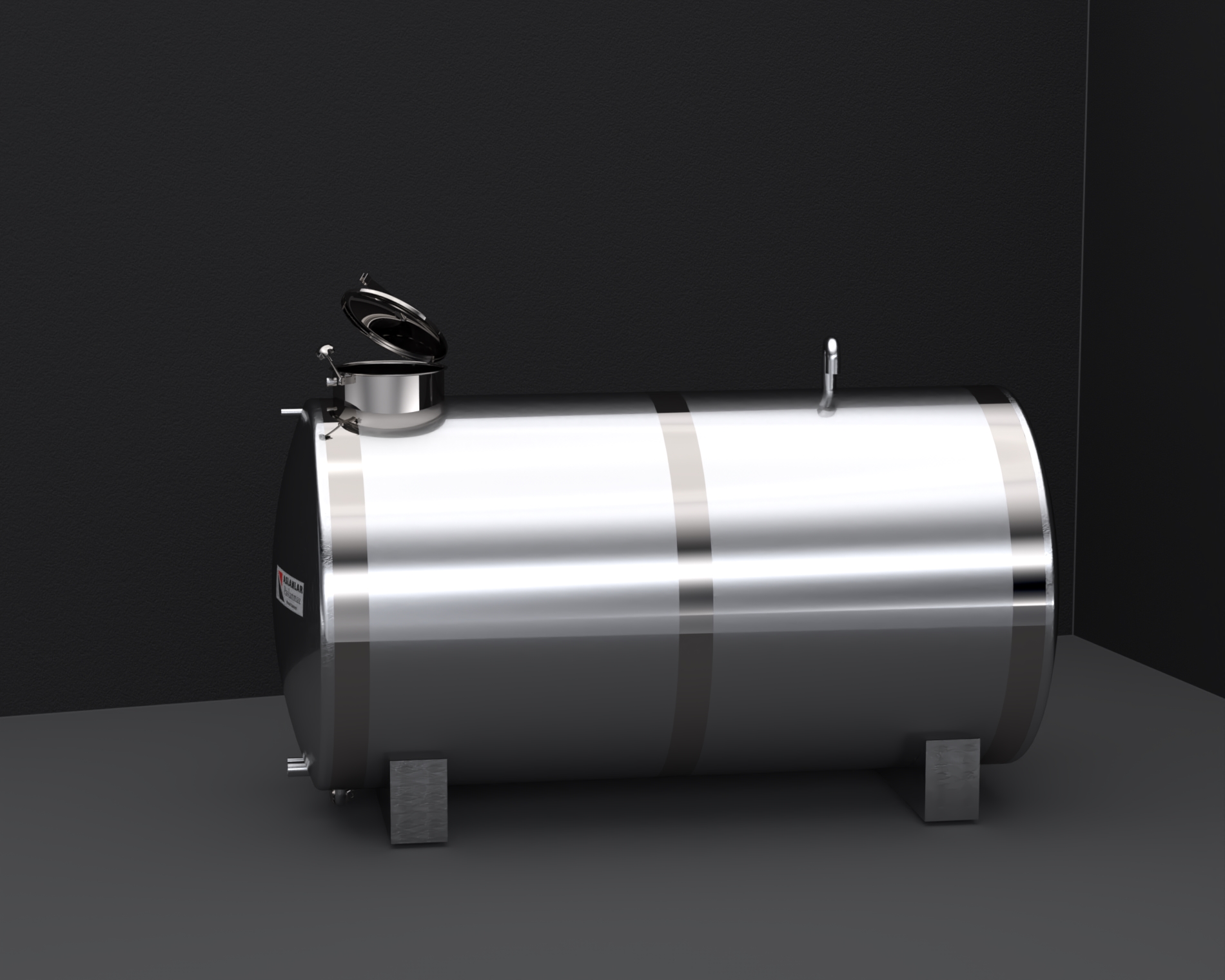

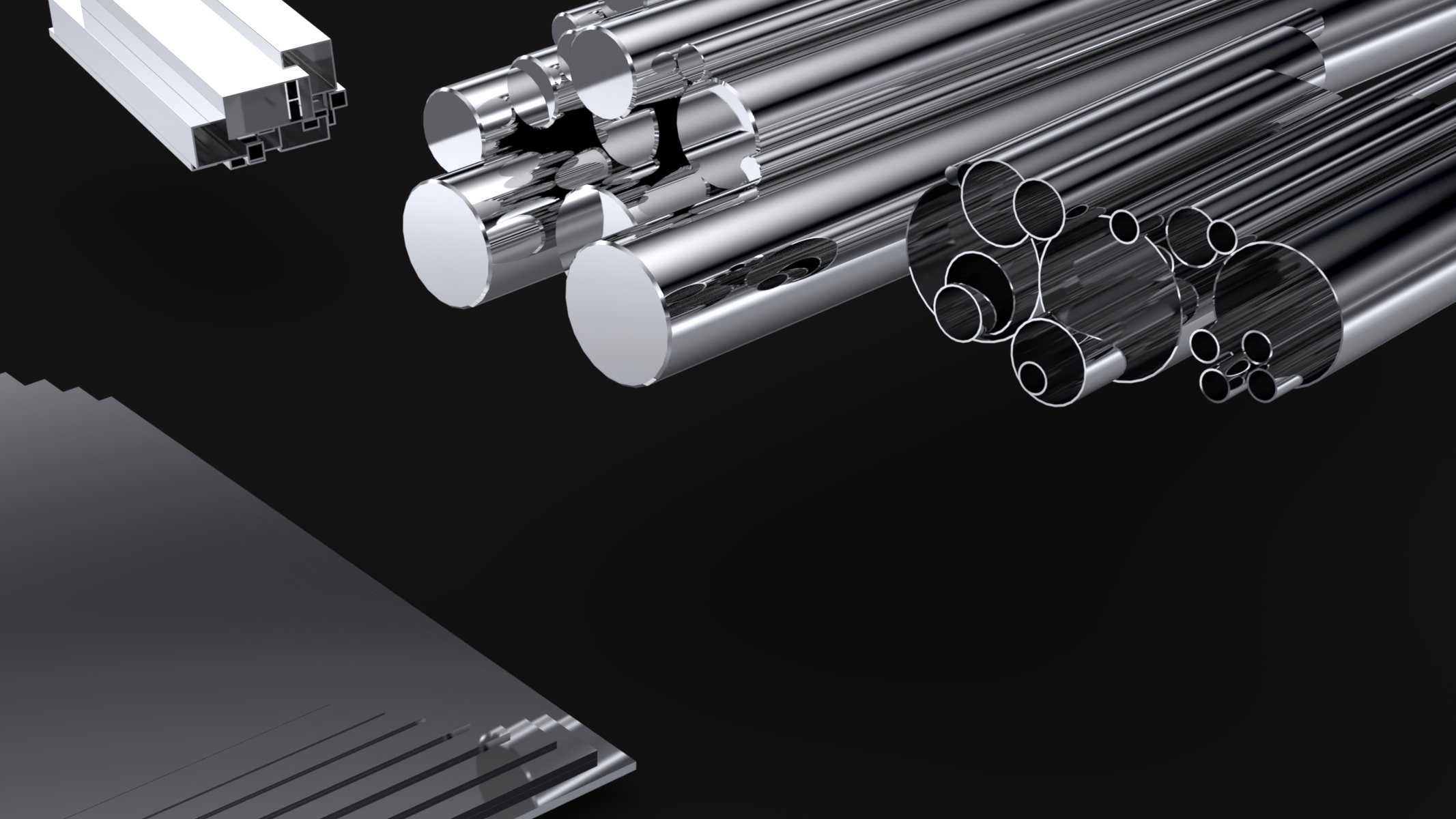

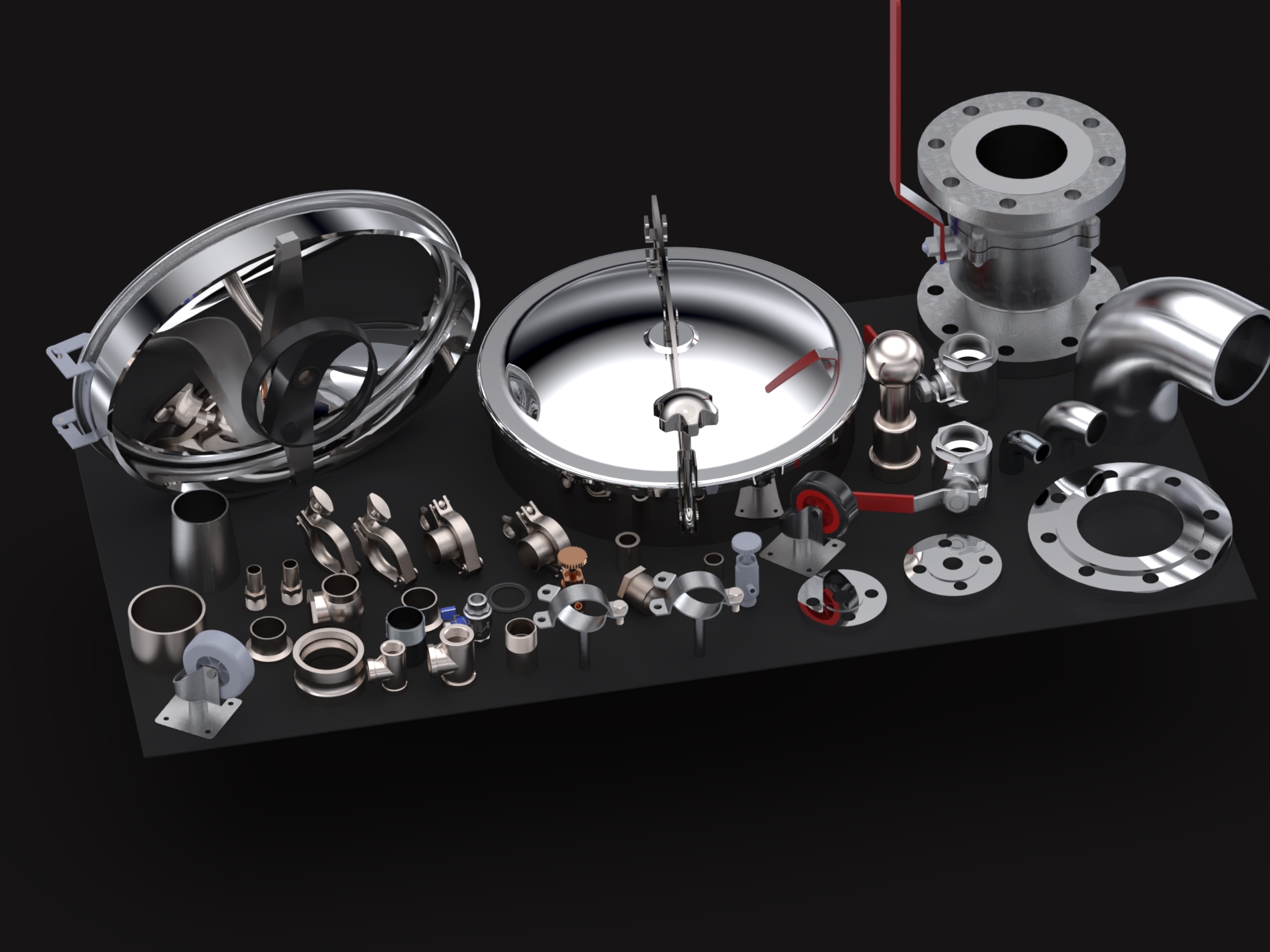

