel Reactors

Corrosion Resistance

Stainless steel doesn’t rust easily, which is a game-changer for chemical processing.

High Durability

These reactors are built to last—even under tough conditions.

Easy Maintenance and Cleaning

Smooth internal surfaces mean less residue and easier cleaning.

Pressure and Temperature Tolerance

Stainless steel can handle high stress without cracking or warping.

Applications Across Industries

Pharmaceutical Industry

Used for producing drugs under strict hygiene and quality standards.

Chemical Processing Plants

Ideal for mixing, heating, and reacting aggressive chemicals.

Food & Beverage Sector

From sauces to spirits, reactors play a vital role in processing.

Cosmetics and Skincare Industry

Perfect for emulsions, gels, and lotions.

Petrochemical and Oil Refining

Used in the production of fuels, lubricants, and additives.

How to Choose the Right Stainless Steel Reactor

Capacity and Size

Bigger isn’t always better. Choose based on your batch size and production volume.

Type of Reaction

Exothermic, endothermic, or catalytic? The reactor type matters.

Operating Conditions

Consider pressure, temperature, and agitation needs.

Material Compatibility

Ensure the reactor material won’t react with your product.

Maintenance and Cleaning Tips

CIP (Clean-In-Place) Techniques

Automated systems that clean without disassembly.

Regular Inspection

Check for cracks, corrosion, or leaks.

Preventing Contamination

Always clean between batches to avoid cross-contamination.

Ensuring Longevity

Follow manufacturer guidelines to keep the reactor running for years.

Safety Standards and Certifications

ASME Standards

Ensures mechanical integrity under pressure.

GMP Compliance

Critical for pharmaceutical and food industries.

ISO Certifications

Guarantees quality management and process consistency.

Innovations in Stainless Steel Reactors

Automation & Smart Controls

Digital systems for real-time monitoring and control.

Energy-Efficient Jacket Designs

New jacket types save energy and boost efficiency.

Modular Reactor Systems

Easier to scale, modify, and upgrade.

Stainless Steel Reactor vs. Glass-Lined Reactor

Performance Comparison

Stainless steel is stronger and handles pressure better.

Cost Efficiency

While pricier upfront, stainless steel saves more over time.

Safety and Durability

Glass-lined can crack; stainless steel? Not so much.

Customization Options

Jacket Types (Limpet, Dimple, etc.)

Choose based on heating/cooling efficiency needs.

Agitation Speed and Blade Type

Match your product’s viscosity and reaction needs.

Ports and Nozzles

More ports mean more flexibility in operations.

Instrumentation and Control Panels

Tailored controls make your system smarter and safer.

Environmental Impact and Sustainability

Recyclability of Stainless Steel

It’s 100% recyclable—great for green manufacturing.

Energy Efficiency

Modern reactors are designed to conserve energy.

Waste Reduction

Closed systems mean less spillage and waste.

Cost Factors

Initial Investment vs. Long-Term Savings

Yes, it’s expensive upfront—but the long-term ROI is unbeatable.

Installation and Setup Costs

Includes base, fittings, piping, and controls.

Maintenance Costs

Minimal, especially with proper care.

Conclusion

A stainless steel reactor isn’t just another piece of equipment—it’s the backbone of efficient, safe, and high-quality chemical processing. From pharmaceuticals to food, its advantages in durability, cleanliness, and versatility are unmatched. Whether you’re a startup or an industrial giant, investing in the right reactor can make or break your production line.

FAQs

1. What is the lifespan of a stainless steel reactor?

With proper maintenance, stainless steel reactors can last 15–30 years or more.

2. Can stainless steel reactors handle corrosive materials?

Absolutely—especially grades like SS316 and duplex stainless steel.

3. How do I know which reactor type is right for my business?

It depends on your reaction type, volume, and processing conditions. Consulting with a manufacturer is always a good idea.

4. Are stainless steel reactors suitable for small-scale production?

Yes, they come in various sizes and are perfect for pilot plants and R&D labs.

5. How often should a stainless steel reactor be serviced?

At least once a year for inspections, with regular cleaning between uses.