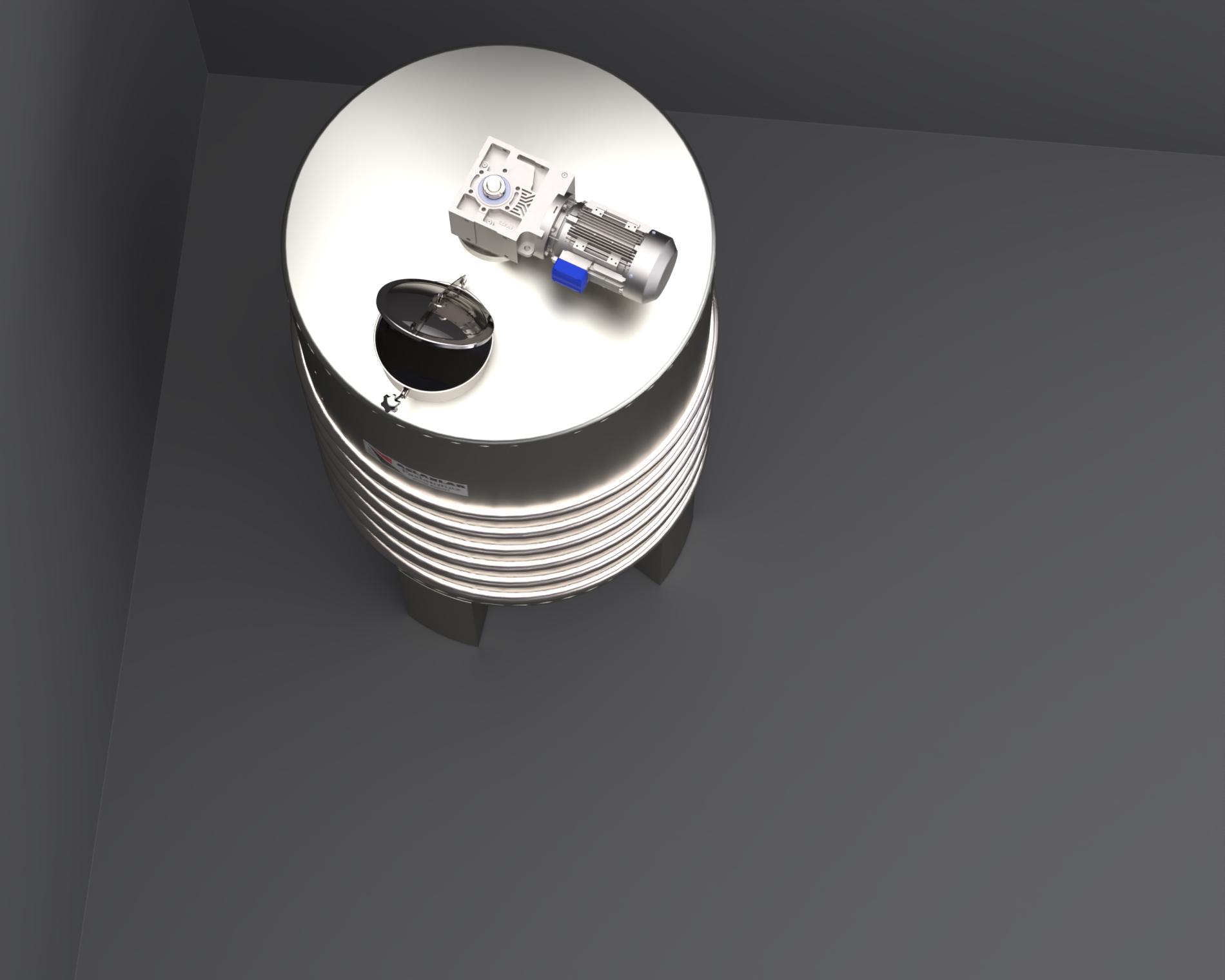

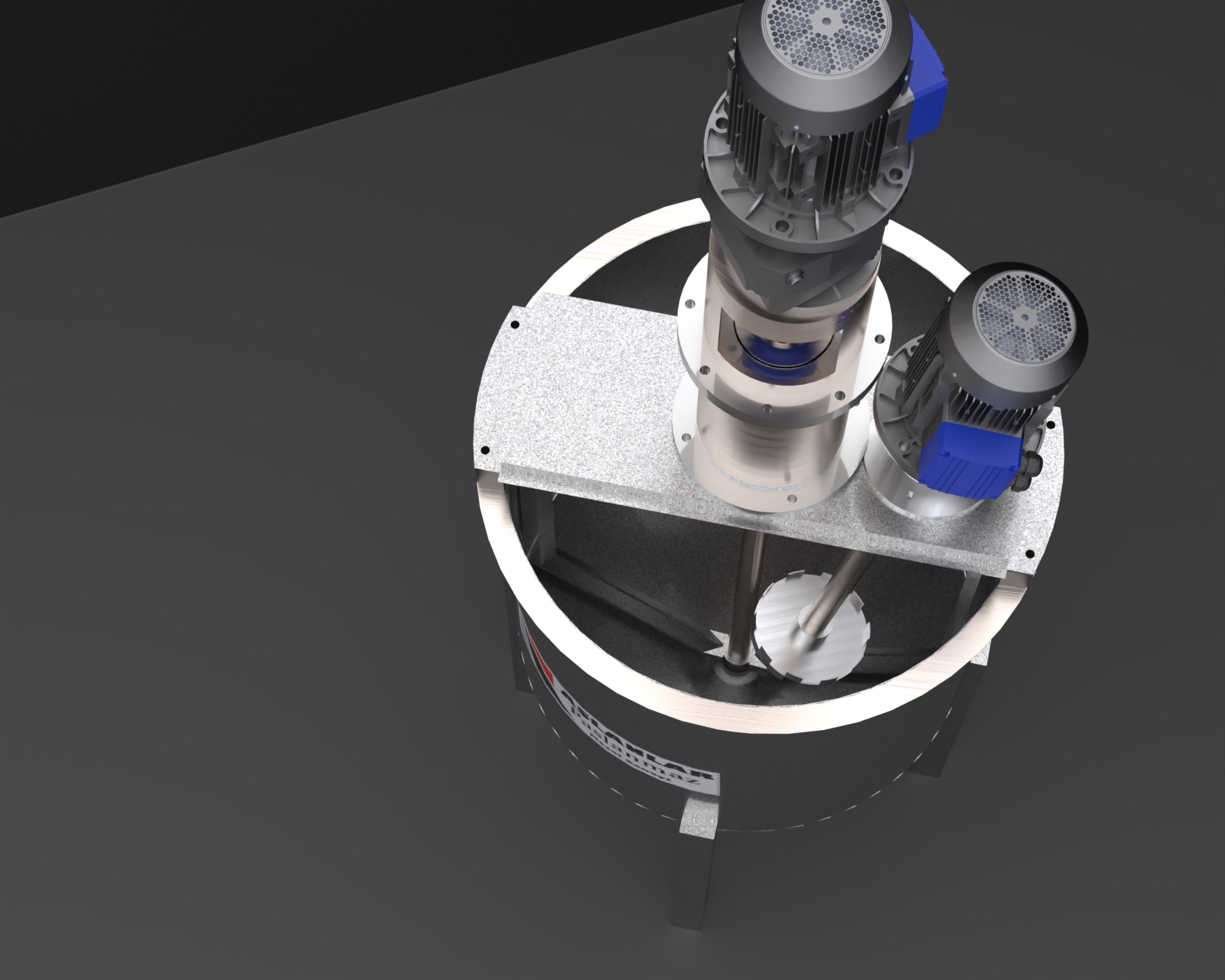

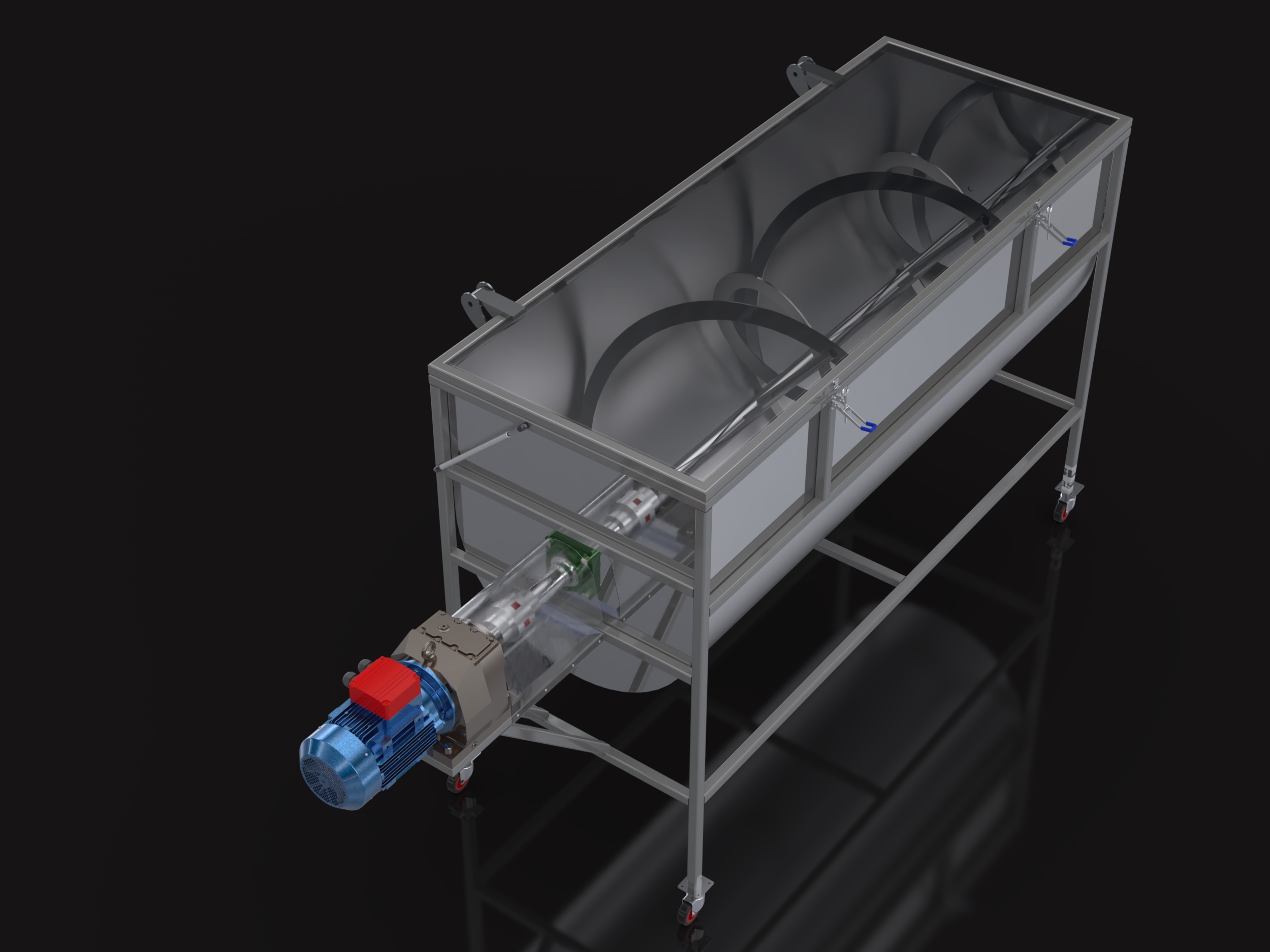

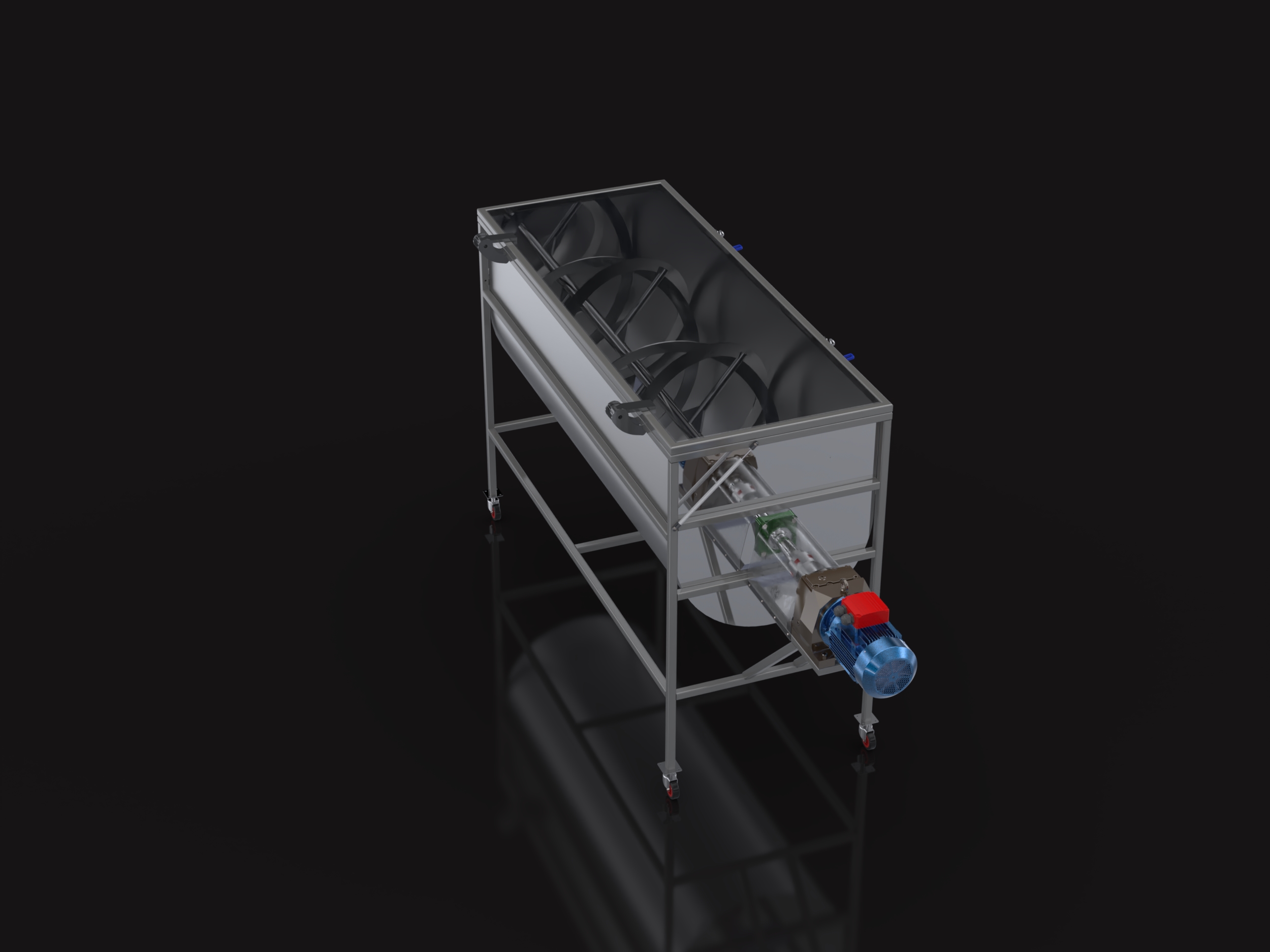

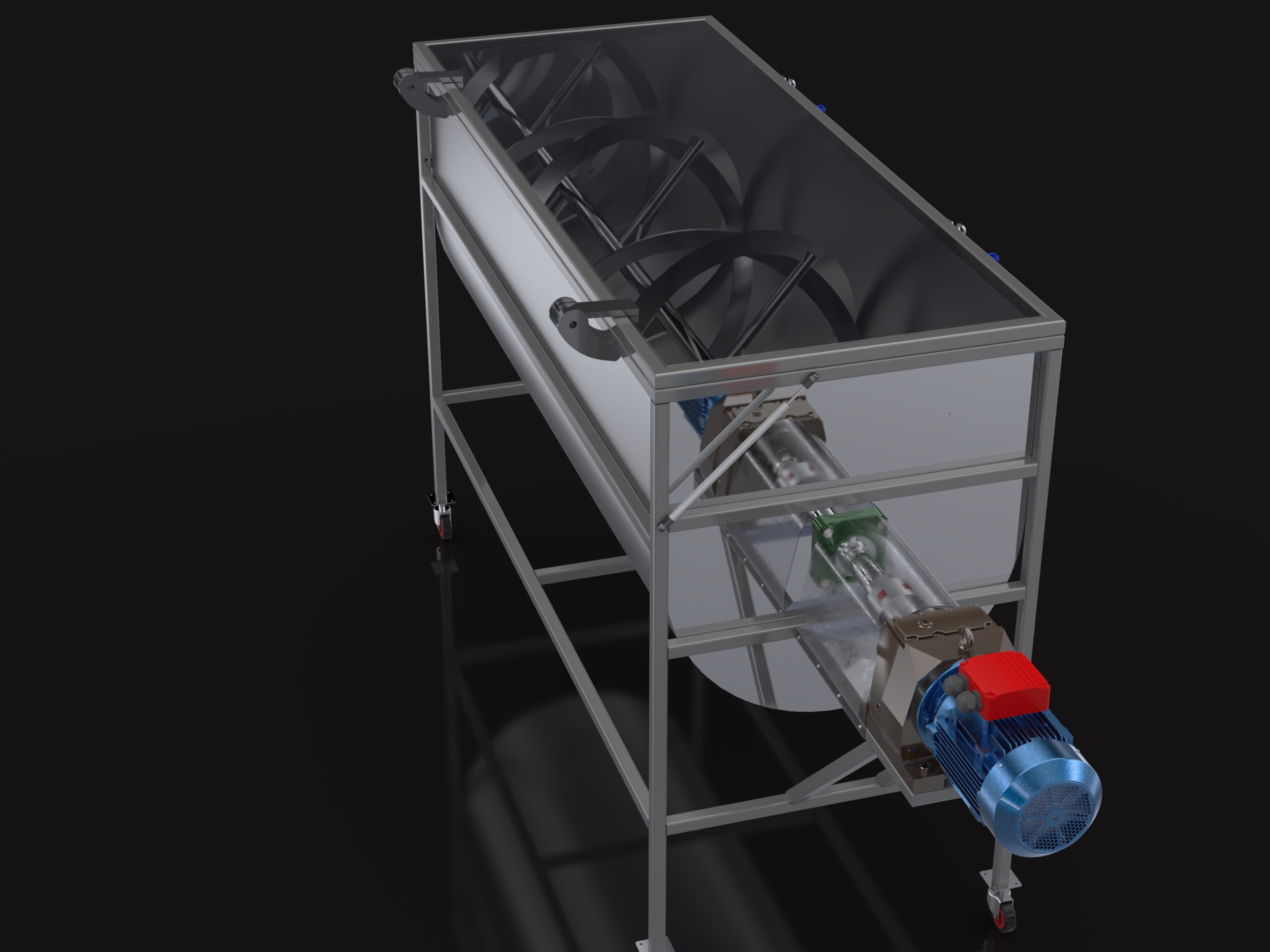

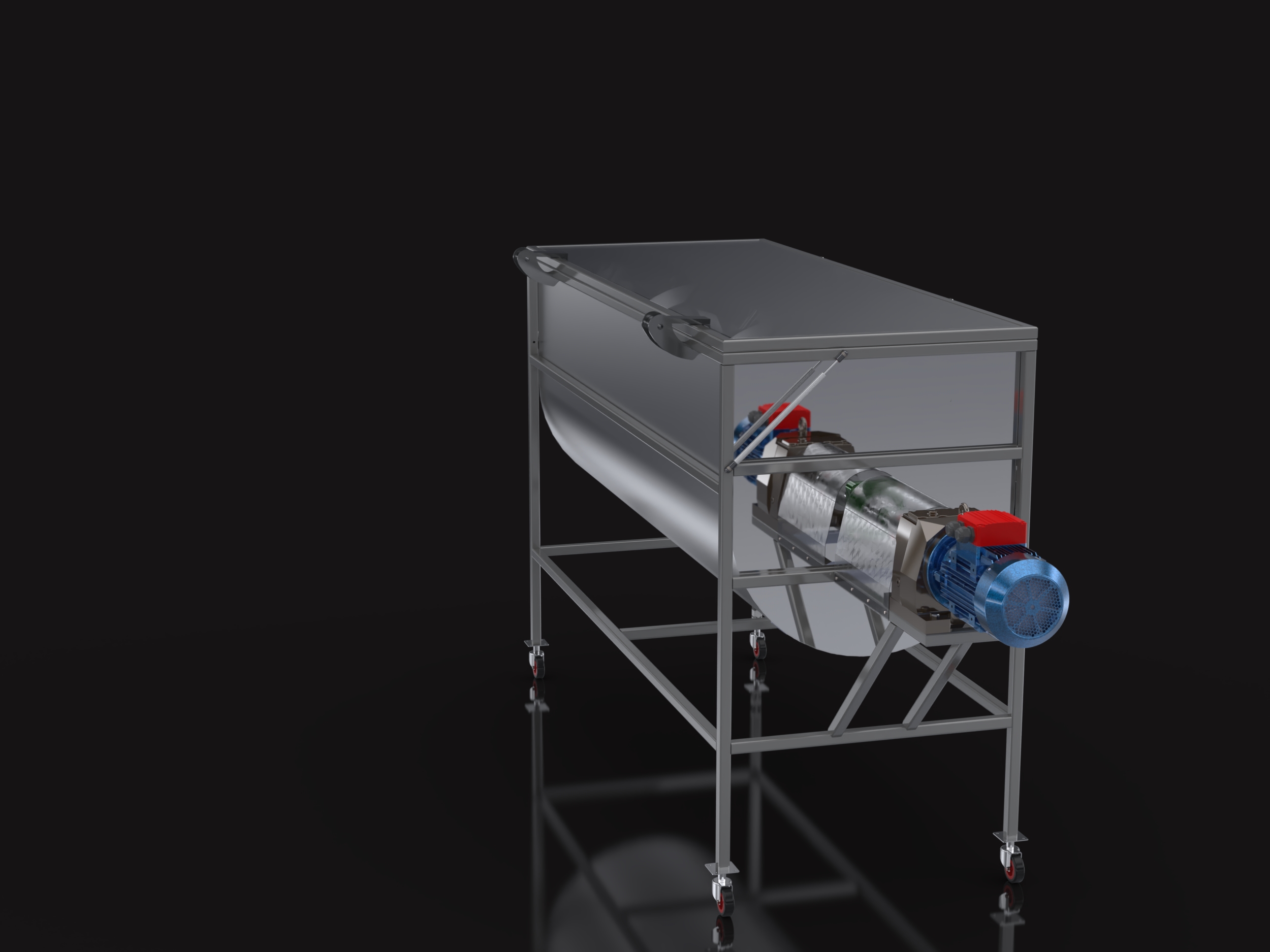

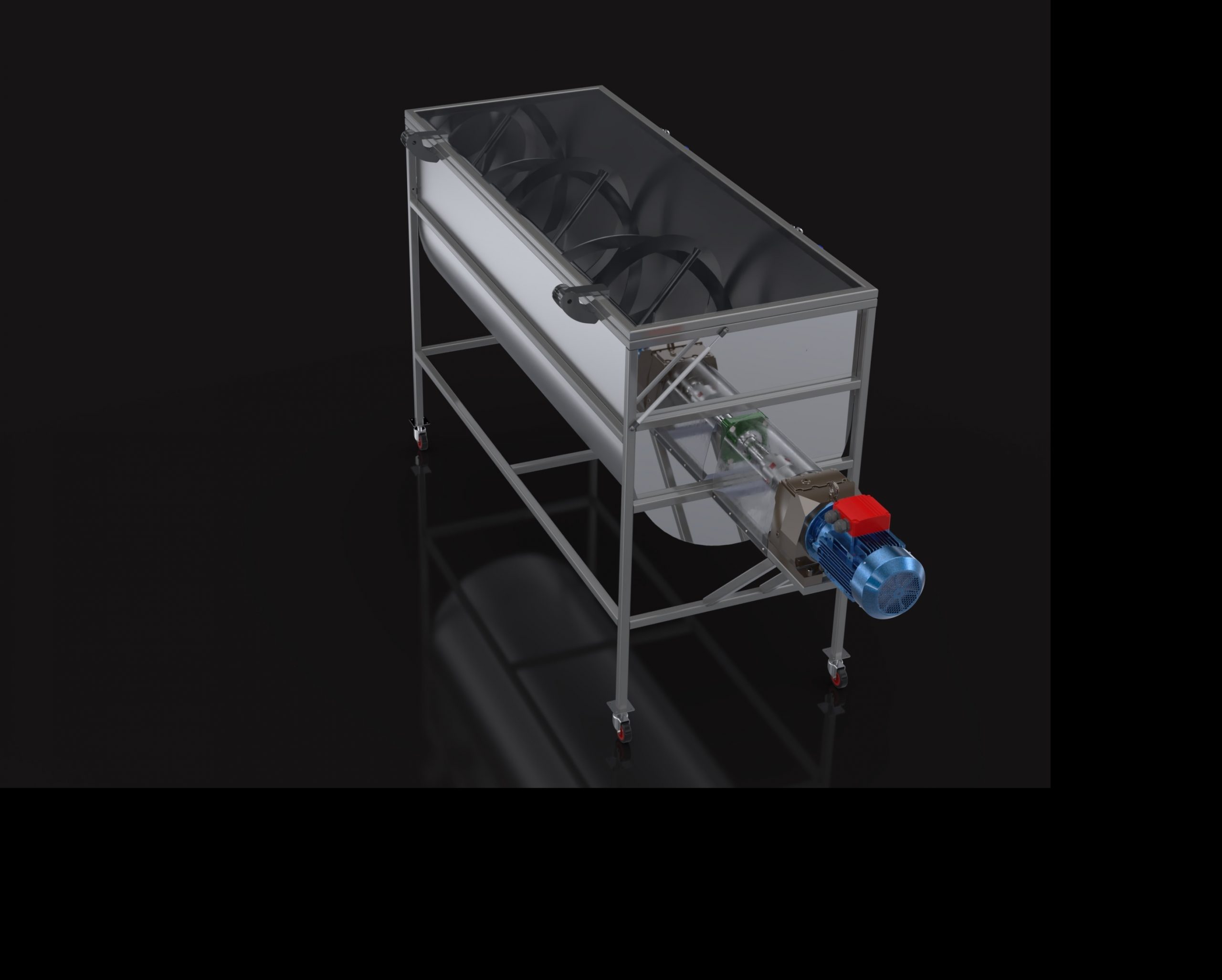

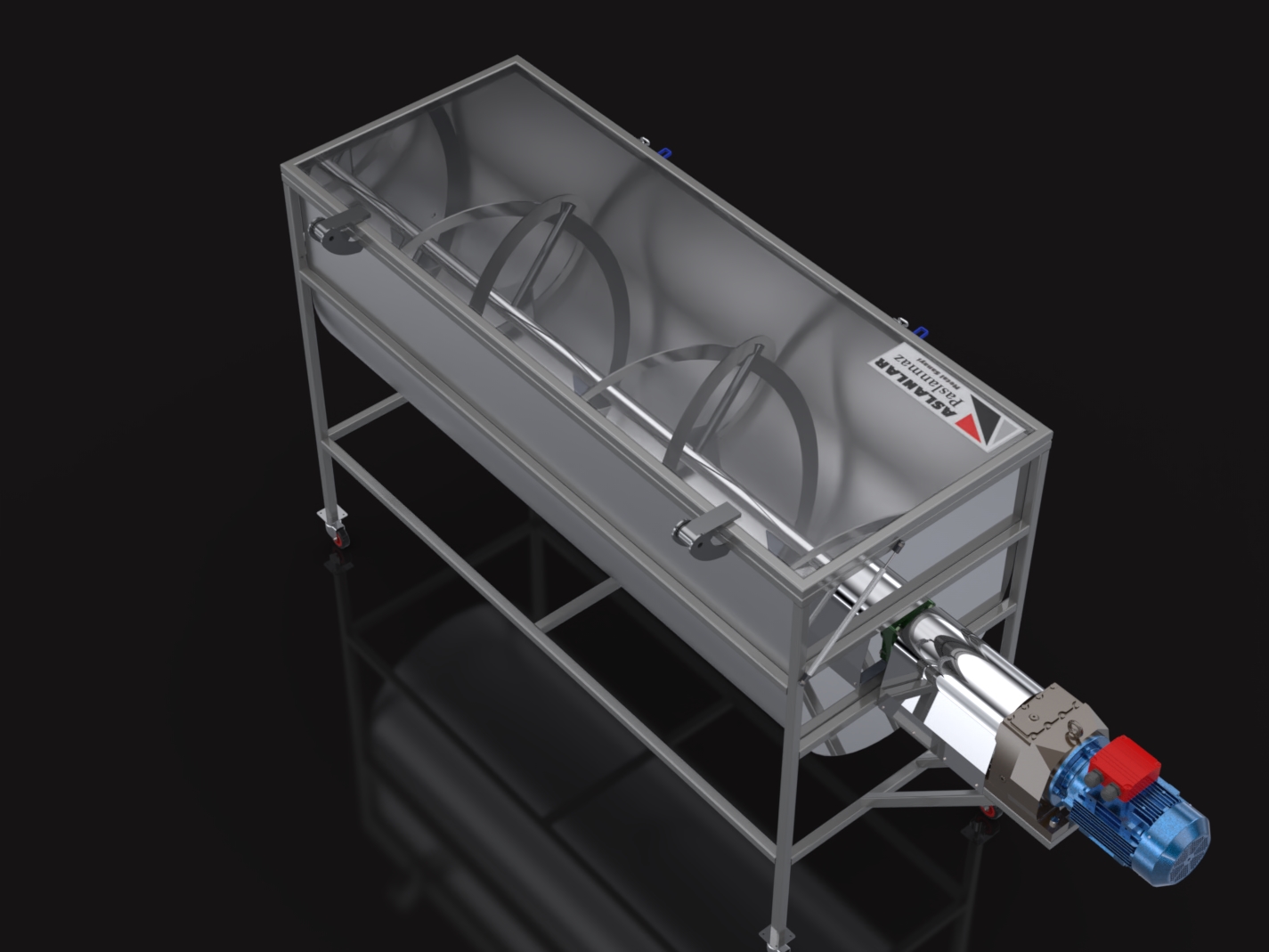

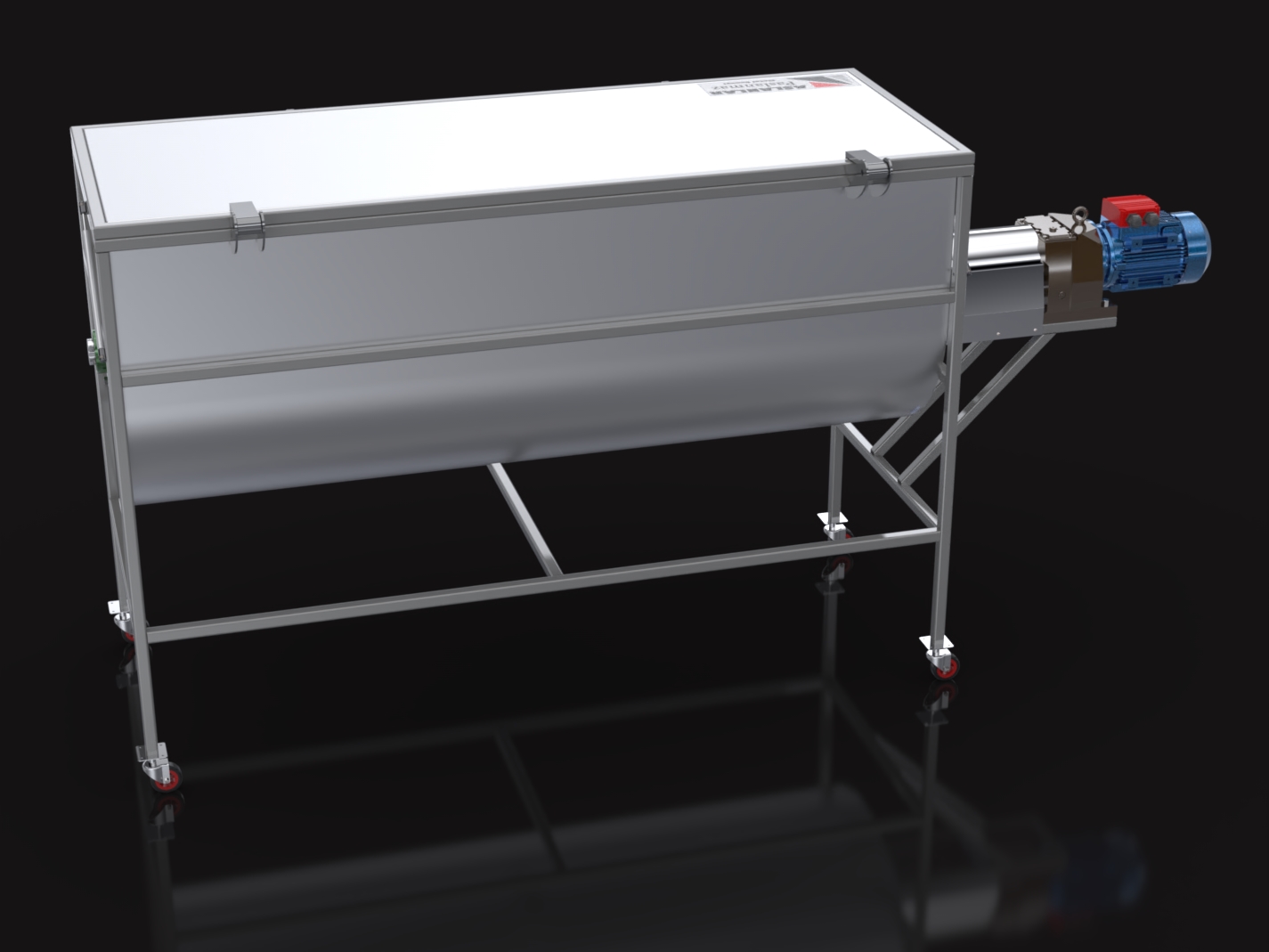

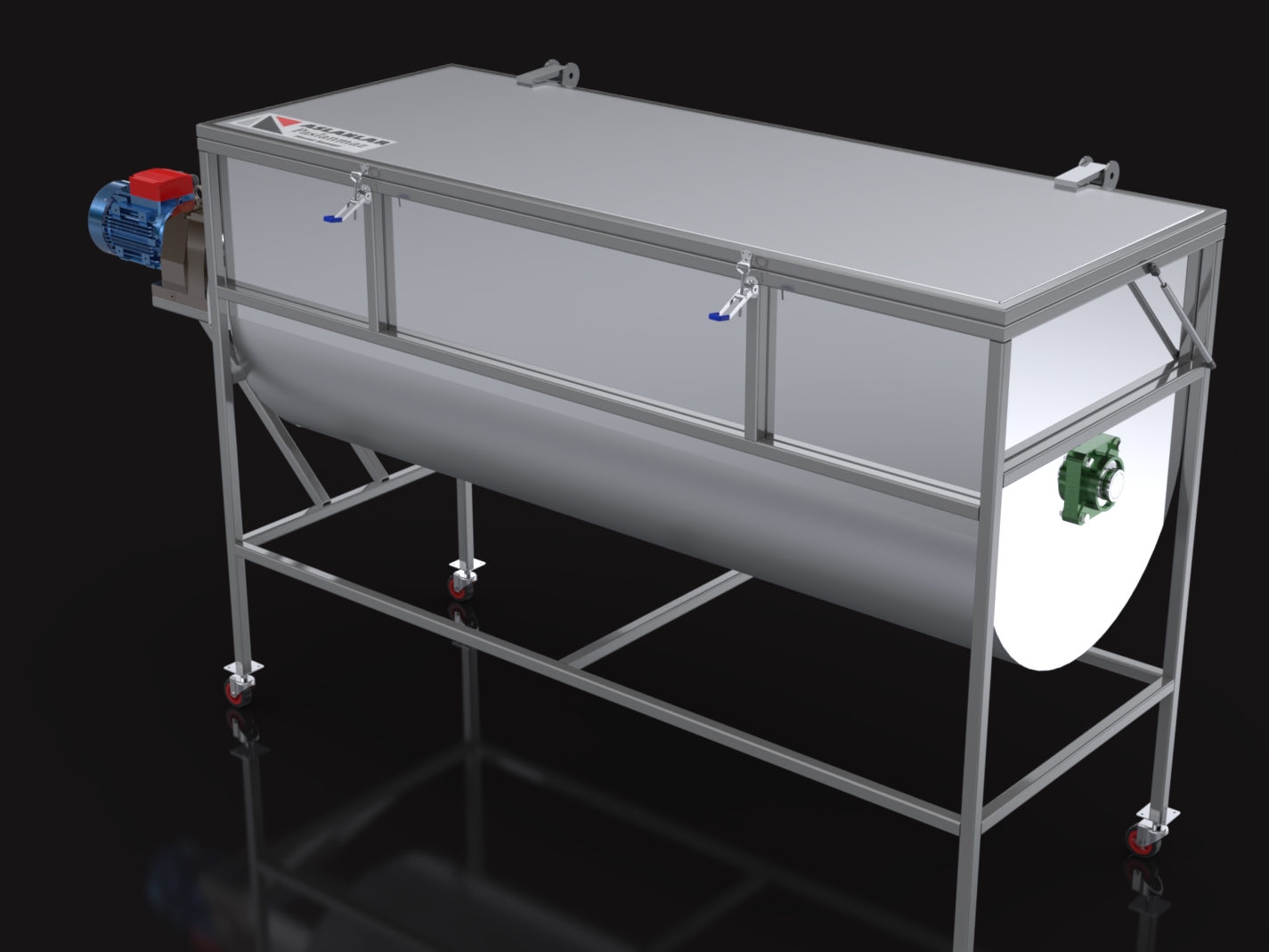

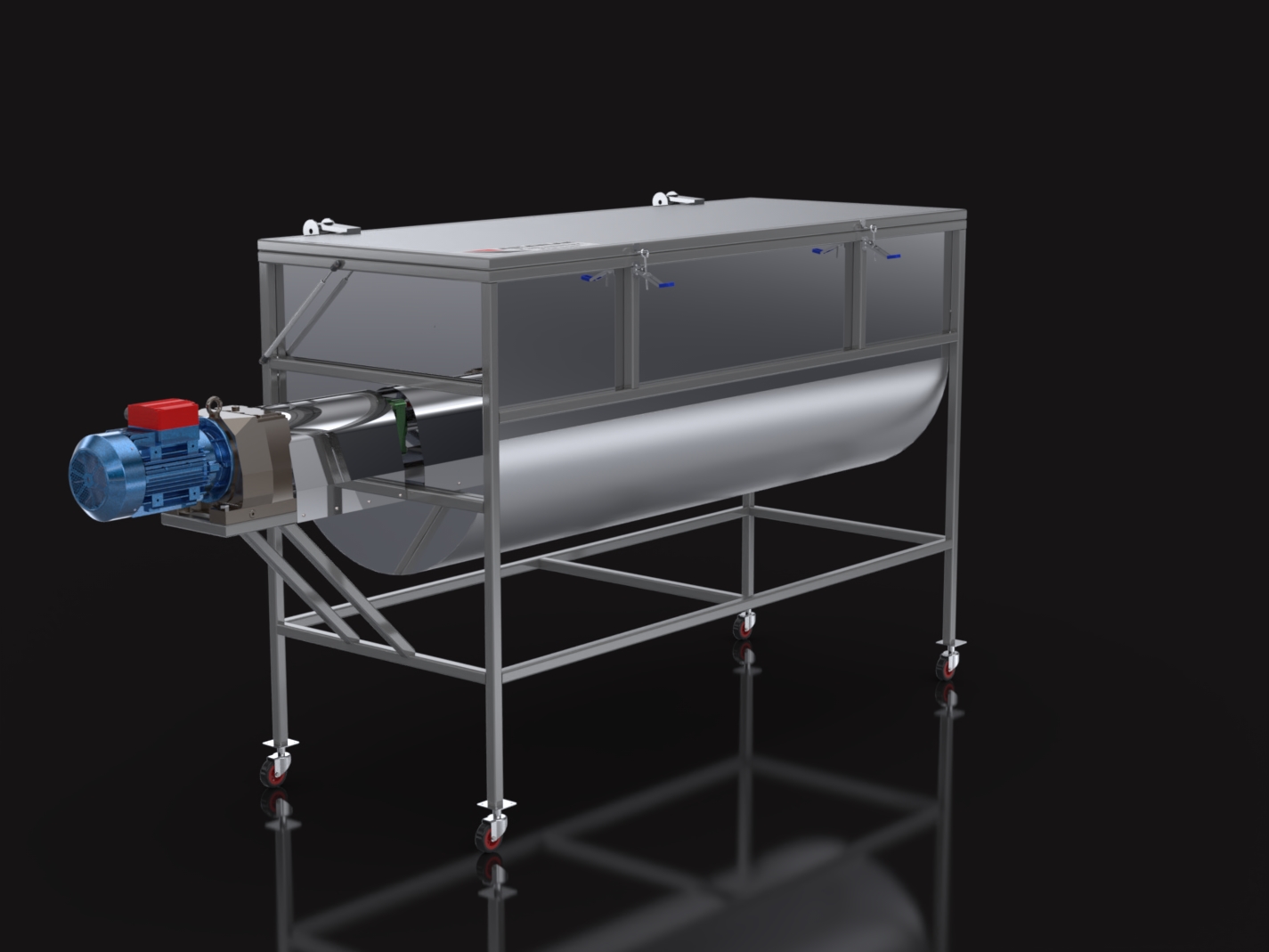

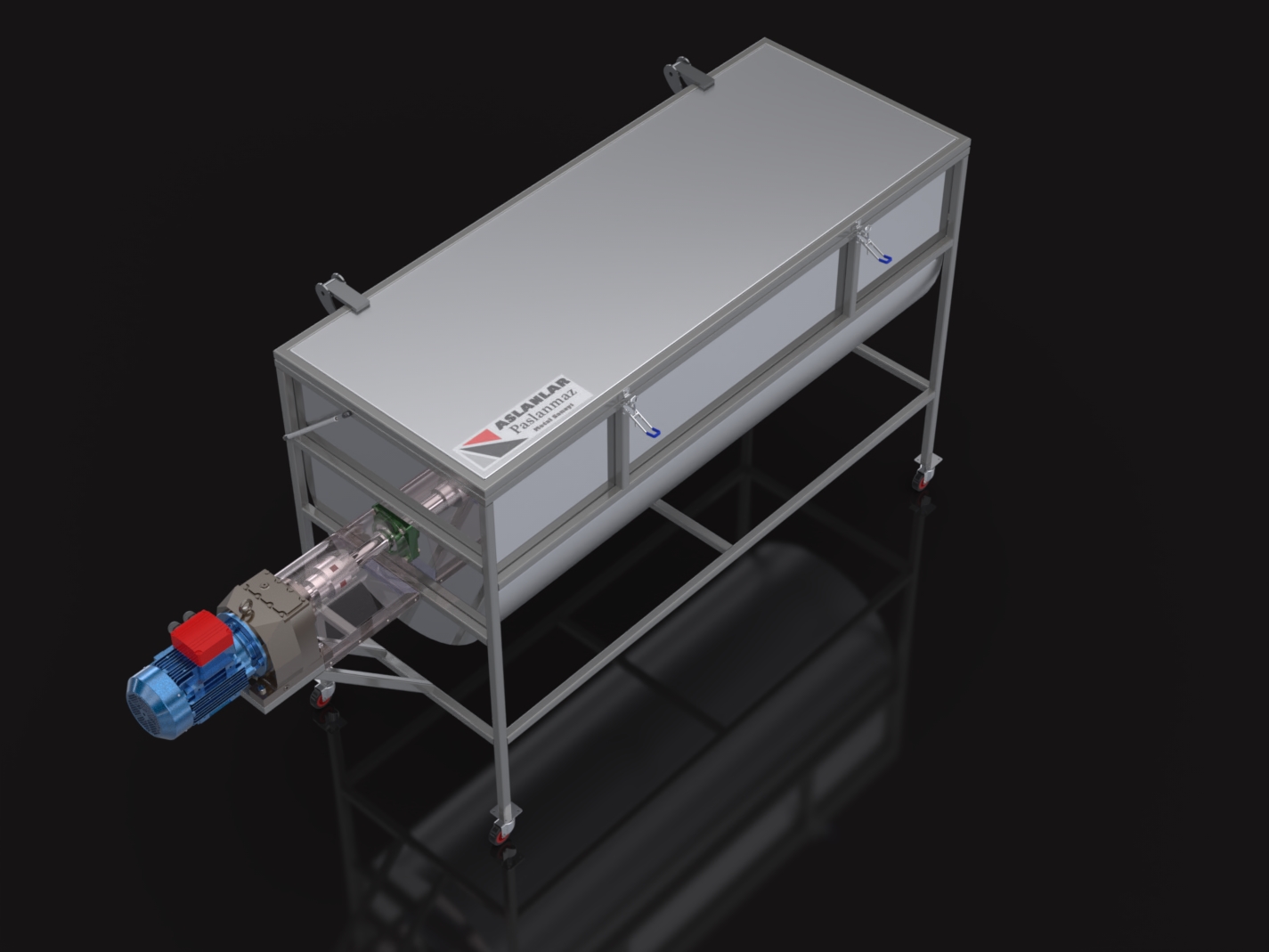

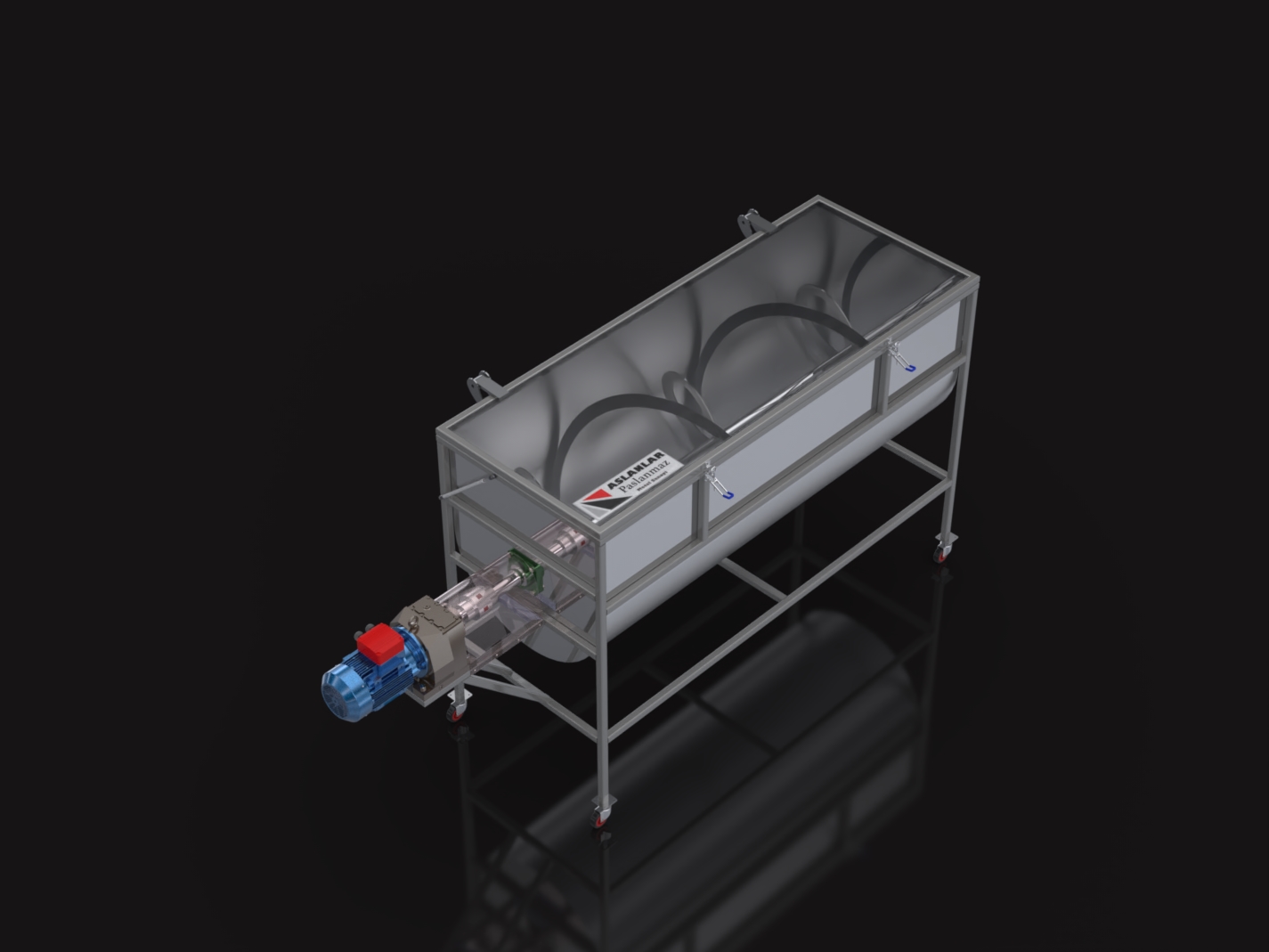

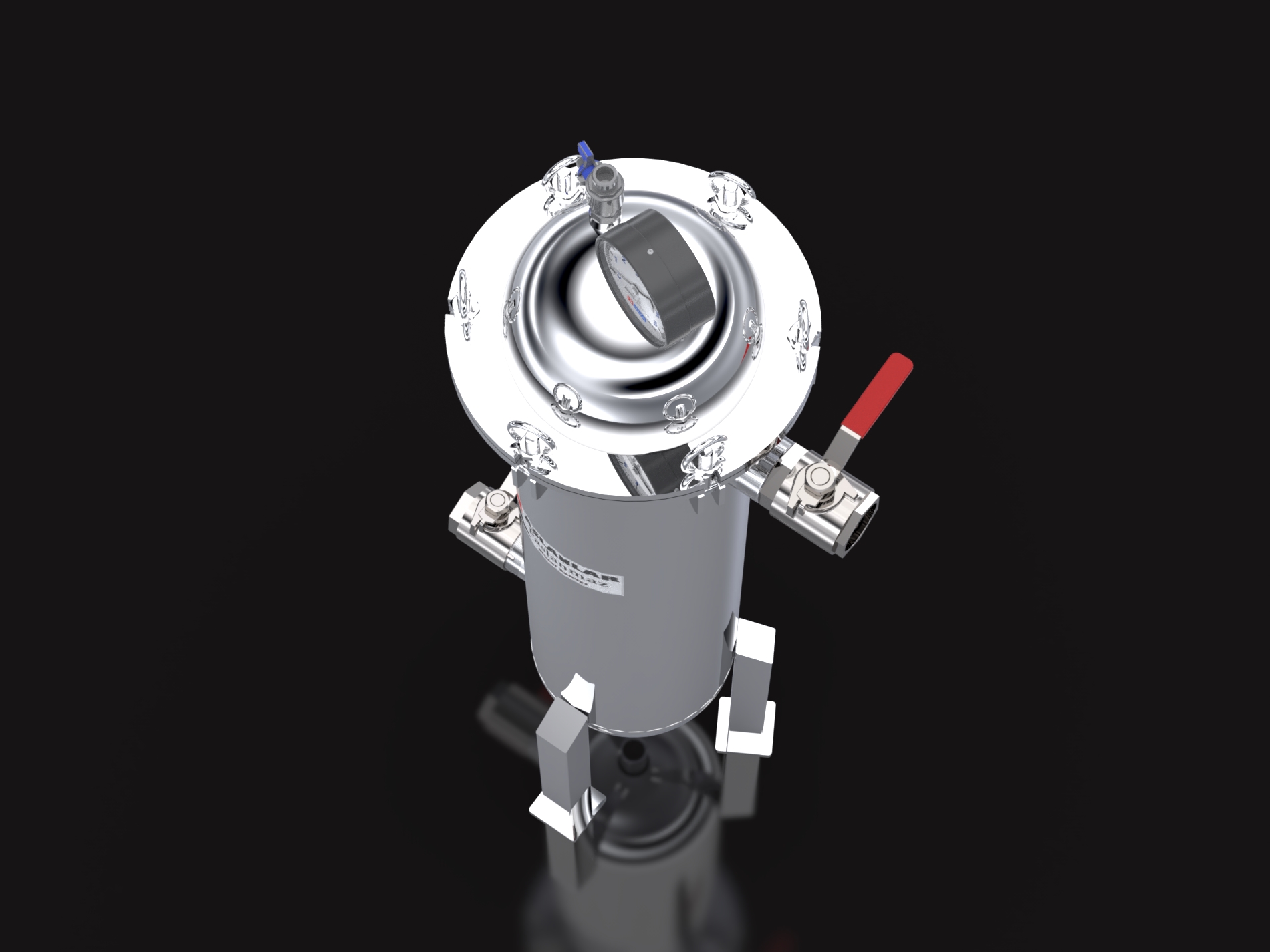

Food industry: Stainless steel is used in the construction of various appliances (e.g. mixers, mixers and cutting boards) and food storage capacities (e.g. refrigerators and freezers) used during food production and processing.

Read More